Double-filler denitrification biological method for reducing nitrous oxide emission and application device

A technology of nitrous oxide and double fillers, applied in biological treatment devices, chemical instruments and methods, sustainable biological treatment, etc., can solve the problem of high return flow, increased power cost investment, unfavorable energy saving and emission reduction, high operating costs, etc. problems, to achieve the effects of reducing production and escape, reducing sludge treatment costs, and improving effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

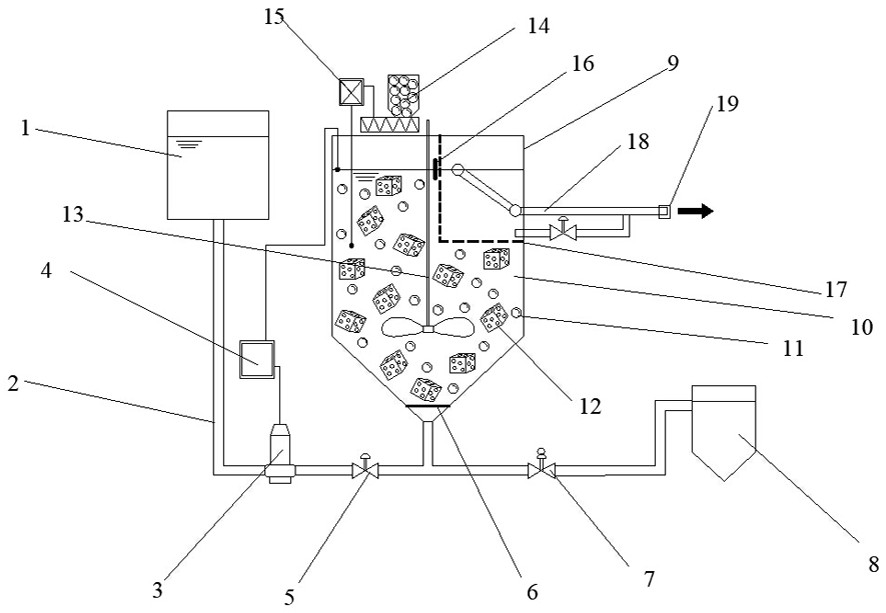

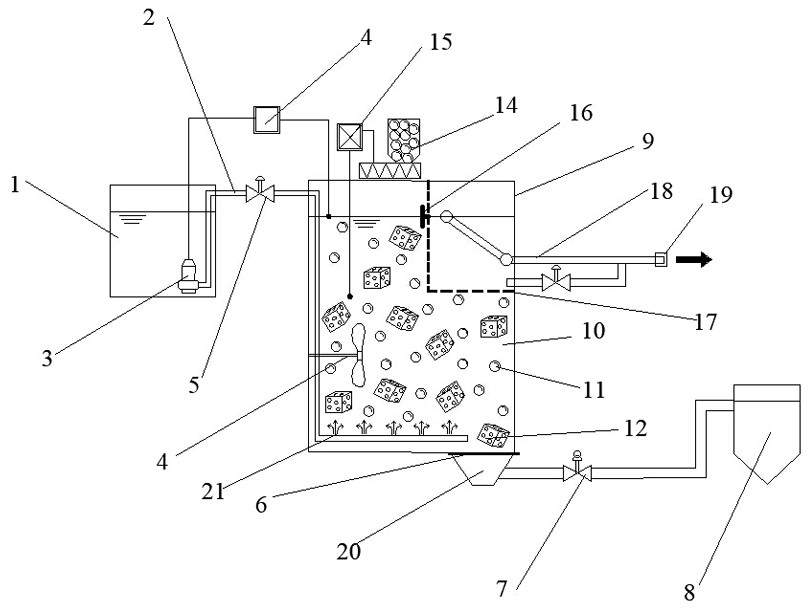

[0042] like Figure 1 to Figure 5 As shown, the use of dual fillers reduces nitrous oxide in wastewater. The application device of double-packed denitrification organisms for reducing nitrous oxide emissions, comprising a reactor 9, a water inlet pond 1 connected to one side of the reactor 9, a sludge pond 8 connected to the other side of the reactor 9, and connected to the reactor 9 The automatic feeder 14 at the top of the reactor 9 and the decanter 18 arranged on the top side of the sewage 10 in the reactor 9.

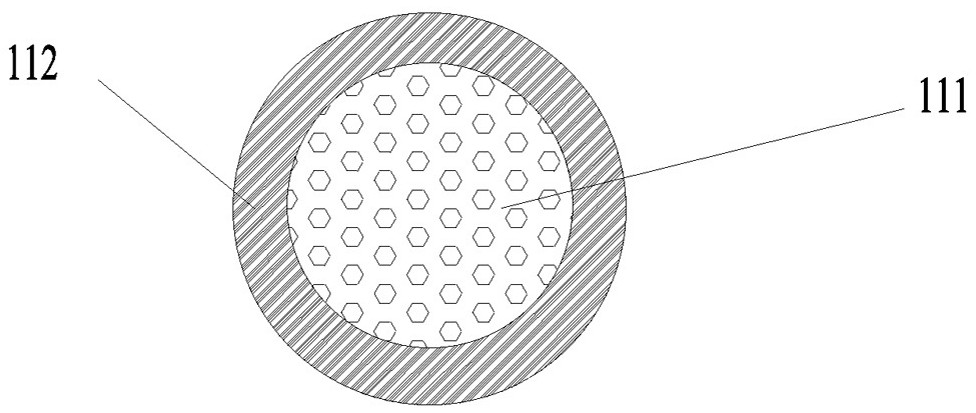

[0043] In this embodiment, the sewage 10 of the reactor 9 is filled with dual fillers, the dual fillers include a first filler 11 and a second filler 12, the first filler 11 is an inorganic internal electrolytic composite material, and the second filler 12 is a porous composite biofilm The carrier and the attached dominant flora filler; the first filler 11 is a sphere, including an inner core 111 and an outer skin 112, the inner core 111 is 0.8~1.0cm light bone cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com