Method for preparing electrode through combination of efficient surface corrosion and graphitization modification

A graphitization and modification technology, applied in electrodes, electrolysis components, electrolysis processes, etc., can solve the problems of high cost of precious metal catalysts, difficult to large-scale commercial application, poor durability, etc., to improve the performance of alkaline hydrogen evolution reaction and improve hydrogen evolution. Catalytic activity, low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

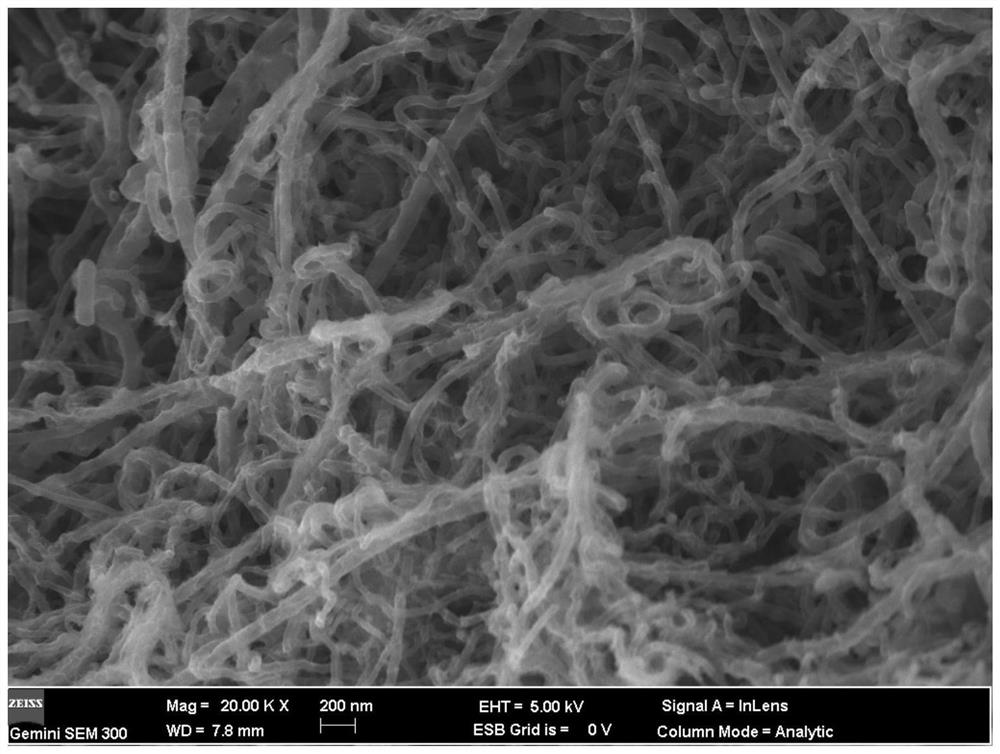

Image

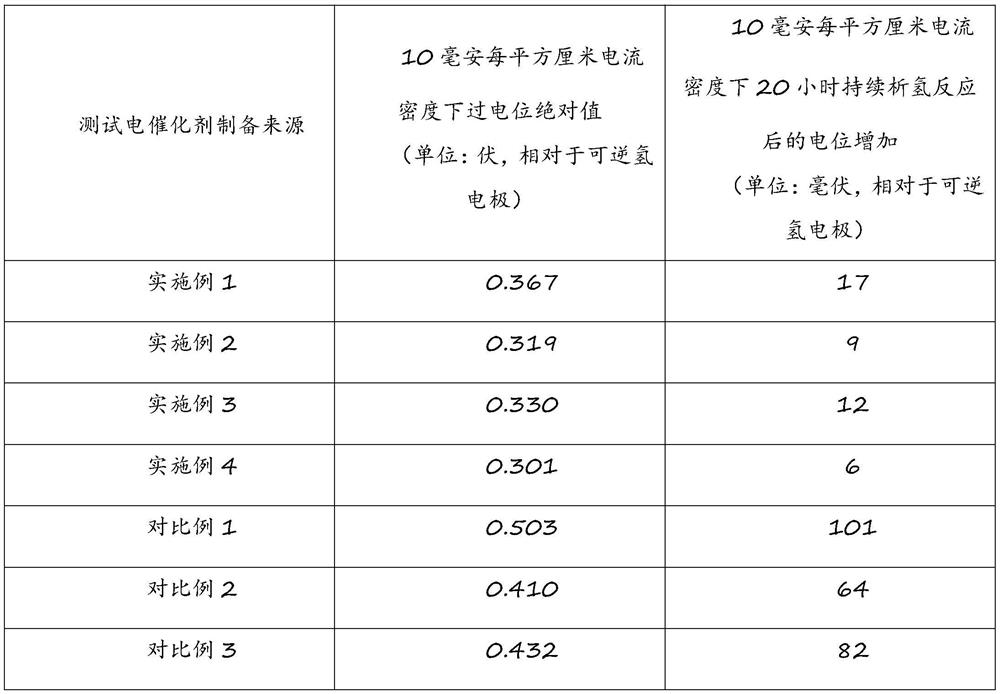

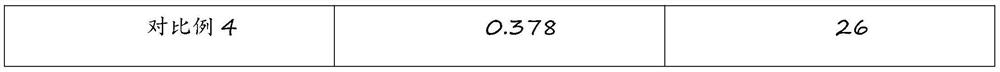

Examples

Embodiment 1

[0028] An electrode preparation method with efficient surface corrosion combined with graphitization modification, using 304 stainless steel sheet as a stainless steel substrate to prepare an electrode as follows:

[0029] The first step: place the 304 stainless steel sheet in acetone solution for ultrasonic cleaning 20min, and then repeatedly clean with ethanol to remove the metal surface grease layer;

[0030] The second step: the 304 stainless steel sheet after removing the grease layer on the metal surface is placed in a hydrochloric acid solution with a concentration of 5 mol / L and ultrasonicated for 10 min, and left to stand for 20 min, and then repeatedly washed with distilled water to remove the oxide layer on the metal surface, and the surface is obtained after drying. 304 stainless steel sheet after cleaning;

[0031] The 3rd step: place the 304 stainless steel sheet after the surface cleaning treatment in a sealed container containing 5mol / L sodium chloride, 0.1mol / ...

Embodiment 2

[0036] An electrode preparation method with efficient surface corrosion combined with graphitization modification, using 316 stainless steel sheet as a stainless steel substrate to prepare an electrode as follows:

[0037] The first step: the 316 stainless steel sheet is placed in acetone solution for ultrasonic cleaning 30min, and then repeatedly cleaned with ethanol to remove the metal surface grease layer;

[0038] The second step: the 316 stainless steel sheet after removing the grease layer on the metal surface is placed in a hydrochloric acid solution with a concentration of 6 mol / L and ultrasonicated for 5 minutes, and left for 25 minutes, and then repeatedly washed with distilled water to remove the oxide layer on the metal surface, and the surface is obtained after drying. 316 stainless steel sheet after cleaning;

[0039] The 3rd step: place the 316 stainless steel sheet after the surface cleaning treatment in a sealed container containing 10mol / L lithium chloride, 0...

Embodiment 3

[0044] An electrode preparation method with efficient surface corrosion combined with graphitization modification, the method for preparing electrodes using 304 stainless steel mesh as a stainless steel substrate is as follows:

[0045] The first step: the 304 stainless steel mesh is placed in the acetone solution for ultrasonic cleaning 10min, and then repeatedly cleaned with ethanol to remove the metal surface grease layer;

[0046] The second step: the 304 stainless steel mesh after removing the grease layer on the metal surface is placed in a hydrochloric acid solution with a concentration of 1 mol / L and ultrasonicated for 20 minutes, and left to stand for 10 minutes, and then repeatedly washed with distilled water to remove the oxide layer on the metal surface, and the surface is obtained after drying. 304 stainless steel mesh after cleaning;

[0047] The third step: place the 304 stainless steel mesh after the surface cleaning treatment in a sealed container containing 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com