Nanometer silicon composite particle, negative plate and solid lithium battery

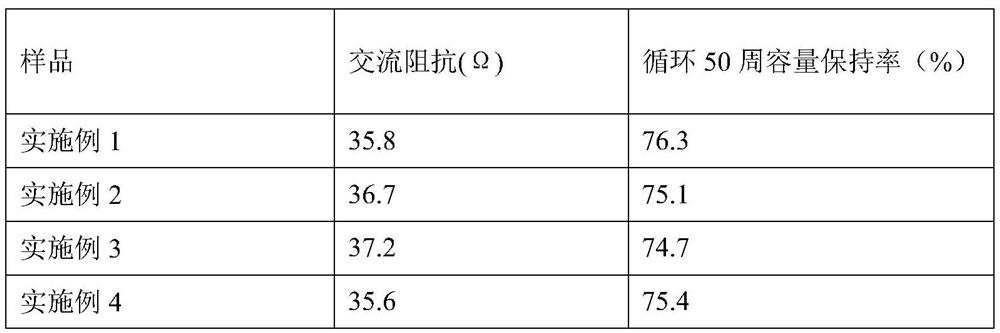

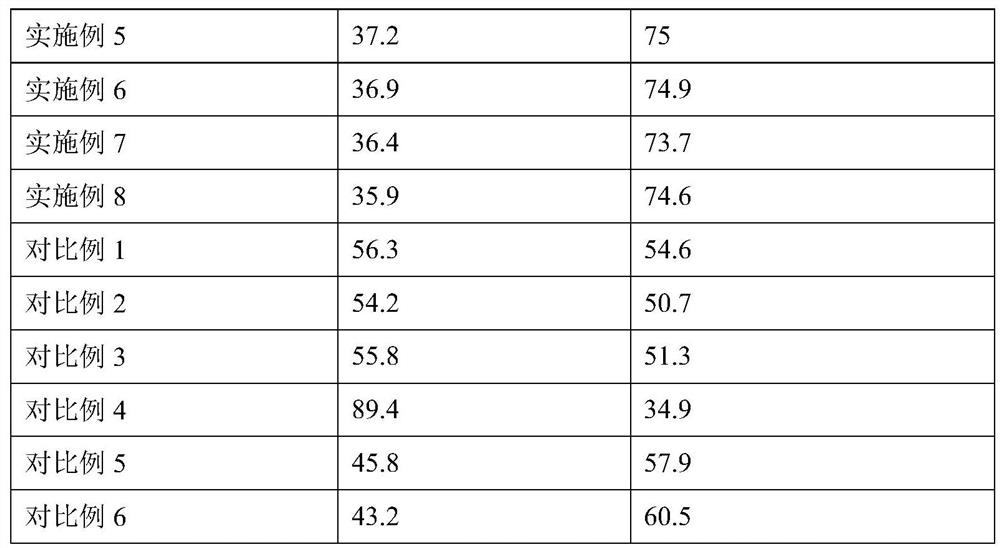

A technology of composite particles and nano-silicon, applied in negative electrodes, nanotechnology, battery electrodes, etc., can solve the problems of low energy density, low theoretical capacity, and poor comprehensive electrochemical performance of lithium-ion batteries. Excellent chemical properties, improved uniformity, and low AC impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation of Nano-Silicon Composite Particles

[0030] A nano-silicon composite particle used as a negative electrode material for a lithium battery, the nano-silicon composite particle is a nano-silicon composite particle modified by N-P-COF-GO, which is a kind of COF and GO interlaced on the surface of silicon nano-particles, N and P Co-doped structure inside COF and GO.

[0031] The preparation method of the nano-silicon composite particles comprises the following steps:

[0032] Disperse silicon nanoparticles, phosphoketene pyruvic acid, acrylamide, and graphene oxide in an organic solvent, the particle size of the silicon nanoparticles is 50 nm (purity greater than 99%), and The mass ratio of acrylamide and graphene oxide is 33:0.002:0.002:1.5, and the organic solvent is a mixed solution of dioxane and trimethylbenzene with a volume ratio of 3:1.

[0033]The above mixture was sonicated at room temperature for 60 minutes, the obtained mixed solution was added...

Embodiment 2

[0040] Compared with Example 1, the particle diameter of silicon nanoparticle is 200nm in the nano-silicon composite particle preparation process in Example 2, and the mass ratio of silicon nanoparticle, phosphoketene pyruvic acid, acrylamide and graphene oxide is 40: 0.003:0.001:0.5; the volume ratio of dioxane to trimethylbenzene was 2:0.7; after ultrasonic mixing at room temperature for 40 minutes, it was rapidly frozen in liquid nitrogen, degassed by a freezing pump-thaw cycle, and the Pyrex tube was placed at 120 Heating in the range of °C for 60 hours; vacuum drying at 60 °C for 4 hours, followed by vacuum sintering at 400 °C for 8 hours; ball milling time for 10 minutes. The remaining conditions are the same as in Example 1.

Embodiment 3

[0042] Compared with Example 1, the acrylamide in the preparation process of the nano-silicon composite particles in Example 3 was replaced by aliphatic n,n-methylenebisacrylamide, and the particle size of the silicon nanoparticles was 500 nm, and the silicon nanoparticles, The mass ratio of phosphoketene pyruvic acid, n,n-methylenebisacrylamide and graphene oxide is 30:0.001:0.003:2.0, and the volume ratio of dioxane to trimethylbenzene is 2.5:0.5; ultrasound at room temperature After mixing for 20 minutes, snap frozen in liquid nitrogen, degassed by a freeze pump-thaw cycle, and heated Pyrex tubes at 80°C for 24 hours; vacuum oven dried at 60°C for 5 hours, followed by vacuum sintering at 350°C 10 hours; ball milling time is 20 minutes. The remaining conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com