Waterproof intermediate cross cable

A cable and cable core technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of blackening and oxidation of conductors, affecting the safe service life of cable products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

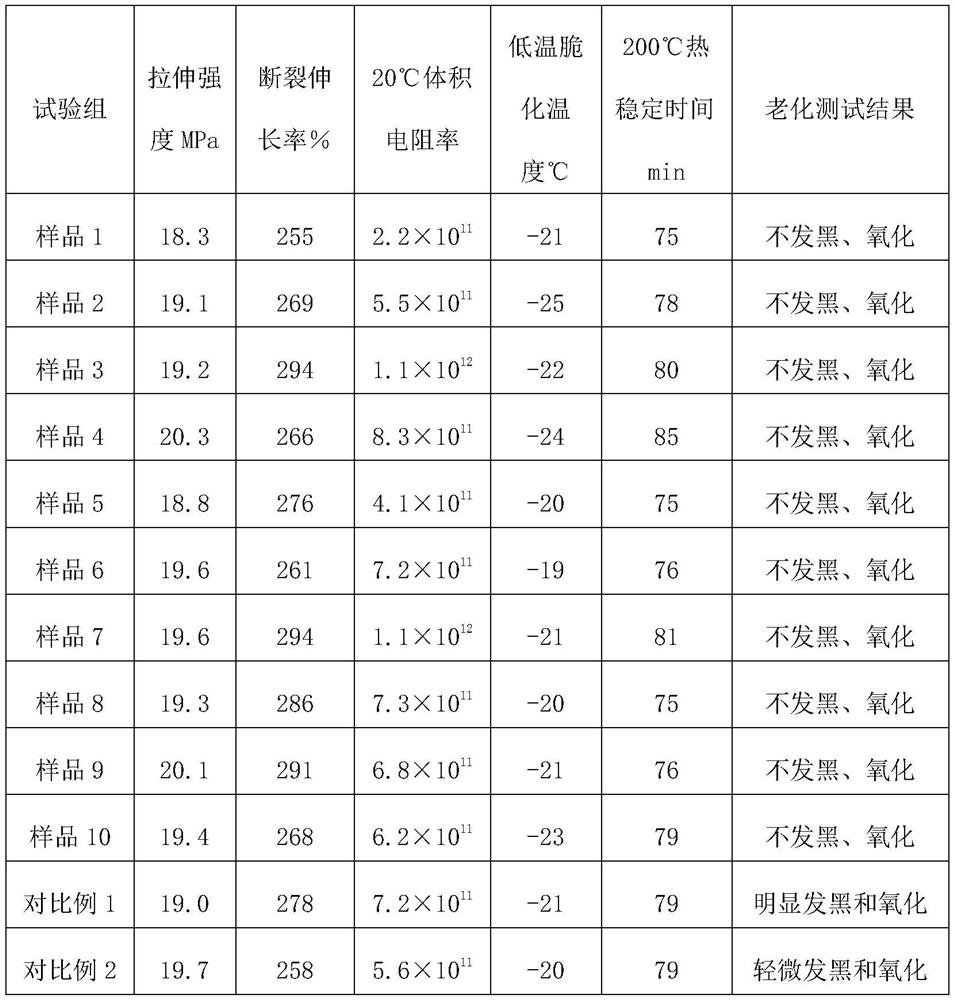

Examples

Embodiment 1

[0042] The utility model relates to a waterproof medium cross cable, which is provided with a cable core body and an anti-copper rust PVC insulation layer wrapped on the outer surface of the cable core.

[0043] The anti-patina PVC insulating layer contains polyvinyl chloride with a polymerization degree of 1000-1300, diisononyl phthalate, epoxy soybean oil, polyethylene wax, anti-patina compatibilizer, modified clay, nano calcium carbonate, anti-corrosion Oxidizers and Colorants.

[0044] The anti-patina compatibilizer includes fullerene, dipropylene dilauryl thio, 2-phenylimidazoline and silane coupling agent.

[0045] The function of the anti-patina compatibilizer of the invention is to prevent oxidation of copper conductors, and in the anti-patina compatibilizer, fullerene and thiodipropylene dilauryl ester cooperate synergistically to produce an anti-oxidation effect. Moreover, both thiodipropylene dilauryl and 2-phenylimidazoline contain active sites capable of coordina...

Embodiment 2

[0061] An anti-patina PVC insulating layer, comprising: polyvinyl chloride with a polymerization degree of 1000-1300, diisononyl phthalate, epoxy soybean oil, polyethylene wax, anti-patina compatibilizer, modified clay , nano calcium carbonate, antioxidants and colorants.

[0062] Anti-patina compatibilizers include fullerene, dipropylenedilauryl thiolate, 2-phenylimidazoline and silane coupling agents

[0063] In parts by weight,

[0064] Polyvinyl chloride: 45 to 50 parts;

[0065] Diisononyl phthalate: 19 to 25 parts;

[0066] Epoxidized soybean oil: 2 to 3 parts;

[0067] Polyethylene wax: 0.1 to 0.2 parts;

[0068] Modified clay: 2 to 6 parts;

[0069] Nano-calcium carbonate: 19 to 25 parts;

[0070] Anti-patina compatibilizer: 2 to 4 parts;

[0071] Antioxidant: 0.2 to 0.5 parts;

[0072] Color paste: 1 to 2 parts.

[0073] The anti-patina compatibilizer contains 25-3 parts of fullerene, 12-14 parts of thiodipropylene dilauryl, 28-32 parts of 2-phenylimidazoline, ...

Embodiment 3

[0076] An anti-patina PVC insulating layer, comprising: polyvinyl chloride with a polymerization degree of 1000-1300, diisononyl phthalate, epoxy soybean oil, polyethylene wax, anti-patina compatibilizer, modified clay , nano calcium carbonate, antioxidants and colorants.

[0077] Anti-patina compatibilizers include fullerene, dipropylenedilauryl thiolate, 2-phenylimidazoline and silane coupling agents

[0078] In parts by weight,

[0079] Polyvinyl chloride: 48.6 parts;

[0080] Diisononyl phthalate: 23.7 parts;

[0081] Epoxidized soybean oil: 2.5 parts;

[0082] Polyethylene wax: 0.18 parts;

[0083] Modified clay: 4 parts;

[0084] Nano calcium carbonate: 23 parts;

[0085] Anti-patina compatibilizer: 3.5 parts;

[0086] Antioxidant: 0.4 parts;

[0087] Color paste: 1.6 parts.

[0088] The anti-patina compatibilizer contains 26 parts of fullerene, 13.6 parts of thiodipropylene dilauryl, 36 parts of 2-phenylimidazoline and 6 parts of silane coupling agent; the anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com