Hollow zinc copper selenide/zinc sulfide/zinc titanate nano composite material as well as preparation method and application thereof

A technology of hollow zinc titanate and empty zinc titanate, which is applied in the field of photocatalysis, can solve the problems of wide band gap of photocatalysts and high recombination rate of photogenerated electrons and holes, and achieve large-scale production, abundant raw material resources, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

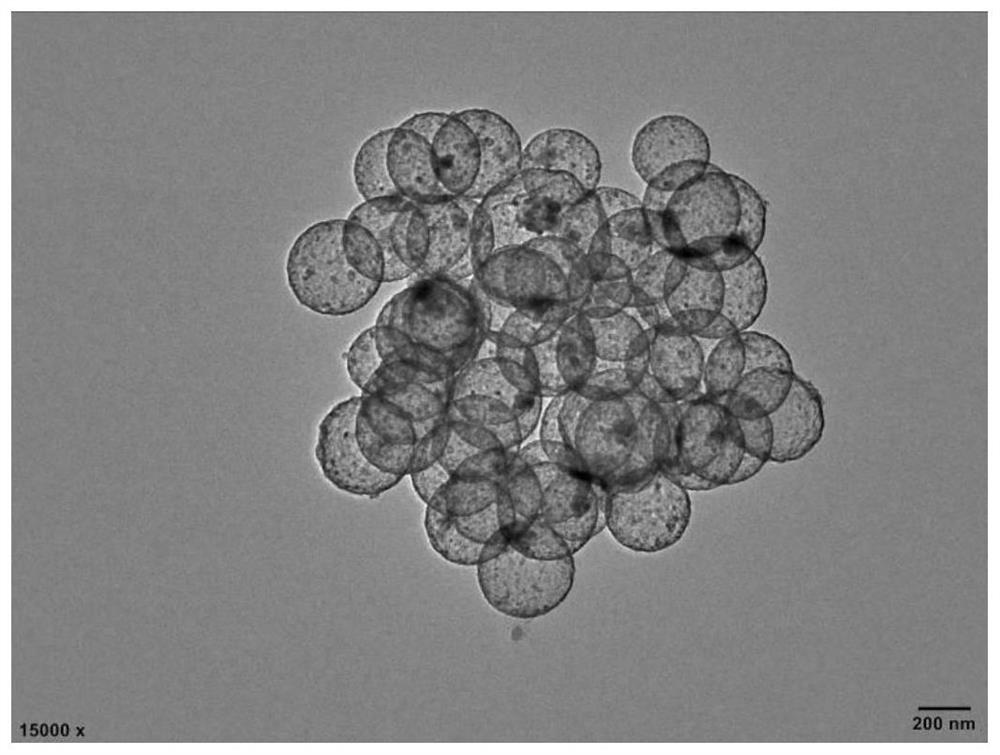

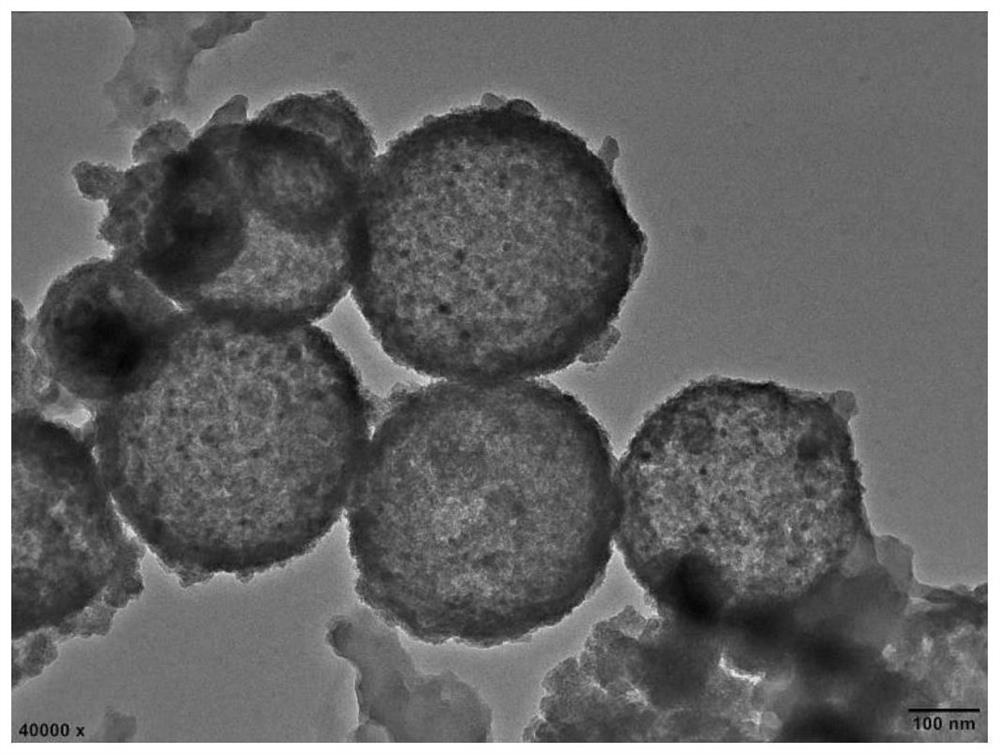

[0029] The present embodiment provides a method for preparing hollow zinc titanate nanospheres, comprising the following steps:

[0030] (1) 0.2217g of zinc acetate was added to 50mL of N,N-dimethylformamide, and dissolved by magnetic stirring to obtain solution A;

[0031] (2) 0.3451mL of tetrabutyl titanate was added to 49.6541mL of absolute ethanol, and dissolved by magnetic stirring to obtain solution B;

[0032] (3) adding the solution A to the solution B, magnetic stirring, after mixing uniformly, adding 0.35g carbon balls, magnetic stirring for 4.5 h, then centrifuging, washing and drying in turn to obtain the zinc titanate;

[0033] (4) put the zinc titanate described in the step (3) into a muffle furnace, select an air atmosphere, the heating rate is 2°C / min, heat to 500°C to start calcination, and calcine for 300min to obtain the hollow zinc titanate Nanospheres.

Embodiment 2

[0035] The present embodiment provides a preparation method of hollow zinc sulfide / zinc titanate, comprising the following steps:

[0036] (1) 0.2217g of zinc acetate was added to 50mL of N,N-dimethylformamide, and dissolved by magnetic stirring to obtain solution A;

[0037] (2) 0.3451mL of tetrabutyl titanate was added to 49.6541mL of absolute ethanol, and dissolved by magnetic stirring to obtain solution B;

[0038] (3) adding the solution A to the solution B, magnetic stirring, after mixing uniformly, adding 0.35g carbon balls, magnetic stirring for 4.5 h, then centrifuging, washing and drying in turn to obtain the zinc titanate;

[0039] (4) put the zinc titanate described in the step (3) into a muffle furnace, select an air atmosphere, the heating rate is 2°C / min, heat to 500°C to start calcination, and calcine for 300min to obtain the hollow zinc titanate Nanospheres.

[0040] (5) 0.0414g of hollow zinc titanate, 0.3496g of zinc chloride and 0.2891g of thioacetamide w...

Embodiment 3

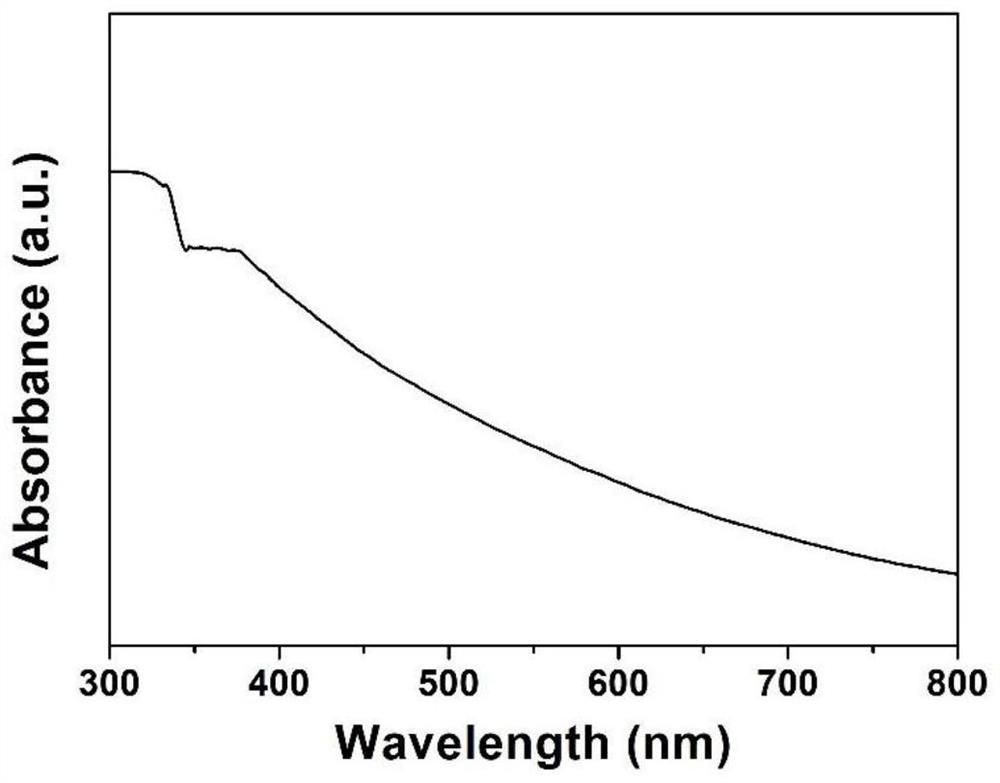

[0042] The present embodiment provides a preparation method of aqueous zinc-copper selenide quantum dots, comprising the following steps:

[0043] (1) 1 mmol Zn(NO 3 ) 2 ·6H 2 O, 1 mmol Cu(NO 3 ) 2 ·3H 2 O, 200 mL of deionized water and 352.1 μL of 3-mercaptopropionic acid were sequentially added to the three-necked flask, stirred evenly, and adjusted to pH 11.00 with 1 M NaOH solution to obtain solution A;

[0044] (2) Take 0.6 mL of NaHSe solution with a concentration of 0.6667M and quickly inject it into solution A, and after the reaction is stable, heat under reflux at 100° C. for 8 hours to obtain the zinc-copper selenide quantum dot solution.

[0045] The steps (1) and (2) are all carried out in a nitrogen atmosphere.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com