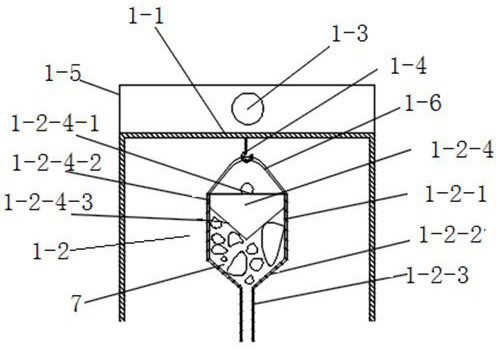

Method and device for doping antimony element in heavily-doped antimony silicon single crystal

An element doping, silicon single crystal technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problem of difficult to achieve heavy antimony doping, slow downflow, quartz funnel funnel burst and other problems, to achieve the effect of improving the primary crystallization rate, reducing the temperature difference and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The single crystal was pulled. After the pulling, the axial and radial resistivity of the single crystal were measured in sections, as shown in Table 3 below. The results show that the antimony element can be doped into the single crystal uniformly and effectively. Under the above conditions, 30 heats of single crystal pulling experiments were carried out, and the primary crystallization rate was counted, and the result was 95%.

[0028] Table 3 Single crystal segmented resistivity test

Embodiment 2

[0029] The single crystal was pulled. After the pulling, the axial and radial resistivity of the single crystal was measured in sections, as shown in Table 4 below. The results show that the antimony element can be uniformly and effectively doped into the single crystal. Under the above conditions, 30 heats of single crystal pulling experiments were carried out, and the primary crystallization rate was counted, and the result was 100%.

[0030] Table 4 Single crystal segmented resistivity test

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com