Method for recycling polylactic acid mixed plastic

A technology of mixing plastics and polylactic acid, which is applied in the direction of plastic recycling, recycling technology, chemical instruments and methods, etc., can solve the problems that the chemical recycling method of polylactic acid cannot meet the requirements of recycling polylactic acid mixed plastics, and achieve low environmental hazards and good bottom Universal applicability, good depolymerization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Sequential depolymerization of plastic bags of PLA / PBAT. The reaction process is as follows:

[0029]

[0030] The first step: depolymerization of polylactic acid in the plastic bag of PLA / PBAT. The specific operation process is as follows:

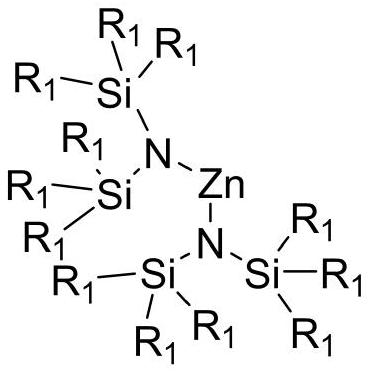

[0031] (1) Take a 100 mL Schlenk bottle, bake it and replace the argon gas, add 12 g of plastic bag fragments in the glove box, add 40 mL of methanol (988 mmol), add 40 mL of dichloromethane solvent, and add 0.6 g of Zn[N (SiMe 3 ) 2 ] 2 Catalyst (5 wt.%), the reaction was stirred at room temperature in a fume hood.

[0032] (2) After 2 hours of reaction, sampling was carried out for NMR monitoring. The results showed that PLA was depolymerized and all converted into methyl lactate, while PBAT was almost not depolymerized, and the characteristic peak of PBAT methanolysis product could not be detected by NMR.

[0033] (3) Separation of product methyl lactate and unreacted PBAT: methanol was added to the reaction s...

Embodiment 2

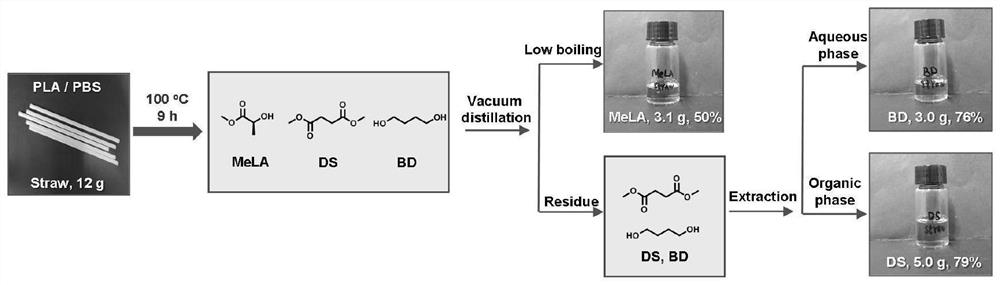

[0041] Example 2: Plastic bag one-pot depolymerization of PLA / PBAT. The reaction process is as follows:

[0042]

[0043] The specific operation process is as follows:

[0044] (1) Take a 100 mL Schlenk bottle, bake it and replace the argon gas, add 12 g (57.1 mmol polymer repeating unit) pieces of plastic bag in the glove box, add 40 mL methanol (988 mmol, 8.7 eq. relative to the polymer ester group), add 40 mL of toluene, add 0.6 g of Zn[N (SiMe 3 ) 2 ] 2 Catalyst (5 wt. %, 1.6 mmol, 2.8 mol % to polymer repeat unit), the reaction was stirred at 100°C in a fume hood.

[0045] (2) After 9 hours of reaction, sampling was carried out for nuclear magnetic detection. The results showed that the conversion rate of PLA was 100%, and the yield of methyl lactate was 100%. The conversion of PBA unit was 78%, the conversion of PBT unit was 95%, and the yield of DMT was 95%.

[0046] (3) separation of reaction product:

[0047] ①Use a vacuum pump to extract and collect lower b...

Embodiment 3

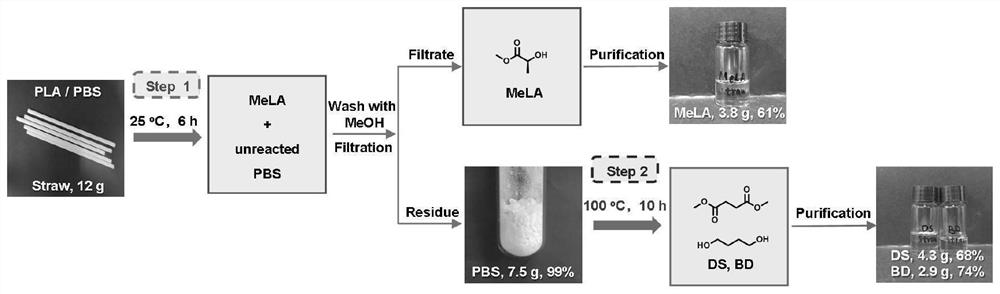

[0050] Example 3: Pipette sequential depolymerization of PLA / PBS. like figure 1 As shown, the reaction process is as follows:

[0051]

[0052] The first step: depolymerization of polylactic acid in the straw of PLA / PBS, the specific operation process is as follows:

[0053] (1) Take a 100 mL Schlenk bottle, bake it and replace the argon gas, add 12 g of pipette fragments in the glove box, add 40 mL of methanol (988 mmol), add 40 mL of dichloromethane solvent, and add 0.6 g of Zn[N ( SiMe 3 ) 2 ] 2 Catalyst (5 wt.%), the reaction was stirred at room temperature in a fume hood.

[0054] (2) After 2 h of reaction, sampling was carried out for NMR monitoring. The results showed that PLA was depolymerized and all converted into methyl lactate, while PBS was almost not depolymerized, and the characteristic peaks of PBAT methanolysis products could not be detected by NMR.

[0055] (3) Separation of product methyl lactate and unreacted PBS: n-hexane was added to the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com