Supramolecular block thin film as well as preparation method and application thereof

A supramolecular and thin-film technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problems of harsh preparation conditions, high actual cost, obstacles to large-scale production and practical application, etc., and achieve good mechanical properties and reduce Sewage treatment cost, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The object of the second aspect of the present invention is to provide a method for preparing the supramolecular bulk thin film, which is prepared by using an ionic surfactant and a polyelectrolyte as raw materials. Specifically include the following steps:

[0054] Step 1. The ionic surfactant is added to the polyelectrolyte aqueous solution, and the reaction is stirred to obtain a suspension containing electrostatic assemblies.

[0055] The selection range of the ionic surfactant and the polyelectrolyte is the same as the selection range of the ionic surfactant and the polyelectrolyte in the first aspect of the present invention.

[0056] The molar concentration of the polyelectrolyte solution is not greater than the molar concentration of the charged polyelectrolyte in the saturated solution of the polyelectrolyte, preferably 0.001 mM-80 mM, more preferably 1-50 mM. The polyelectrolyte solution molarity is measured by the molarity of the charged polyelectrolyte in i...

Embodiment 1

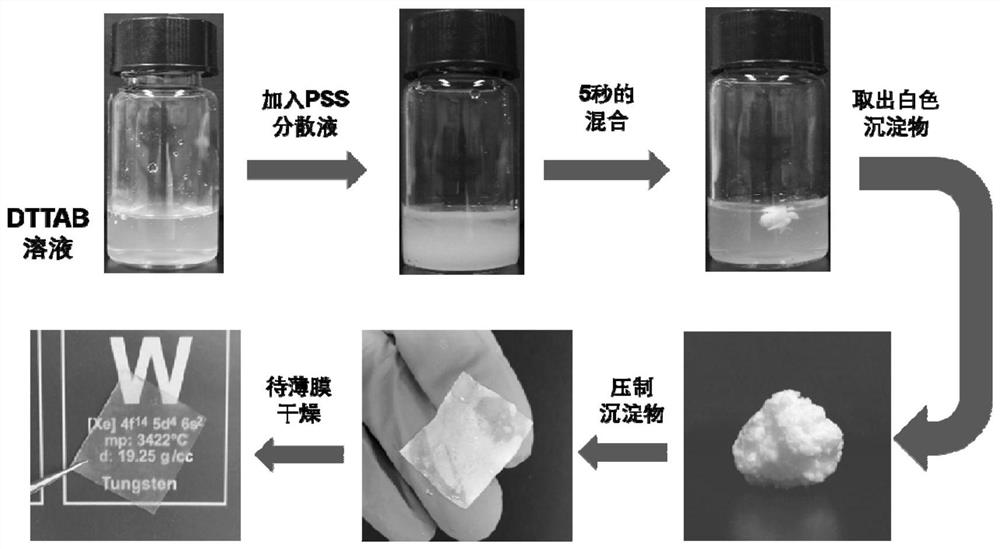

[0090] Dissolve polystyrene sodium sulfonate (PSS) solid in water to obtain a PSS aqueous solution with a negative charge concentration of 20 mM, then add ditetradecyldimethylammonium bromide (DTTAB) solid powder into the above solution, control The amount added was such that the DTTAB cation concentration in the solution was also 20 mM.

[0091] The two components were fully mixed by stirring and shaking, and a large number of white flocculent precipitates appeared in the solution. The suspension was centrifuged at 5000rpm to obtain white precipitates of PSS / DTTAB electrostatic assemblies stacked together. The specific process is as follows: figure 1 shown.

Embodiment 2

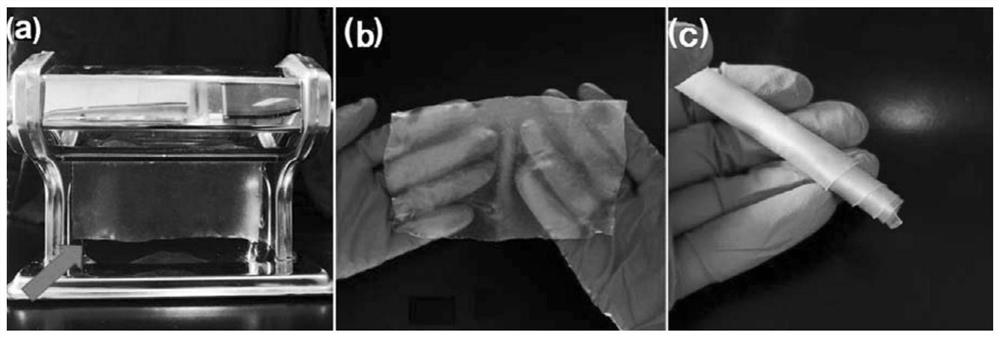

[0093] The PSS / DTTAB electrostatic assembly obtained in Example 1 was placed on a glass substrate, covered with another piece of glass, and pressed with fingers for 10 seconds, then the pressure was stopped.

[0094] When the upper glass is removed, it can be found that the original loose white PSS / DTTAB electrostatic assembly has been transformed into a transparent film, and the film is peeled off from the glass substrate to obtain a PSS / DTTAB supramolecular block film with complete morphology, PSS / DTTAB supramolecular block Macrophotographs of bulk films such as figure 1 shown.

[0095] The PSS / CTAB supramolecular bulk film was easily peeled off from the glass substrate, indicating that the film has good self-supporting properties. The two ends of the PSS / CTAB film are aligned and bent with tweezers, and the film can be quickly restored to its original shape after the tweezers are released, indicating that the film has good bendability and recovery.

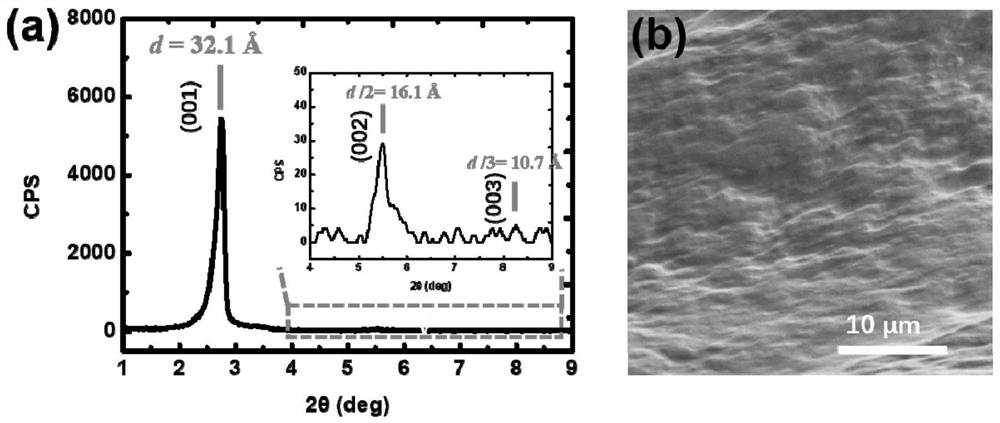

[0096] The PSS / DTTAB ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com