Modified soybean lecithin drilling fluid lubricant and preparation method thereof

A soybean lecithin and drilling fluid technology, which is applied in the field of petroleum drilling fluid, can solve the problems of reducing the utilization rate of soybean lecithin, limited improvement of lecithin water dispersion ability, and few hydrophilic groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

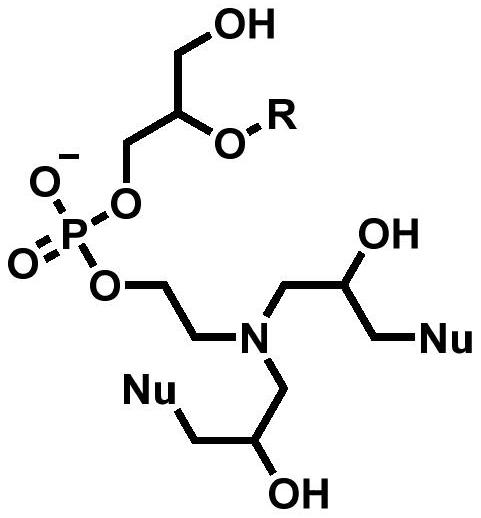

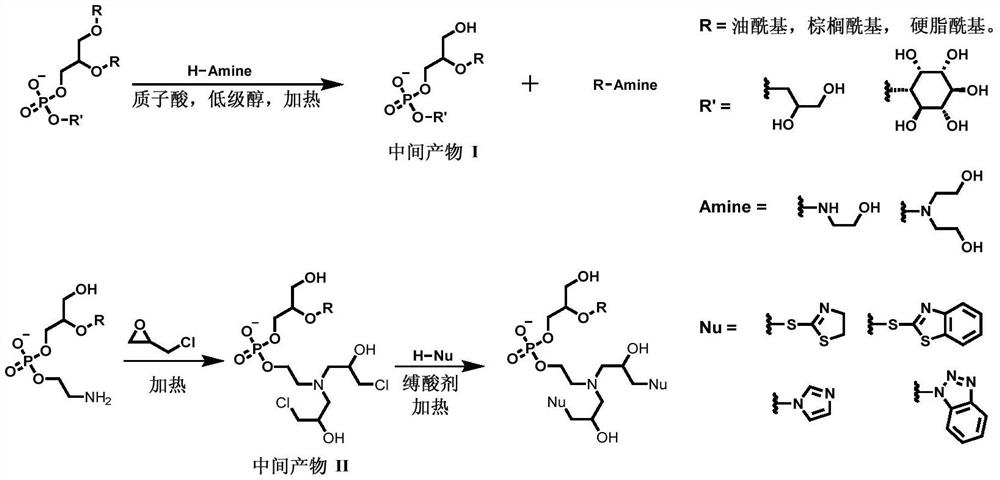

Method used

Image

Examples

Embodiment 1

[0027] Mix 50 g of soybean lecithin with 80 mL of ethanol, form a dispersion under heating at 80 °C, add 7.0 g of diethanolamine and 0.1 g of p-toluenesulfonic acid, heat under reflux at 80 °C for 6 hours, and add 4.0 g of epichlorohydrin. After heating at 60°C for 3 hours, 3.0 g of potassium carbonate and 5.0 g of 2-mercaptothiazoline were added. After heating at 60°C for 12 hours, the solvent ethanol was distilled off under reduced pressure to obtain the final soybean lecithin modified lubricant.

Embodiment 2

[0029] Mix 50 g of soybean lecithin with 80 mL of ethanol, form a dispersion under heating at 80 °C, add 7.0 g of diethanolamine and 0.1 g of p-toluenesulfonic acid, heat under reflux at 80 °C for 6 hours, and add 4.0 g of epichlorohydrin. After heating at 60 °C for 3 hours, 3.0 g of potassium carbonate and 7.0 g of 2-mercaptobenzothiazole were added, and after heating at 80 °C for 8 hours, the solvent ethanol was distilled off under reduced pressure to obtain the final soybean lecithin modified lubricant.

Embodiment 3

[0031] Mix 50g soybean lecithin with 120mL ethanol, form a dispersion under heating at 80°C, add 7.0g diethanolamine, 0.1g sulfuric acid, heat under reflux at 80°C for 6 hours, add 4.0g epichlorohydrin, heat at 60°C After 3 hours of reaction, 2.0 g of sodium carbonate and 3.0 g of imidazole were added, and after heating at 60°C for 6 hours, the solvent ethanol was distilled off under reduced pressure to obtain the final soybean lecithin modified lubricant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com