Near-infrared luminescent material as well as preparation method and application thereof

A light-emitting material and near-infrared technology, applied in the field of fluorescent materials, can solve problems such as poor chemical stability, fluorescence heat quenching, and low luminous efficiency, and achieve the effects of low cost, easy operation, and simple and feasible methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] This embodiment provides a near-infrared light-emitting material, and the chemical formula of the near-infrared light-emitting material is K 0.97 Ga 10.95 Cr 0.05 Yb 0.03 O 17 .

[0061] The preparation of the near-infrared light-emitting material is as follows:

[0062] (1) weighing potassium carbonate, gallium oxide, chromium oxide and ytterbium oxide in a stoichiometric ratio of K:Ga:Cr:Yb=1.94:10.95:0.05:0.03 in a molar ratio, grinding and mixing to obtain a mixture;

[0063] (2) Put the mixture obtained in step (1) into an alumina crucible, calcinate at 1500° C. for 4 hours, take out when cooled to room temperature, and grind and disperse to obtain near-infrared light-emitting material K 0.97 Ga 10.95 Cr 0.05 Yb 0.03 O 17 .

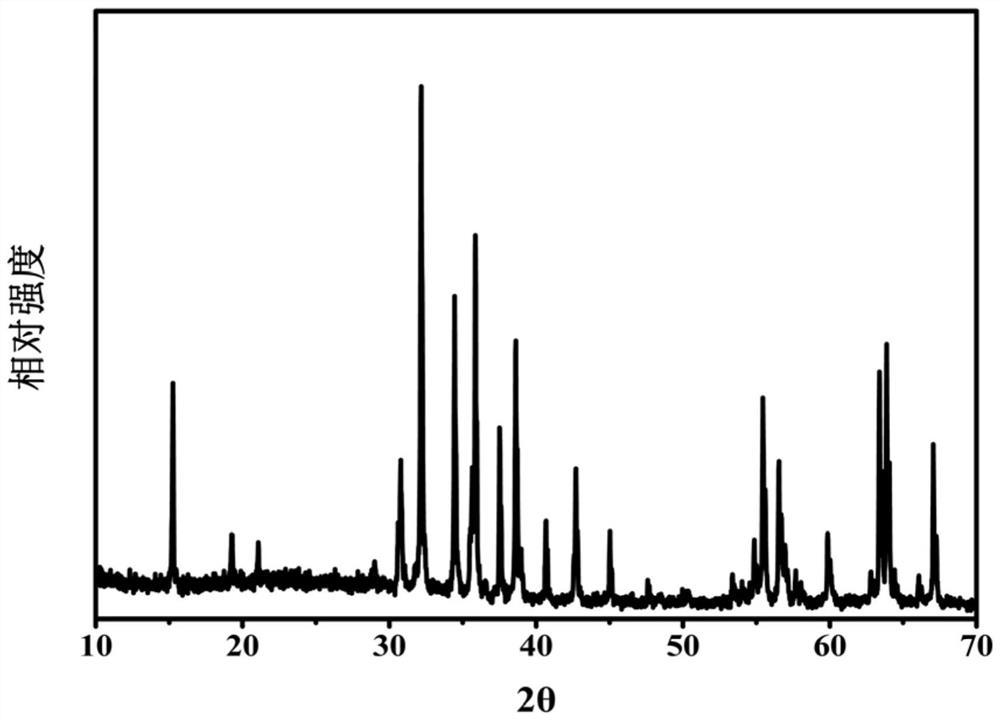

[0064] figure 1 The XRD pattern of the near-infrared light-emitting material obtained in Example 1 is shown. It can be seen from the figure that the spectrum is similar to that of KGa. 11 O 17 Consistent with the proof that succes...

Embodiment 2

[0068] This embodiment provides a near-infrared light-emitting material, and the chemical formula of the near-infrared light-emitting material is K 0.98 Al 10.87 Cr 0.13 Yb 0.02 O 17 .

[0069] The preparation of the near-infrared light-emitting material is as follows:

[0070] (1) weighing potassium carbonate, aluminum oxide, chromium oxide and ytterbium oxide with a stoichiometric ratio of K:Al:Cr:Yb=1.96:10.87:0.13:0.02, grinding and mixing to obtain a mixture;

[0071] (2) Put the mixture obtained in step (1) into an alumina crucible, calcinate at 1500° C. for 8 hours, take out when cooled to room temperature, grind and disperse to obtain near-infrared light-emitting material K 0.98 Al 10.87 Cr 0.13 Yb 0.02 O 17 .

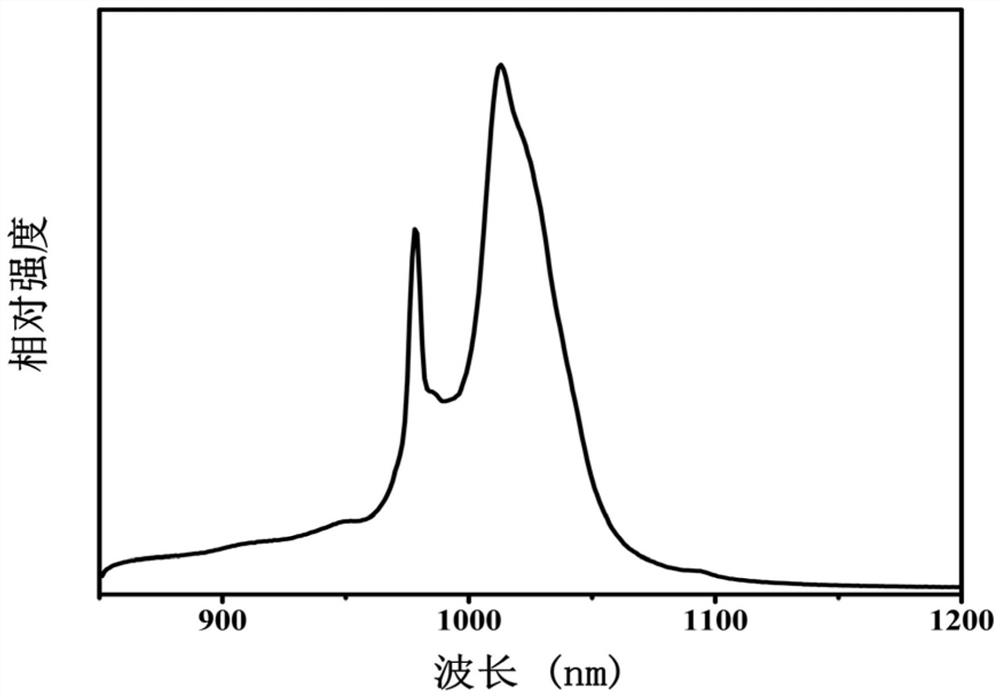

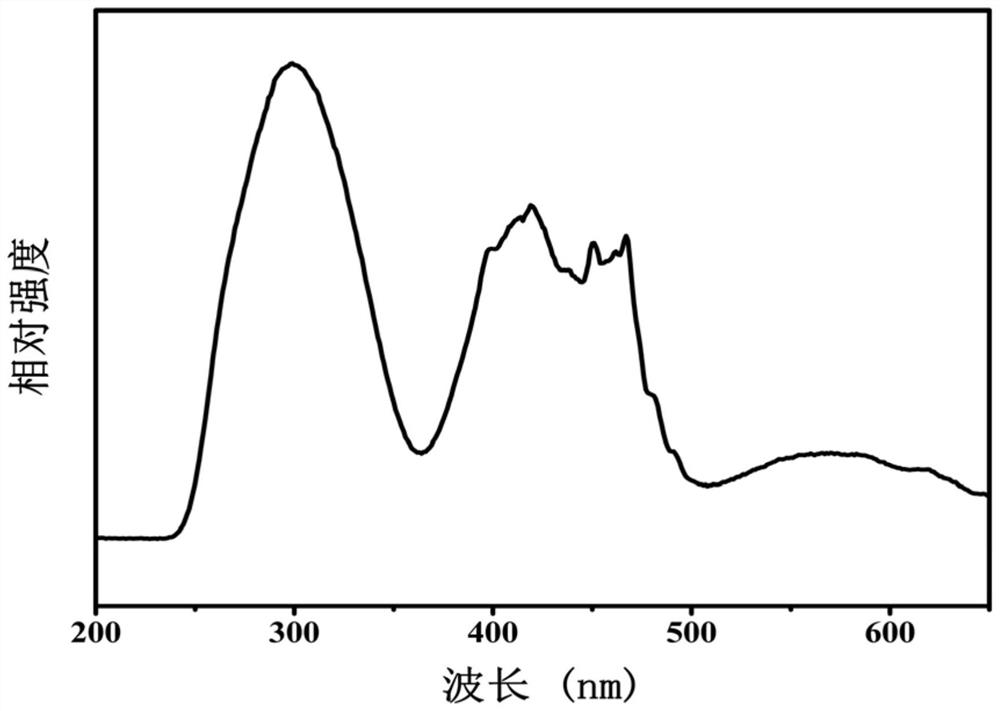

[0072] Figure 4 The luminescence spectrum of the near-infrared light-emitting material obtained in Example 2 shows the photoluminescence emission of the near-infrared light-emitting material under the excitation condition of 420 nm blue light, and t...

Embodiment 3

[0076] This embodiment provides a near-infrared light-emitting material, and the chemical formula of the near-infrared light-emitting material is Li 0.97 Ga 10.95 Cr 0.05 Yb 0.03 O 17 .

[0077] The preparation of the near-infrared light-emitting material is as follows:

[0078] (1) Weigh lithium carbonate, gallium oxide, chromium oxide and ytterbium oxide in a stoichiometric ratio of Li:Ga:Cr:Yb=1.94:10.95:0.05:0.03 in molar ratio, and grind and mix to obtain a mixture;

[0079] (2) Put the mixture obtained in step (1) into an alumina crucible, calcinate at 1500° C. for 6 hours, take out when cooled to room temperature, grind and disperse to obtain a near-infrared light-emitting material Li 0.97 Ga 10.95 Cr 0.05 Yb 0.03 O 17 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com