Preparation method of hexose-6-phosphoric acid composition and application of hexose-6-phosphoric acid composition in cosmetics

A technology of composition and phosphoric acid, which is applied in the direction of cosmetics, cosmetic preparations, medical preparations containing active ingredients, etc., can solve the problems of different timeliness, etc., and achieve the effect of reducing process difficulty, saving production cost, and reducing process routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

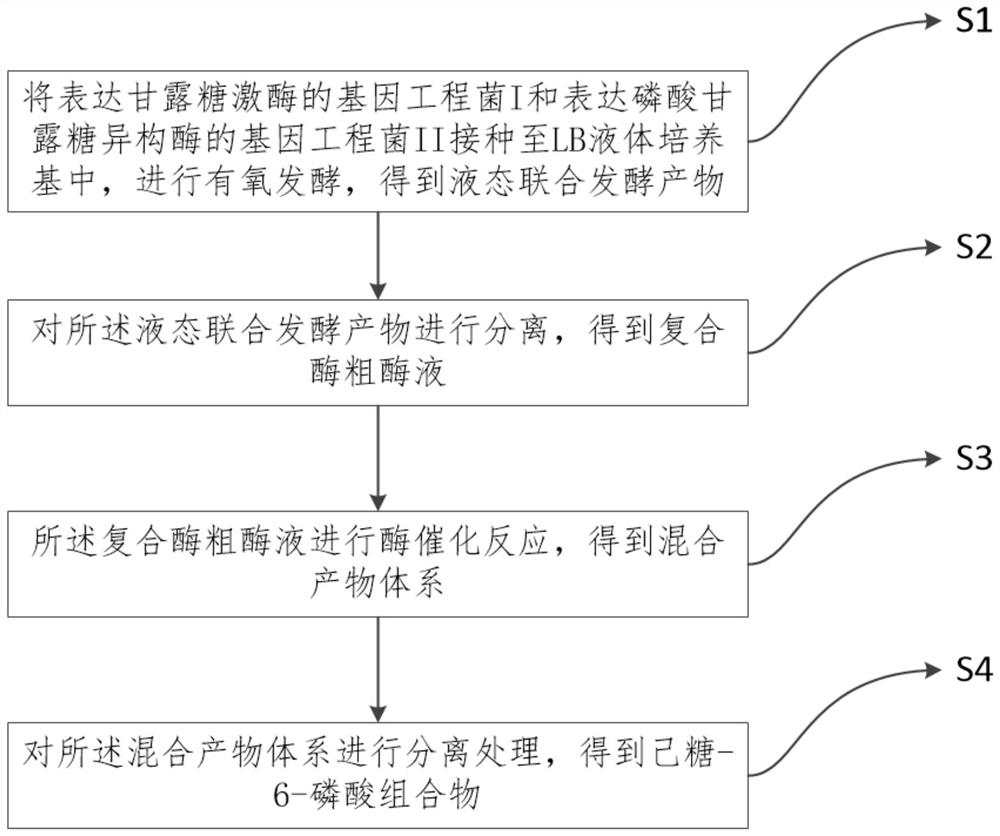

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1: Genetically engineered bacteria I prepare hexokinase crude enzyme liquid by fermentation

[0067] (1) Bacterial fermentation:

[0068] The genetically engineered bacteria I capable of heterologously expressing polyphosphate-dependent mannokinase were inoculated into 50 mL of LB liquid medium (50 mg / L Kana), fermented for 8 h, at a temperature of 37 °C, and at a stirring speed of 180 rpm; The fermentation product was inoculated into 2L of LB liquid medium (50mg / L Kana) according to 1‰, and the air flow was controlled to be 4Nm under the conditions of temperature 30℃ and pH 7 3 / h; after the dissolved oxygen in the fermentation system is stabilized at 10%, an inducer IPTG is added, and the above fermentation conditions are maintained for 12 hours to obtain a fermentation broth.

[0069] (2) Preparation of crude enzyme solution:

[0070] The fermentation broth was centrifuged at 4°C and a rotating speed of 8000rpm to collect the cells, and the cells were re...

Embodiment 2

[0076] Example 2: Preparation of phosphate mannose isomerase crude enzyme liquid by fermentation of genetically engineered bacteria II

[0077] (1) Bacterial fermentation:

[0078] The genetically engineered bacteria II capable of heterologously expressing phosphomannose isomerase was inoculated into 50 mL of LB liquid medium (50 mg / L Kana), and fermented for 8 h at a temperature of 37°C and a stirring speed of 180 rpm; 0.5‰ was inoculated into 2L of LB liquid medium (50mg / L Kana), and the air flow was controlled to be 4Nm under the conditions of temperature of 30℃ and pH of 7 3 / h; after the dissolved oxygen in the fermentation system is stabilized at 10%, an inducer IPTG is added, and the above fermentation conditions are maintained for 12 hours to obtain a fermentation broth.

[0079] (2) Preparation of crude enzyme solution:

[0080] Carry out according to the method described in Example 1.

[0081] (3) Enzyme activity assay:

[0082] Accurately weigh 1mL of the crude ...

Embodiment 3

[0086] Embodiment three: the joint fermentation preparation of mixed enzyme crude enzyme liquid

[0087] (1) Bacterial fermentation:

[0088]The genetically engineered bacteria I capable of heterologously expressing polyphosphate-dependent mannokinase was inoculated into 50 mL of LB liquid culture medium (50 mg / L Kana); at the same time, the heterologous expression of mannose phosphate isomer The genetically engineered bacteria II of the enzyme was inoculated into 50 mL of LB liquid medium (50 mg / L Kana); the fermentation conditions of both were 37 ° C, 8 h, and 180 rpm; and then the fermentation products of the genetically engineered bacteria I were 1‰, gene The fermentation product of engineering bacteria II was inoculated into 2L of LB liquid medium (50mg / L Kana) according to 0.5‰, and the air flow was controlled to be 4Nm under the conditions of temperature of 30℃ and pH of 7 3 / h; after the dissolved oxygen in the fermentation system is stabilized at 10%, an inducer IPTG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com