Thermosetting inkjet ink and printing method

A heat-curable, ink-jet technology, applied in copying/marking methods, inks, printing, etc., can solve problems such as insufficient film interface adhesion, and achieve excellent substrate adhesion, good surface adhesion, and high surface hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

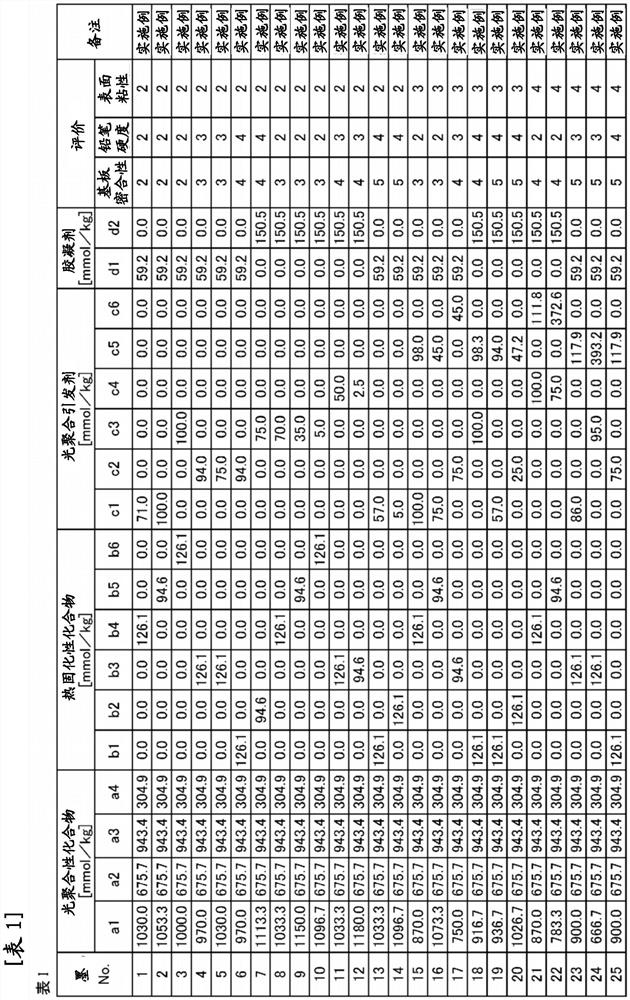

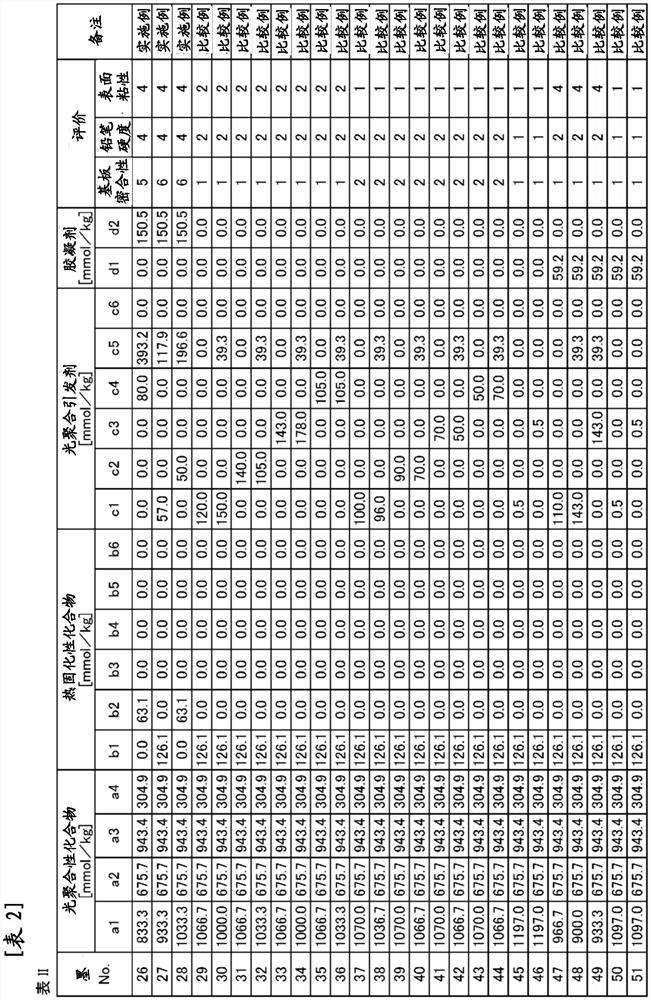

Examples

Embodiment 1

[0206]

[0207] The following dispersing agent 1, dispersing agent 2 and dispersion medium were put into a stainless steel beaker, heated and stirred on a hot plate at 65°C for 1 hour to dissolve, and after cooling to room temperature, the following pigment was added to it, and the Put 200g of 0.5mm zirconia beads into a glass bottle and plug it with a stopper. The zirconia beads were removed after dispersing with a paint shaker until the particle size became a desired particle size.

[0208]Dispersant 1: 5.6 parts by mass of EFKA7701 (manufactured by BASF)

[0209] Dispersant 2: Solsperse 22000 (manufactured by ルーブリゾール, Japan)

[0210] 0.4 parts by mass

[0211] Dispersion medium: Dipropylene glycol diacrylate (containing 0.2% UV-10)

[0212] 80.6 parts by mass

[0213] Pigment: PY185 (manufactured by BASF Co., Ltd., パリオトールイエローD1155)

[0214] 13.4 parts by mass

[0215]

[0216] In the preparation of the above-mentioned yellow pigment dispersion, the dispersant, the...

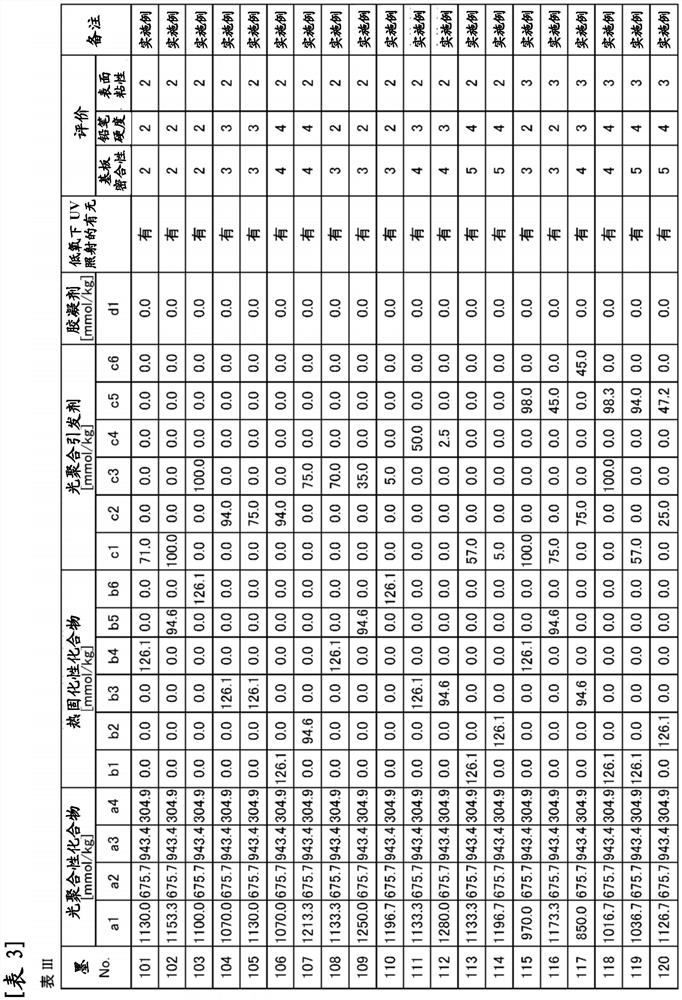

Embodiment 2

[0290]

[0291] In addition to 3.0 g of the yellow pigment dispersion and 1.0 g of the cyan pigment dispersion, ink compositions described in Tables III to V below were added to prepare inkjet inks, which were filtered through a Teflon 3 μm membrane filter manufactured by ADVATEC.

[0292]

[0293] Each of the prepared inkjet inks was loaded into an inkjet recording apparatus having an inkjet recording head provided with piezoelectric type inkjet nozzles. Using this apparatus, patterning was performed on a copper-clad laminate for a printed wiring board (FR-4 thickness 1.6 mm, size 150 mm×95 mm).

[0294] The ink supply system consists of an ink tank, an ink flow path, a sub-tank in front of the inkjet recording head, a pipe with a metal filter, and a piezoelectric head. From the ink tank to the head section, the ink is heated to 90°C. A heater is also built into the piezoelectric head, and the temperature of the ink in the recording head is heated to 90°C. As for the pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com