Method for preparing functional porous hydrogel based on liquid-gas-liquid drop reactor

A porous hydrogel, functional technology, used in chemical instruments and methods, other chemical processes, alkali metal compounds, etc. Use of active agent, high adsorption capacity, effect of enhancing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

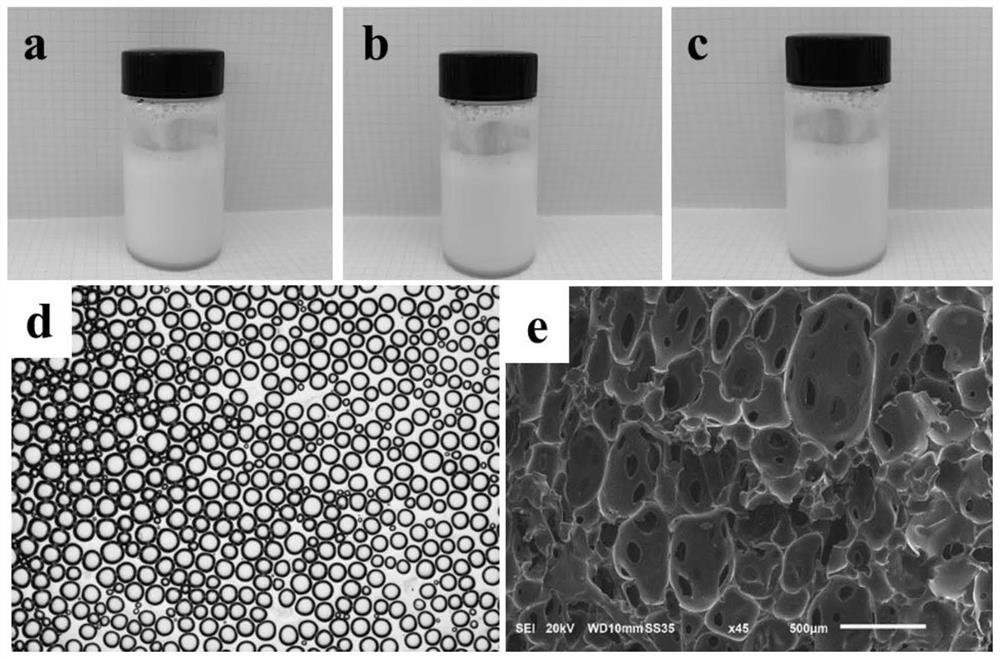

Method used

Image

Examples

Embodiment 1

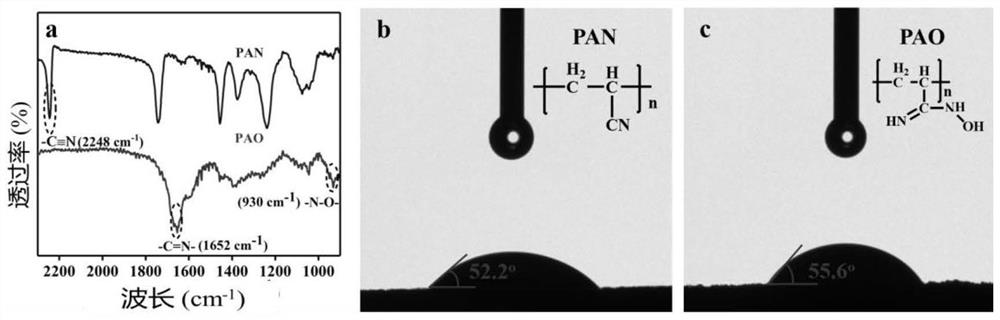

[0034] (1) the preparation of polypropylene amidoxime;

[0035] In a flask, put 60 mmol of NH 2 OH·HCl was added to 45 mL of N,N-methyleneformamide at 45°C, heated in a water bath for 30 min, and then 27 mmol Na was added under vigorous stirring. 2 CO 3 and 18mmol NaOH, and then the resulting mixed solution was reacted under mechanical stirring at 1000rpm for 3.0h; then 60mmol of PAN was added, and after complete dissolution, the temperature was raised to 65°C and the reaction was continued for 24h; 13.5mmol of Na was added again 2 CO 3 and 9.0 mmol of NaOH, after continuing to react for 24 hours, the supernatant was collected by centrifugation at 13,000 rpm until no precipitation occurred, the supernatant was dropped into pure water to collect the flocs produced, and freeze-dried to obtain polypropylene Amidoxime products (PAO);

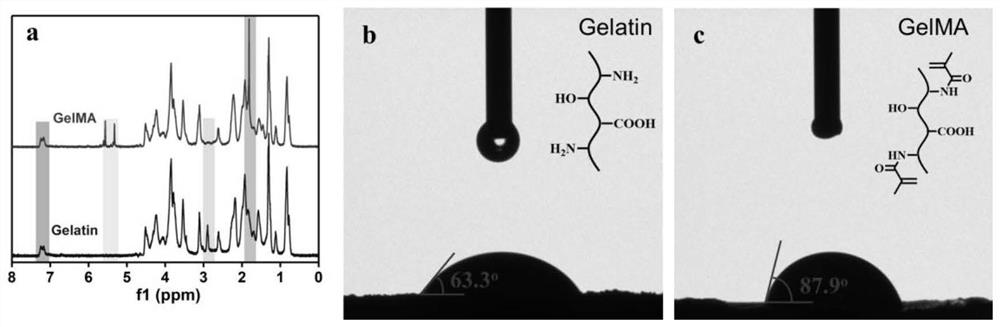

[0036] (2) preparation of methacryloyl gelatin;

[0037] Add 5.0g of Gelatin to 50mL, 2.0M, pH 7.4 phosphate buffer solution, heat up to 50°C ...

Embodiment 2

[0046] (1) the preparation of polypropylene amidoxime;

[0047] In a flask, put 50 mmol of NH 2 OH·HCl was added to 35 mL of N,N-methyleneformamide at 30°C, heated in a water bath for 20 min, and then 20 mmol Na was added under vigorous stirring. 2 CO 3 and 10 mmol NaOH, and then the resulting mixed solution was reacted under mechanical stirring at 800 rpm for 2.0 h; then 50 mmol of PAN was added, and after complete dissolution, the temperature was increased to 60 °C and the reaction was continued for 12 h; 15 mmol of Na was added again. 2 CO 3 and 10mmol of NaOH, after continuing to react for 12h, the supernatant was collected by centrifugation at 10,000rpm until no precipitation was produced, the supernatant was dropped into pure water to collect the flocs produced, and freeze-dried to obtain the polypropylene amine Oxime products (PAO);

[0048] (2) preparation of methacryloyl gelatin;

[0049] Add 4.0 g of Gelatin to 40 mL, 1.0 M, pH 7.0 phosphoric acid buffer solutio...

Embodiment 3

[0054] (1) the preparation of polypropylene amidoxime;

[0055] In a flask, put 70 mmol of NH 2 OH·HCl was added to 55 mL of N,N-methyleneformamide at 55°C, heated in a water bath for 40 min, and then 30 mmol Na was added under vigorous stirring. 2 CO 3 and 25mmol NaOH, and then the resulting mixed solution was reacted under mechanical stirring at 1200rpm for 4.0h; then 70mmol of PAN was added, and after complete dissolution, the temperature was raised to 85°C and the reaction was continued for 36h; 15mmol of Na was added again 2 CO 3 and 15mmol of NaOH, after continuing to react for 36h, the supernatant was collected by centrifugation at 15000rpm until no precipitation was produced, the supernatant was dropped into pure water to collect the flocs produced, and freeze-dried to obtain the polypropylene amine. Oxime products (PAO);

[0056] (2) preparation of methacryloyl gelatin;

[0057] Add 6.0g of Gelatin to 60mL, 3.0M, pH 8.0 phosphate buffer solution, heat up to 60°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com