Preparation method of spherical sludge-based solid acid catalyst as well as product and application of spherical sludge-based solid acid catalyst

A solid acid catalyst and sludge technology, which is applied in the field of solid waste recycling, can solve problems such as undiscovered and secondary pollution, and achieve the effects of improving modification effect, easy recovery and reducing pollutant discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

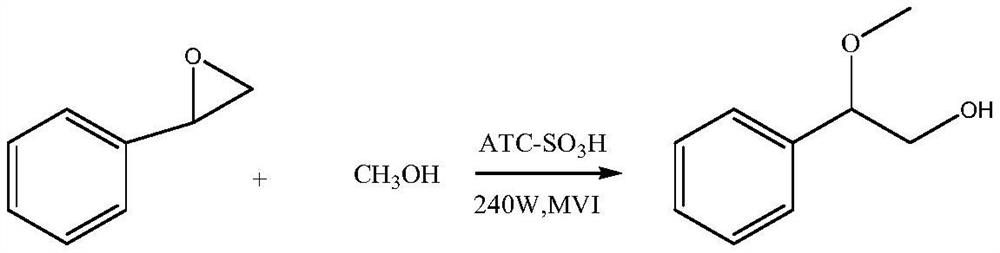

Method used

Image

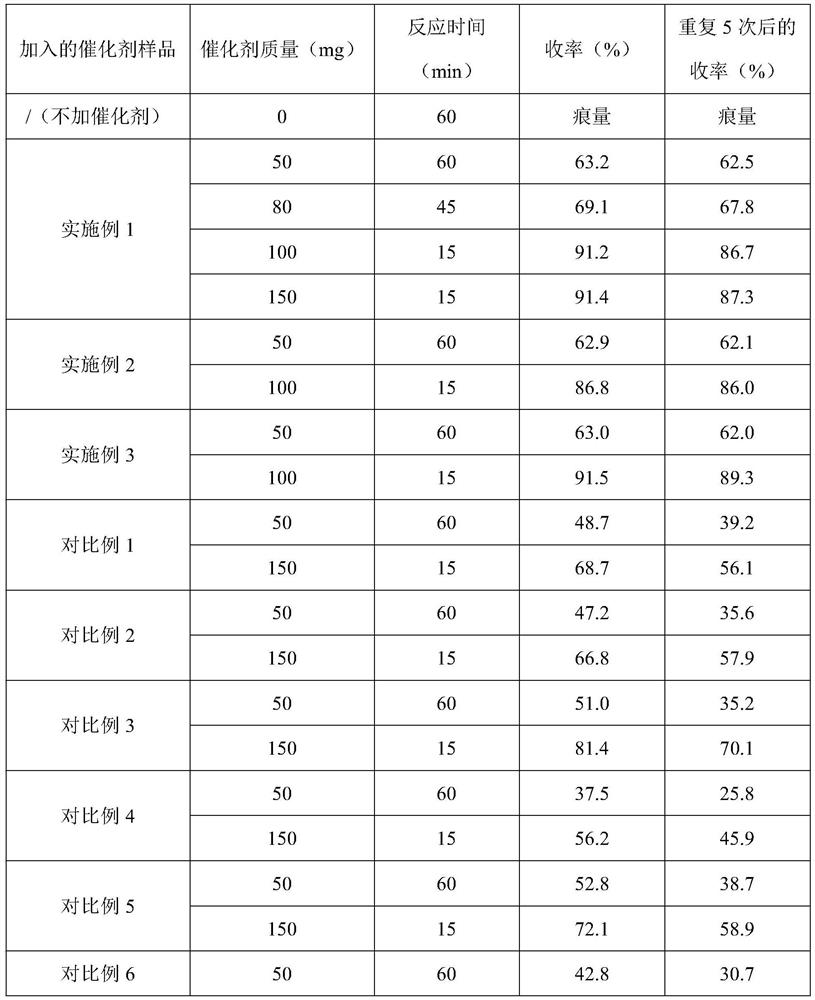

Examples

Embodiment 1

[0030] The preparation of spherical sludge-based solid acid catalyst includes the following steps:

[0031] (1) First, add 10.0 g of air-dried chemical sludge to 60.0 mL of 5.5 mol / L hydrochloric acid and soak it for 10 hours; then filter it, wash it with deionized water until it becomes neutral, dry it and place it in a nitrogen atmosphere at 500 °C for preheating. Carbonized for 2h; then take 5.0g of the above-obtained solid and add it to 35.0mL of 6mol / L NaOH solution and soak it for 36h, filter, wash, dry, and finally put the obtained solid in a nitrogen atmosphere at 750 °C for high-temperature carbonization for 2h to obtain activated carbon .

[0032] (2) Preparation of acidified attapulgite: add 15.0 g of 150 mesh natural attapulgite to 50.0 ml of 8 mol / L hydrochloric acid; place the mixture in a constant temperature shaker and shake at 80°C for 2 hours; separate the solid by centrifugation and wash with deionized water The filtrate was neutral, and finally the obtaine...

Embodiment 2

[0037] The preparation of spherical sludge-based solid acid catalyst includes the following steps:

[0038] (1) First, 10.0g of air-dried chemical sludge was added to 25.0mL of 5mol / L hydrochloric acid and soaked for 14h; then filtered, washed with deionized water until neutral, dried and placed in a nitrogen atmosphere at 450°C for pre-carbonization 2.5h; then take 5.0g of the solid obtained above and add it to 35.0mL of 6mol / L NaOH solution for immersion for 24h, filter, wash, dry, and finally put the obtained solid in a nitrogen atmosphere at 700 ℃ high temperature carbonization for 2.5h, that is, Activated carbon.

[0039](2) Preparation of acidified attapulgite: add 10.0 g of 150 mesh natural attapulgite to 50.0 ml of 8 mol / L hydrochloric acid; place the mixture in a constant temperature shaker and shake at 60°C for 2 hours; separate the solid by centrifugation and wash with deionized water Until the filtrate is neutral, finally, the obtained sample is dried at 110° C. f...

Embodiment 3

[0044] The preparation of spherical sludge-based solid acid catalyst includes the following steps:

[0045] (1) First, 10.0g of air-dried chemical sludge was added to 25.0mL of 6mol / L nitric acid and soaked for 18h; then filtered, washed with deionized water until neutral, dried and placed in a nitrogen atmosphere at 400°C for pre-carbonization 2.5h; then take 5.0g of the above-obtained solid and add it to 35.0mL of 7mol / L NaOH solution for immersion for 24h, filter, wash, dry, and finally put the obtained solid in a nitrogen atmosphere at 800 °C for high temperature carbonization for 2.5h, that is, Activated carbon.

[0046] (2) Preparation of acidified attapulgite: add 12.0 g of 150 mesh natural attapulgite to 50.0 ml of 8 mol / L hydrochloric acid; place the mixture in a constant temperature shaker and shake at 60°C for 2 hours; separate the solid by centrifugation and wash with deionized water Until the filtrate is neutral, finally, the obtained sample is dried at 110° C. f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com