Preparation and application of hollow hierarchical heterostructure three-component sulfide photoelectric material

A technology of heterostructures and optoelectronic materials, applied in the fields of luminescent materials, cadmium sulfide, chemical instruments and methods, etc., can solve the problems of under-researched, complex synthesis steps, lengthy nanomaterials, etc. Absorption efficiency, effect of matching band structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

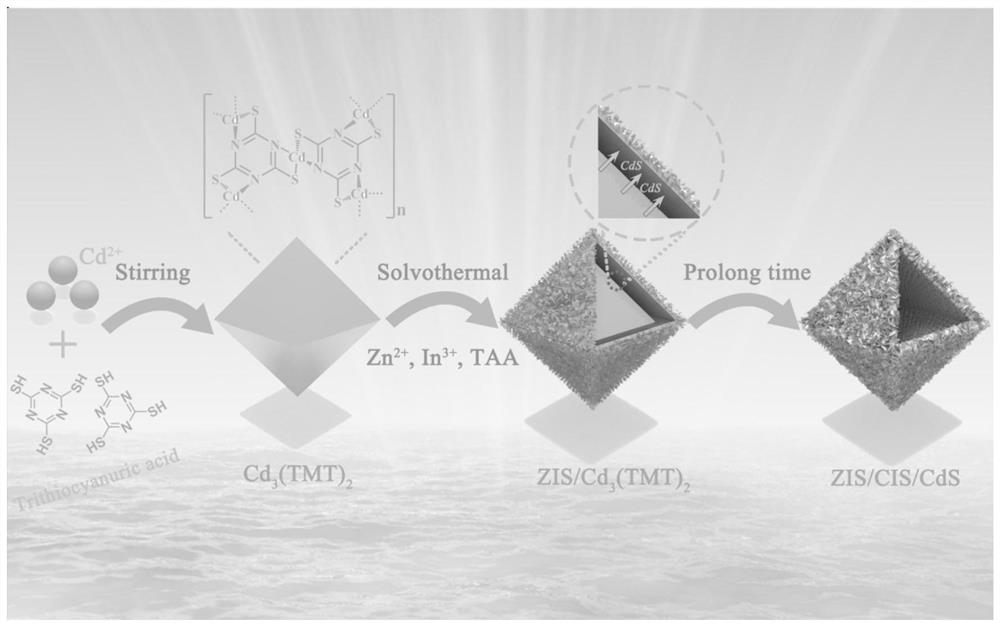

[0052] A three-component ZnIn with hollow hierarchical heterostructure 2 S 4 / CnIn 2 S 4 / CdS material preparation, such as figure 1 It mainly includes the following steps:

[0053] (1) Preparation of Cd 3 (C 3 N 3 S 3 ) 2 ;

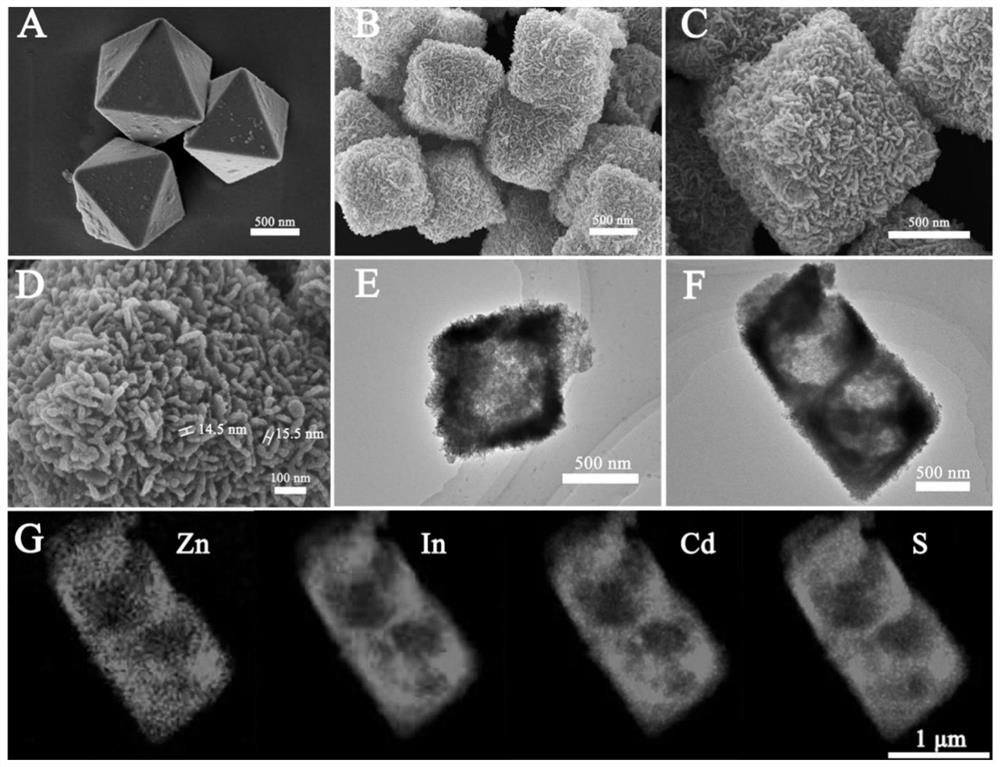

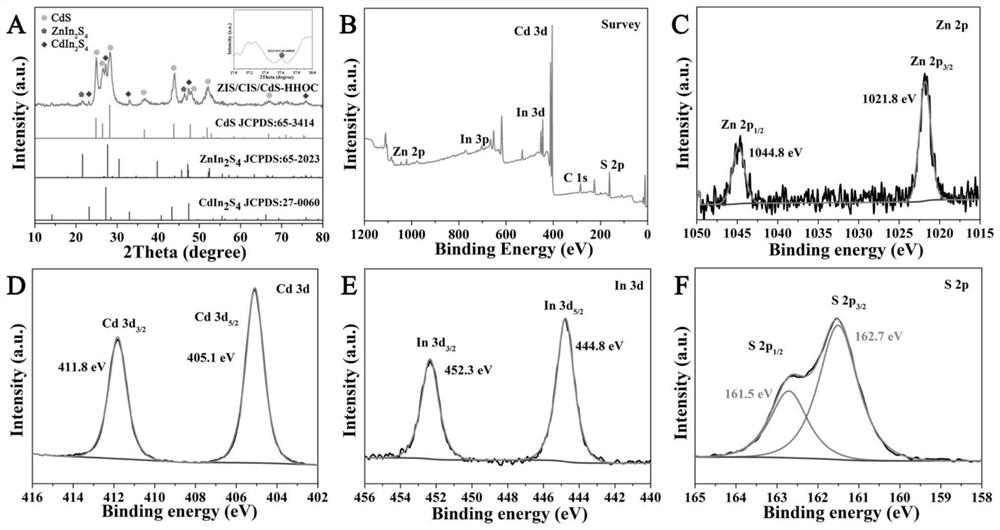

[0054] Preparation of Cd by stirring at room temperature 3 (C 3 N 3 S 3 ) 2 Octahedron, mainly including: Weigh 2.7498g of CdCl 2 Dissolve in 100mL ultrapure aqueous solution and stir to form transparent solution A, then weigh 1.7727g of thiocyanate and dissolve it in 100mL 0.015M NaOH solution to form solution B; under strong stirring, add solution B dropwise to A Then keep vigorous stirring for 5 minutes, and react under slow stirring at room temperature for 12 hours; after the reaction is over, centrifugal washing, the obtained white product is washed with ethanol and collected by centrifugation (three cycles), and finally it is placed at 60 ° C. 12 hours in a vacuum oven. Scanning Electron Microscope (SEM) to observe the synthesized ...

Embodiment 2

[0058] Based on three-component ZnIn with hollow hierarchical heterostructure 2 S 4 / CnIn 2 S 4 / CdS photoelectrochemical sensor

[0059] (1) Cleaning of ITO electrode and preparation of modified electrode

[0060] Preparation of ZIS / CIS / CdS-HHOC / ITO electrodes: ITO conductive substrate (3.0 × 1.0 cm 2 ) was placed in a 1M NaOH (Vwater:Vacetone=1:1) solution for sonication for 30 min, then washed three times with absolute ethanol and ultrapure water, and then placed in a 65°C oven to dry for 45 min. Store the cleaned ITO conductive substrate in a cool and dark place. Weigh 3 mg of the prepared ZIS / CIS / CdS-HHOC powder into 1 mL of ultrapure water, and stir to mix for 6 hours. Take 10 μL to the concentration of 3 mg·mL -1 The above suspension is added dropwise on the pretreated ITO conductive glass, and the active area is 0.0961cm 2 , placed in an oven at 60 °C for 12 h, and cooled to room temperature to obtain a stable ZIS / CIS / CdS-HHOC / ITO electrode.

[0061] (2) Prepa...

Embodiment 3

[0067] Three-component ZnIn with hollow hierarchical heterostructure prepared in Example 1 2 S 4 / CnIn 2 S 4 Application of / CdS materials in photocatalytic hydrogen production.

[0068] The catalyst performance was tested by using the photocatalytic reaction system and gas chromatography of Zhongjiao Jinyuan. 50 mg of the ZIS / CIS / CdS-HHOC material prepared in Example 1 was dispersed in a solution containing 90vt% deionized water and 10vt% lactic acid. The photocatalytic reaction was carried out in a 250 mL airtight reaction. Before the reaction, nitrogen gas was introduced for 30 min to remove excess air in the system. A 300W Xe lamp was used as the light source, and a 420nm cut-off filter was installed to filter out the ultraviolet light in the light source. During the reaction, the suspension was continuously stirred and thoroughly exposed to light. In addition, the reaction temperature was controlled around 25°C by external condensing water. During the reaction, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com