Method for improving thermal coagulation performance of vegetable protein

A vegetable protein and thermal coagulation technology, which is applied in the field of vegetable protein processing, can solve the problem of lack of heat coagulation of egg white protein in soybean protein, and achieve the effects of avoiding secondary processing, low energy consumption and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

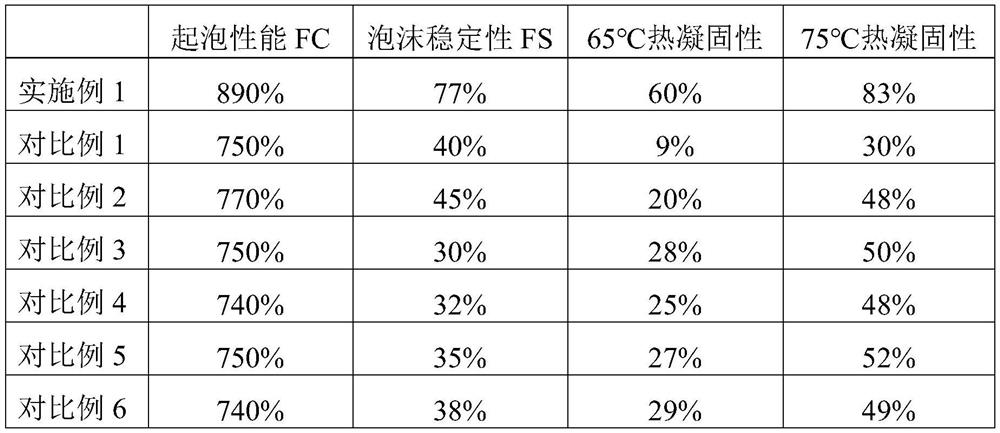

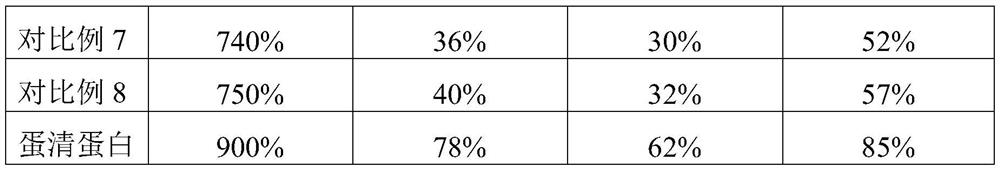

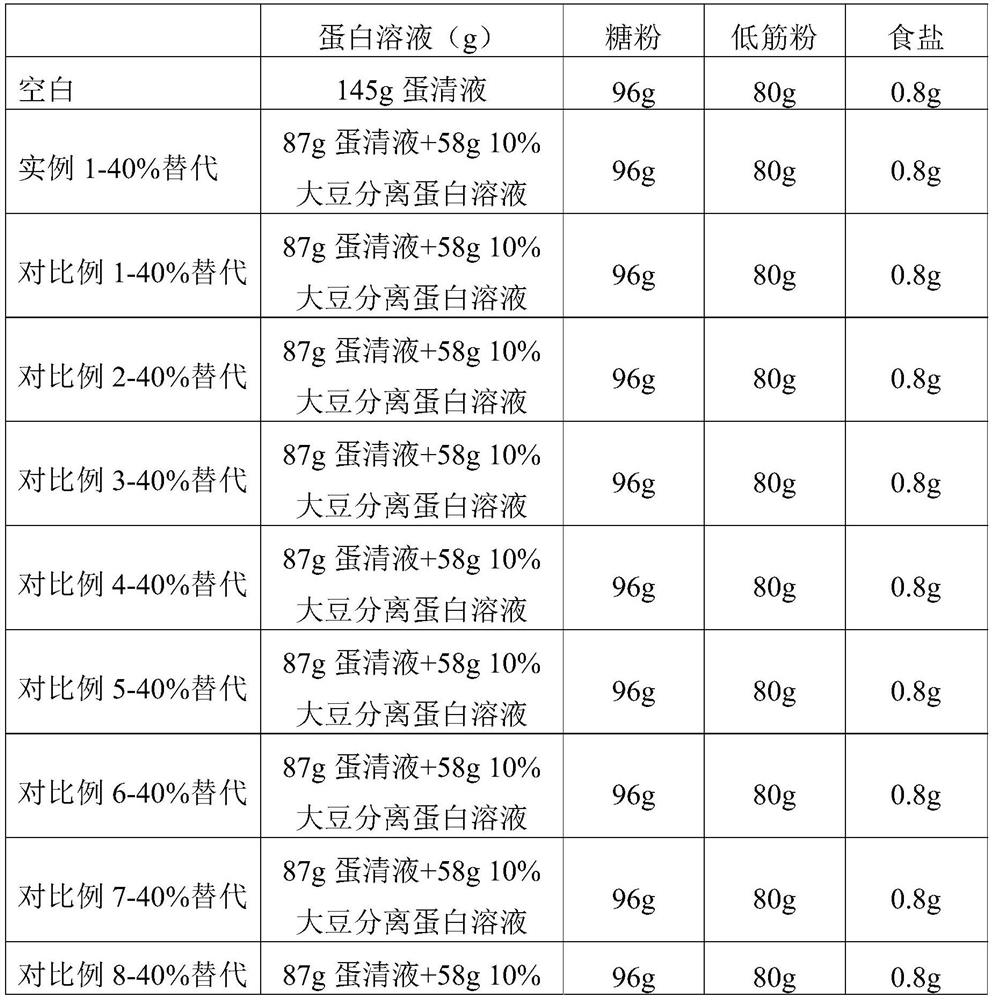

Examples

preparation example Construction

[0074] Preparation of initial protein solution

[0075] The protein solution provided by the present invention may be an aqueous solution of any conventional commercially available protein, or may be a protein-containing solution obtained by extracting a protein-containing plant material. According to one embodiment of the present invention, the protein solution of the present invention is obtained by extracting protein-containing plant material. Preferably, the protein solution of the present invention is obtained by extracting soybean meal.

[0076] Soybean meal is a by-product of soybean oil extraction. Also known as "soybean meal", soybean meal obtained after soybean oil degreasing operation is also called "defatted soybean meal", which usually contains 40-55% by weight of protein. In particular embodiments of the present invention, "defatted soybean meal" is used.

[0077] According to one embodiment of the present invention, the weight ratio of defatted soybean meal ...

Embodiment 1

[0116] Weigh 200g of low-temperature defatted soybean meal, stir and disperse in 1400g of warm water at 50°C, adjust the pH to 9, stir for 60min, and then centrifuge at 3000g for 10min to obtain a supernatant; add 0.008 wt‰ gluconic acid-δ-into the supernatant. Esters (based on dry matter weight of solution), heated at 100°C for 60 min; adjusted pH to 5.0, heated at 70°C for 30 min; added 0.08 wt% transglutaminase (based on solution dry matter weight) , heated at 40°C for 120 min; adjusted pH to 4.5 with 1N HCl solution, centrifuged to obtain curd precipitation; 10 times the mass of deionized water was used to disperse and dissolve the curd precipitation, and 10% concentration of NaOH solution was used to adjust pH to 7.5, then shear and disperse with a shearing machine at 6000 rpm for 3 minutes; add 0.2% neutral protease Thermoase GL30 (based on dry precipitation quality), and react at 50 ° C for 30 minutes; finally, sterilize in a boiling water bath for 5 minutes, and carry o...

Embodiment 2

[0146] Weigh 200g of low-temperature defatted soybean meal, stir and disperse in 1400g of warm water at 50°C, adjust the pH to 9, stir for 60min, and then centrifuge at 3000g for 10min to obtain a supernatant; add 0.08 wt‰ gluconic acid-δ- to the supernatant Lactone (based on dry matter weight of solution), heated at 120°C for 30 min; adjusted pH to 6.0, heated at 90°C for 10 min; added 2.4% transglutaminase (based on dry matter weight of solution) , heated at 60 °C for 30 min; adjusted pH to 4.5 with 1N HCl solution, centrifuged to obtain curd precipitation; 8 times the mass of deionized water was used to disperse and dissolve the curd precipitation, and 10% concentration of NaOH solution was used to adjust pH to 8, then shear and disperse with a shearing machine at 8000rpm for 3min; add 0.01% papain (based on dry basis precipitation quality), react at 40°C for 60min; finally 120°C high temperature steam sterilization for 20s, and spray-drying ( The inlet temperature is 185°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| foam stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com