Preparation method of ionic hypercrosslinked porous organic polymer supported cobalt catalyst

A technology of ultra-high cross-linking and cobalt catalysts, which is applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, organic chemistry, etc., and can solve problems such as increased energy consumption and excessive emissions of production costs. Achieve the effects of improving adsorption capacity, enhancing interaction, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Provided in the present invention is a preparation method of an ionic ultra-highly cross-linked porous organic polymer-supported cobalt catalyst, specifically the preparation method comprises:

[0030] S1. Under nitrogen protection, tetraphenylporphyrin, dibromo-p-xylene and N-methylimidazole were dissolved in 1,2-dichloroethane solvent to obtain a mixed solution A;

[0031] Adding aluminum chloride to the mixed solution A, followed by stirring in an oil bath, quenching, rinsing, purification and drying to obtain the intermediate product B;

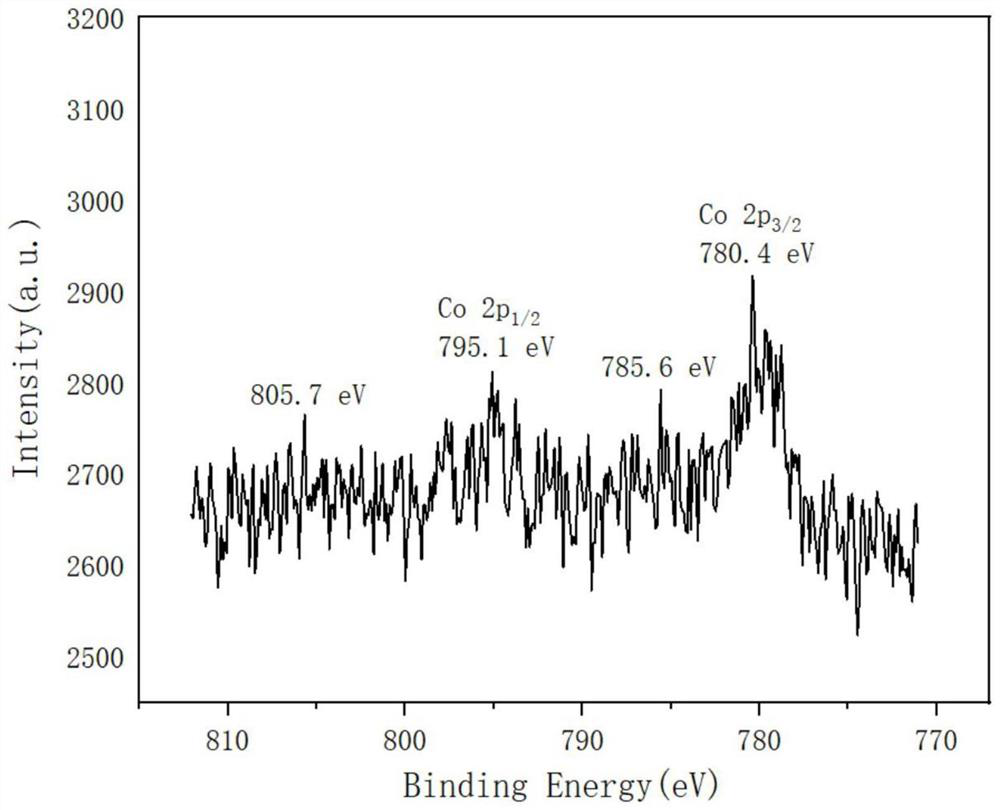

[0032] S2. Dissolving cobalt acetate in deionized water to obtain solution C;

[0033] Add an acetonitrile solution containing the intermediate product B to the solution C, then stir at room temperature, centrifuge, wash and dry to obtain the target product D; the target product D is an ionic ultra-highly cross-linked porous organic polymer loaded with a cobalt catalyst.

Embodiment S1

[0034] Preferably, for the steps disclosed in the above-mentioned preparation method, the following example S1. Preparation of intermediate product B is provided in the present invention

[0035] Under nitrogen protection, 307.5 mg tetraphenylporphyrin, 316.8 mg dibromo-p-xylene and 39.6 μL N-methylimidazole were dissolved in 10 mL of 1,2-dichloroethane solvent to obtain a mixed solution A ;Add 1.30g of aluminum chloride to the mixture A, then heat the oil bath to 80°C and keep stirring for 24h;

[0036] Use HCl and H at a volume ratio of 2:1 2 The above reaction system was quenched with a mixture of O, then washed three times with deionized water and twice with absolute ethanol, and further purified by extracting with absolute ethanol for 48 hours, and finally dried in a vacuum oven at 65°C for 24 hours to obtain intermediate product B.

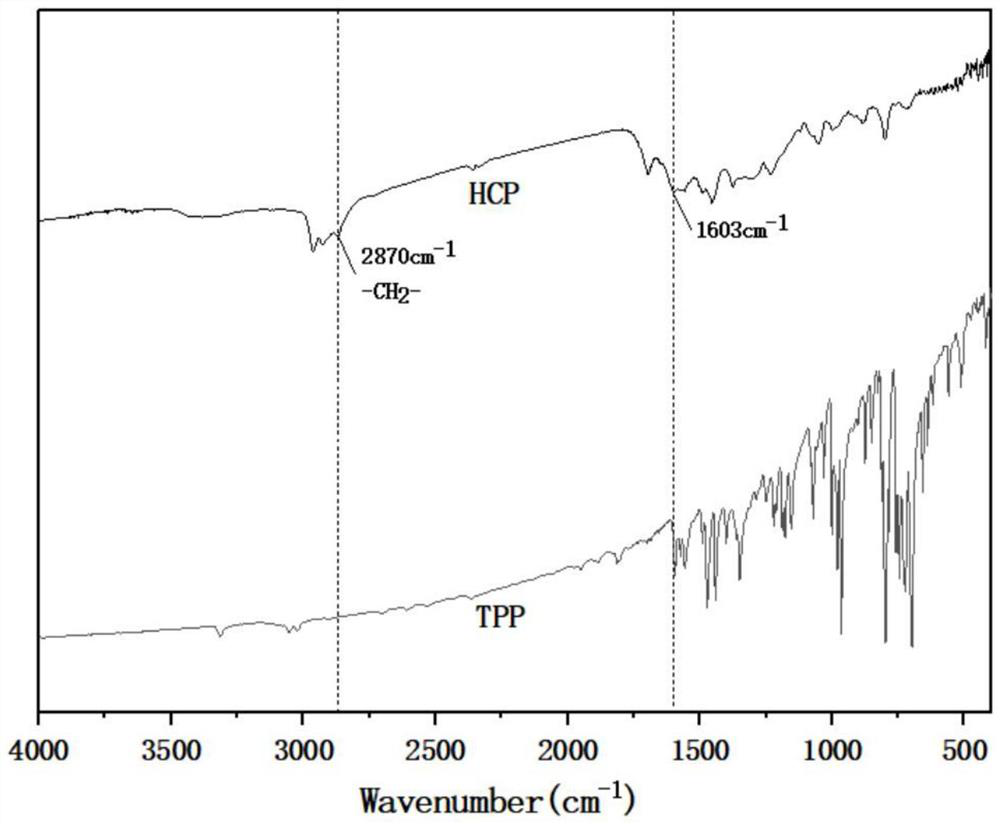

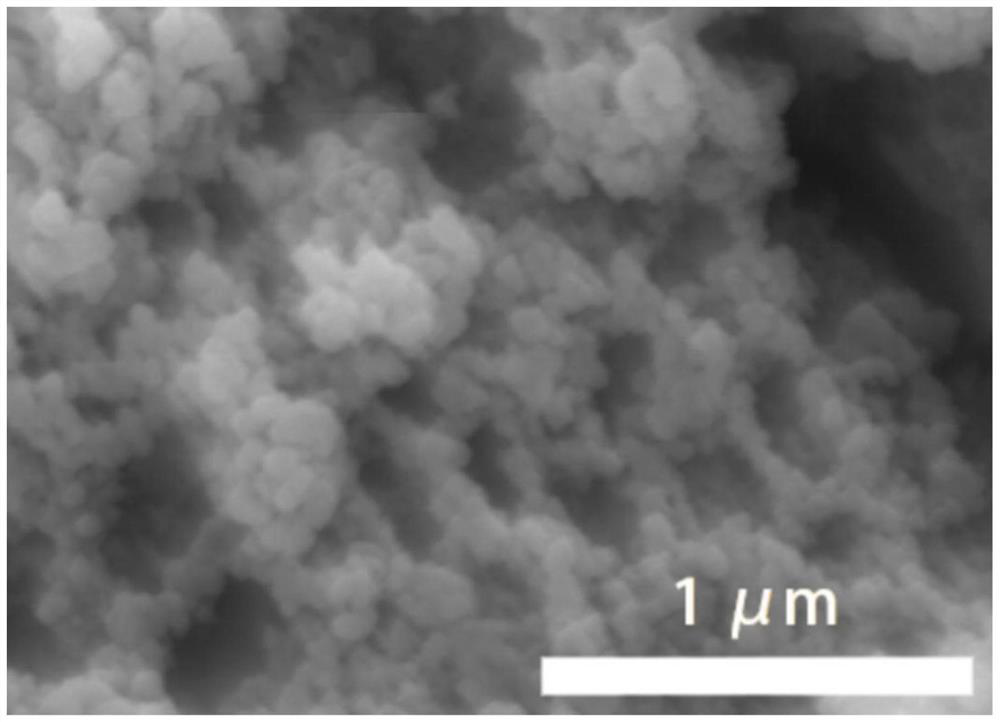

[0037] In the above step S1, the yield of the intermediate product B is 98%, and the prepared intermediate product B is an ultra-highly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com