Heterojunction nano array electrode material and preparation method and application thereof

A nano-array and electrode material technology, applied in the direction of electrodes, electrolytic components, electrolytic process, etc., can solve the problems of limited activity and achieve the effects of rapid response, accelerated charge transport, and effective electronic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 δ-MnO 2 / FeOOH heterojunction nanoarray electrodes

[0044] The δ-MnO 2 The preparation method of FeOOH heterojunction nano-array electrode comprises the following steps:

[0045] S1, 0.158g (1mmol) potassium permanganate (KMnO 4 ) was dissolved in 30mL of deionized water, fully stirred on a magnetic stirrer for 0.5h (the stirrer speed was 300r / min) to obtain a uniform mixed solution;

[0046] S2. Transfer the mixed solution obtained in step S1 to a polytetrafluoroethylene high-pressure reaction kettle, put a piece of cleaned iron net, seal it and place it in a blast drying oven for hydrothermal reaction, react at 130°C for 7h, and react After the end, let it cool naturally, wash it with N,N-dimethylformamide for 3 times, and dry it at 70°C for 2 hours to obtain δ-MnO on the iron grid. 2 / FeOOH heterojunction nanoarray electrodes.

[0047] Material Characterization:

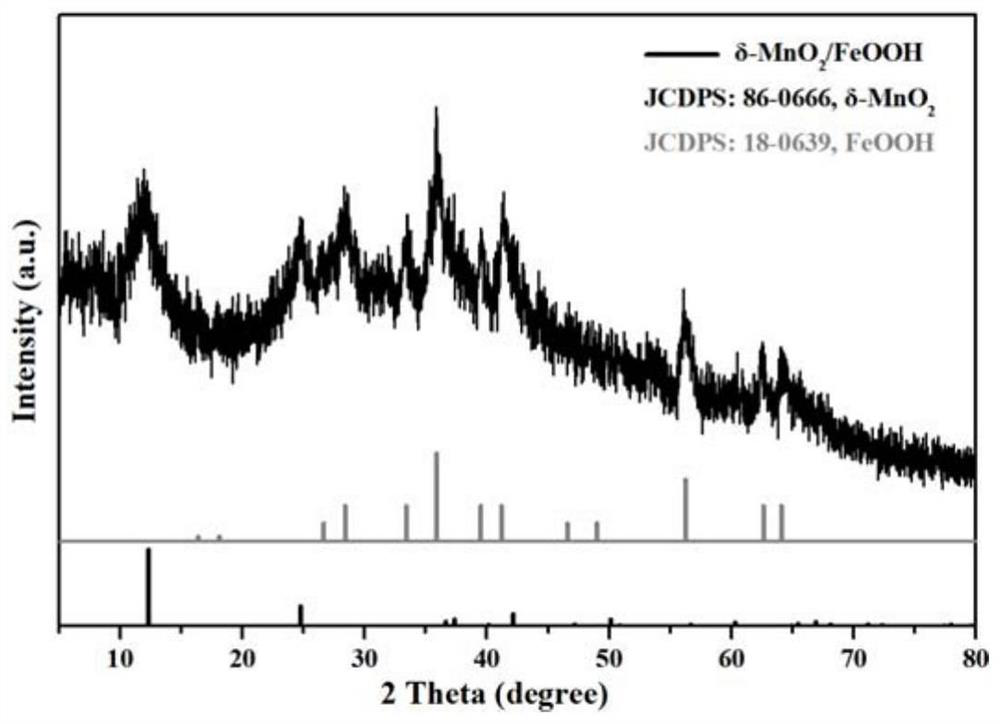

[0048] The product was identified by X-ray powder diffractometer, and its crystal phase...

Embodiment 2

[0049] Example 2δ-MnO 2 / Ni-FeOOH heterojunction nanoarray electrode

[0050] The δ-MnO 2 The preparation method of Ni-FeOOH heterojunction nano-array electrode comprises the following steps:

[0051] S1, 1.783g (7.5mmol) nickel chloride (NiCl 2 ·6H 2 O) and 11.852g (75mmol) potassium permanganate (KMnO 4 ) was dissolved in 150mL of deionized water, fully stirred on a magnetic stirrer for 3h (the stirrer speed was 500r / min) to obtain a uniform mixed solution;

[0052] S2. Transfer the mixed solution obtained in step S1 to a polytetrafluoroethylene high-pressure reaction kettle, put a piece of washed foam iron, seal it and place it in a blast drying oven for hydrothermal reaction, react at 180°C for 3h, and react After the end, let it cool down naturally, wash with ethanol for 3 times, and dry at 60°C for 6 hours to obtain δ-MnO grown on foam iron 2 / Ni-FeOOH heterojunction nanoarray electrodes.

[0053] Material Characterization:

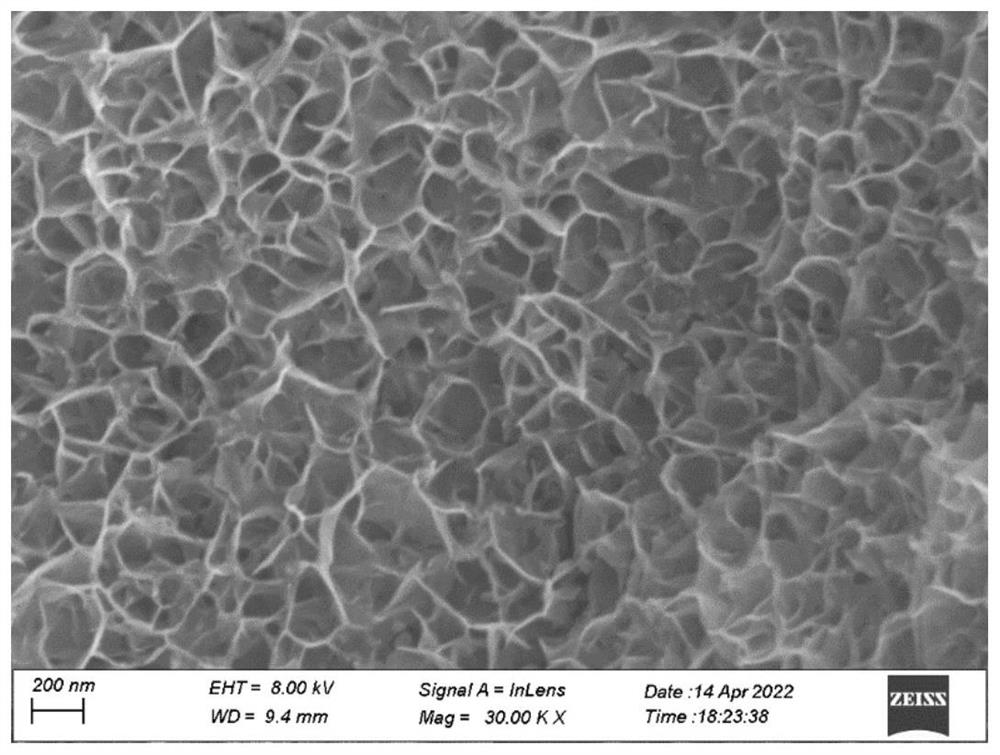

[0054] The morphology of the obtained...

Embodiment 3

[0055] Example 3δ-MnO 2 / Zn-FeOOH heterojunction nano-array electrode

[0056] The δ-MnO 2 The preparation method of Zn-FeOOH heterojunction nano-array electrode comprises the following steps:

[0057] S1, 2.195g (10mmol) zinc acetate (Zn(CH 3 COO) 2 2H 2 O) and 7.901g (50mmol) potassium permanganate (KMnO 4 ) was dissolved in 500mL of deionized water, fully stirred on a magnetic stirrer for 3h (the stirrer speed was 650r / min) to obtain a uniform mixed solution;

[0058] S2. Transfer the mixed solution obtained in step S1 to a polytetrafluoroethylene high-pressure reaction kettle, put several clean iron wires, seal it and place it in a blast drying oven for hydrothermal reaction, and react at 150° C. for 4 hours. After the reaction, let it cool down naturally, wash with methanol for 3 times, and dry at 50°C for 3 hours to obtain δ-MnO that grows on the iron wire. 2 / Zn-FeOOH heterojunction nanoarray electrodes.

[0059] Material Characterization:

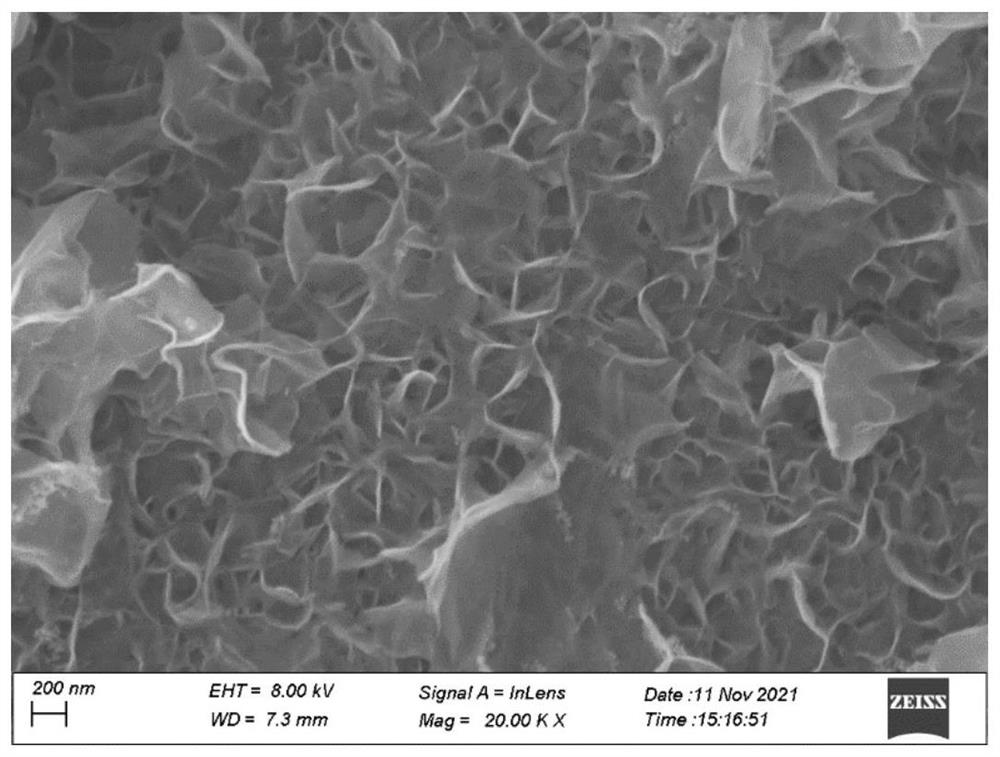

[0060] The morpholo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com