Large board of square cabin and square cabin

A press plate and alloy plate technology, applied in the shelter field, can solve the problems of reducing the thickness of the intermediate foam insulation layer, complex manufacturing process, and high cost, and achieve the effect of reducing the weight of the splint, making the material firm, and reducing the surface density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Selection and optimization of the adhesive used in the aramid press plate.

[0044] Since the aramid fiber pressing cloth needs to be further pressed and formed, the adhesive required to be used first has the characteristics of hot pressing reaction. In addition, it should have a certain viscosity at room temperature (viscosity range is 80-200mPa.s), and the initial viscosity of the adhesive It directly affects the appearance of the aramid press cloth. According to literature research and small-scale simulation test, four kinds of adhesives were selected from more than ten kinds of adhesives for further comparison test of woven aramid press cloth. The comparison results are shown in Table 1.

[0045] Table 1 Influence of different adhesives on the appearance of aramid laminate

[0046]

[0047] From the analysis of the comparison results in Table 1, it can be seen that in the weaving process of acrylic and epoxy resin adhesives, due to the strong binding ...

Embodiment 2

[0048] Example 2: Selection and optimization of crosslinking agent in non-woven fabrics.

[0049] Due to trimethylolpropane-tris(3-aziridine) propionate, the three aziridine groups are very active and can be cross-linked with the hydroxyl groups in the acrylate adhesive at high density, and under high temperature and high pressure, nitrogen The propidyl group can also undergo a cross-linking reaction with the carbonyl group in the ester group, so that the formed non-woven fabric composite material has excellent heat resistance, weather resistance, light resistance, corrosion resistance, etc., and can also improve the formation of composite materials. bond strength and improve material flexibility. In this example, the addition of aziridine crosslinking agent is mainly to improve the interface between resin and fiber surface, and the interface is mainly composed of surface atoms and surface subatoms. The composition of matrix and fiber surface atoms depends on the affinity betw...

Embodiment 3

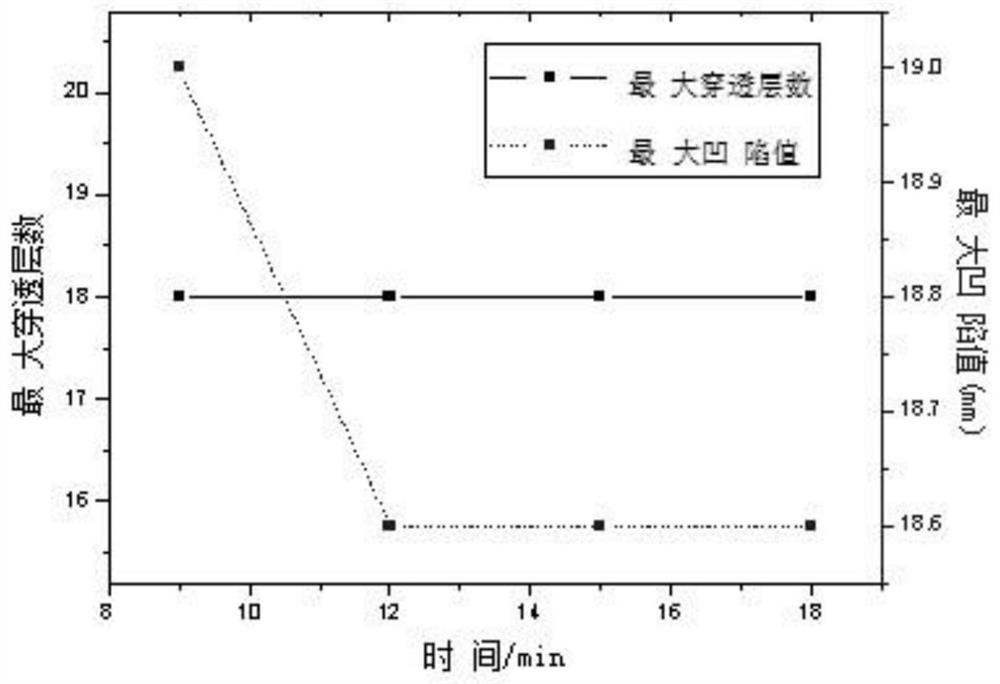

[0053] Embodiment 3: Optimization of the hot pressing process of aramid fiber pressing plate.

[0054] According to the performance parameters of the selected adhesive, the tentative hot-pressing temperature is 140°C (according to the empirical value, the hot-pressing temperature is preferably 20-50°C higher than the activation temperature of the adhesive), and the hot-pressing time is 15min (according to the fact that no gas is released during hot-pressing) phenomenon), the hot pressing pressure is 10MPa (depending on the pressure of similar products), and the performance results of the prepared aramid pressing plate material are shown in Table 3.

[0055] Table 3 Comparison results of aramid materials and traditional materials

[0056]

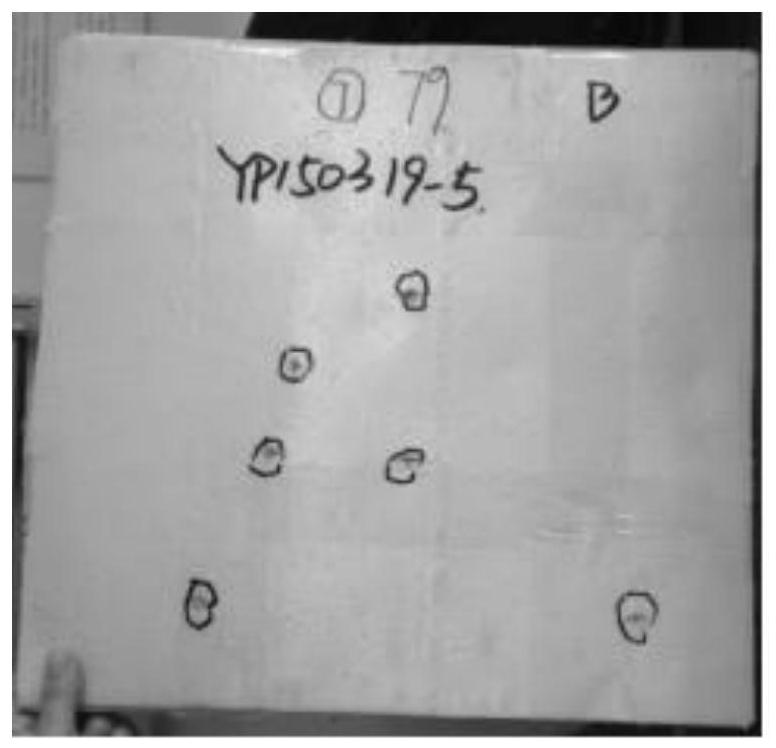

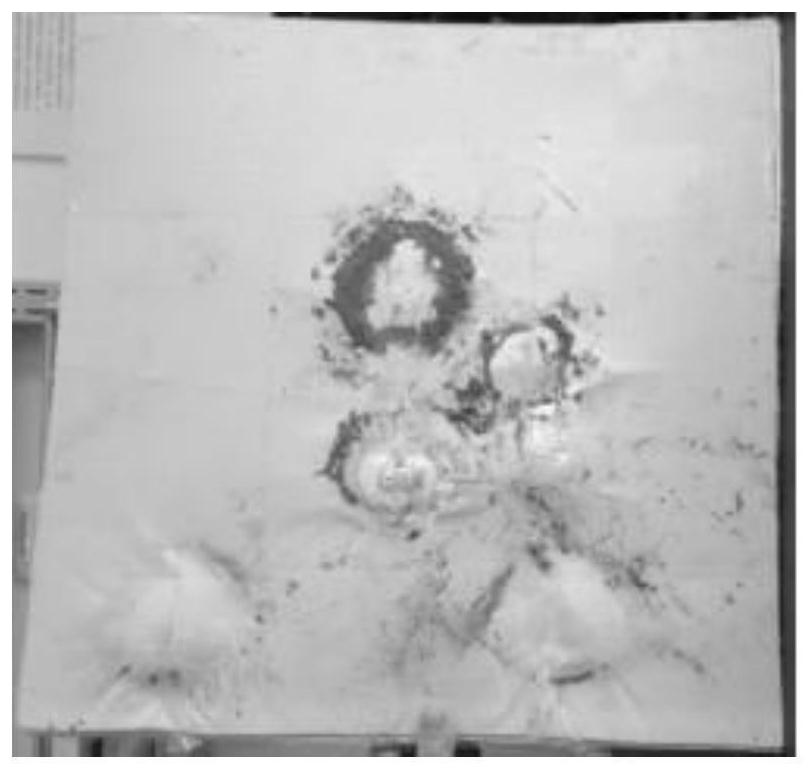

[0057] Note: ①The size of the materials in the table is 40cm×40cm; ②The target piece for the ballistic performance test is composed of 35 layers of aramid non-weft cloth; the target shooting test was tested by the No. 208 Institute of Chi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com