Heat-resistant modified mesoporous molecular sieve-based nitrogen oxide trapping catalyst as well as preparation method and application thereof

A technology for nitrogen oxides and catalysts, which is applied in the field of lean-burned nitrogen oxides trapping catalysts and their preparation, can solve problems such as poor heat resistance, and achieve the effects of improving thermal sintering resistance, improving thermal stability and reducing raw material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

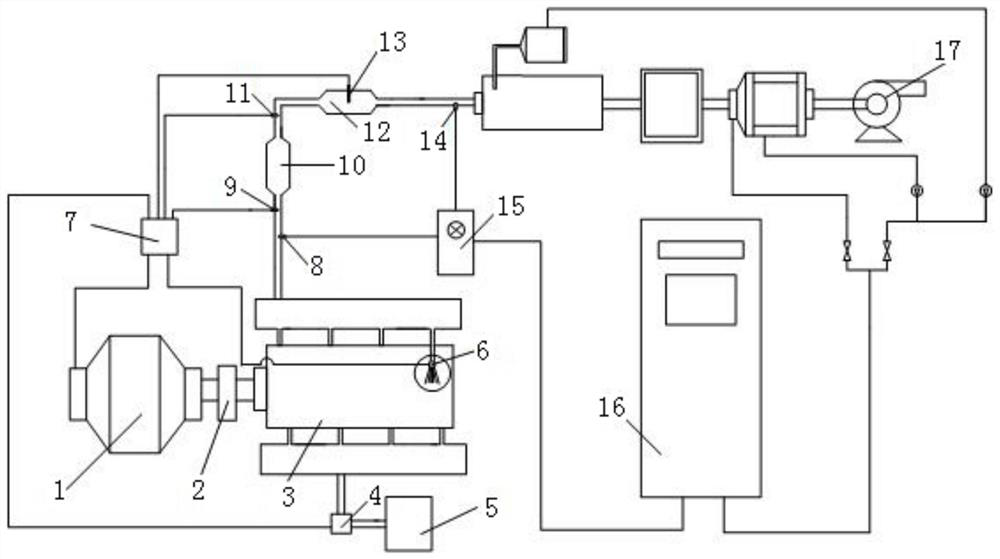

Method used

Image

Examples

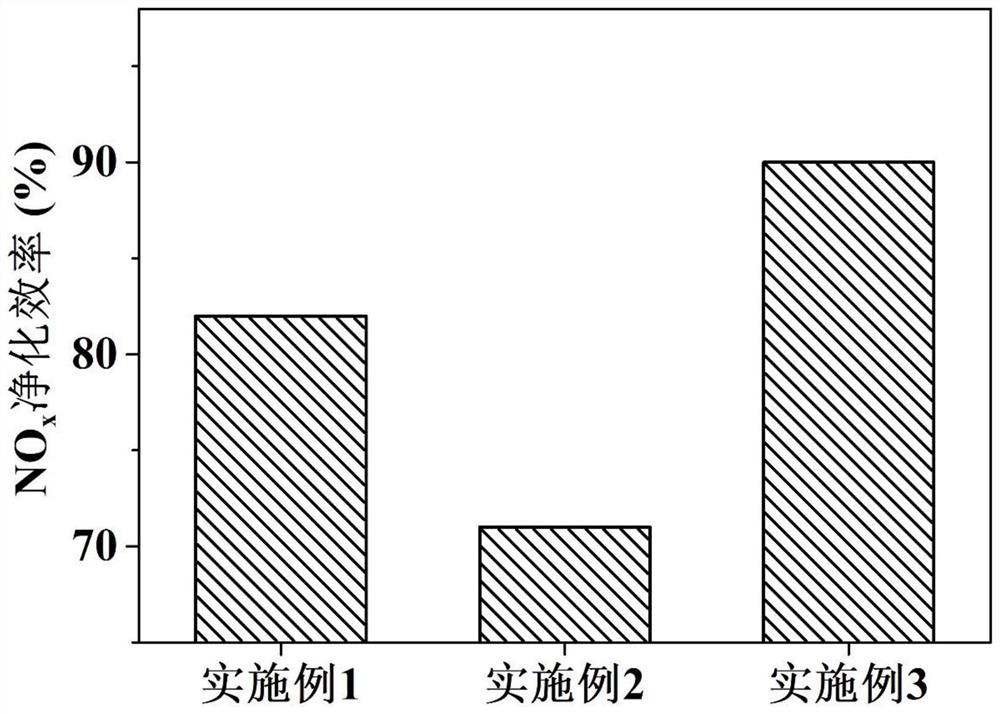

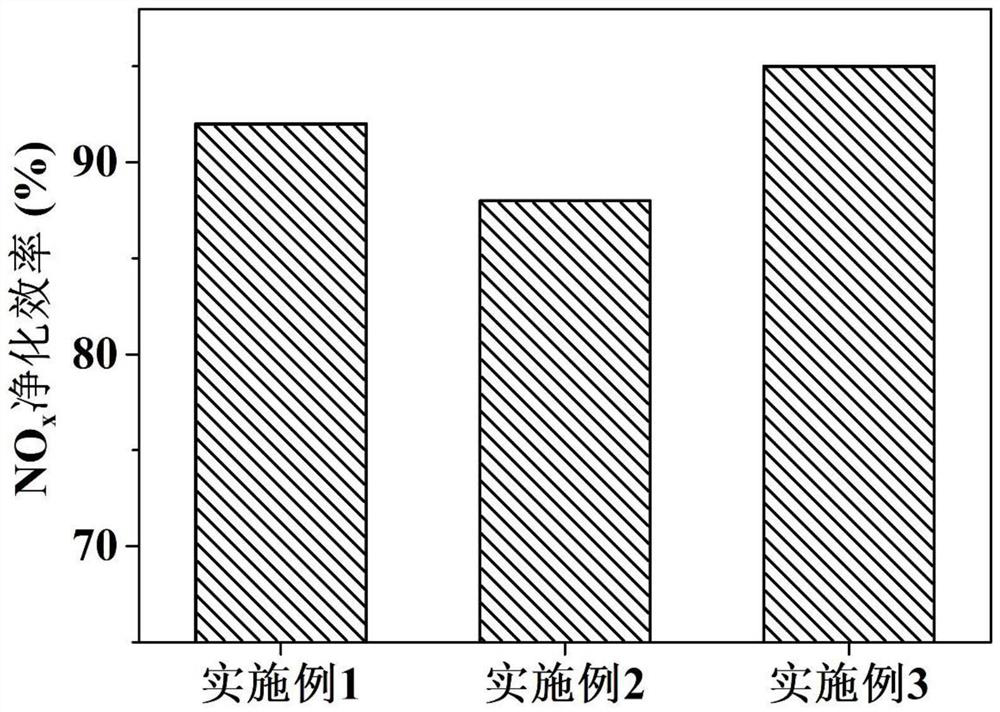

Embodiment 1

[0036] (1) Catalyst composition design

[0037] The following ratios are designed respectively: the mass percentages of Pd, Y and SBA-15 molecular sieve in the Pd-Y binary metal modified SBA-15 molecular sieve are: 15% / 15% / 70%, MgO, SrO and ZrO 2 The mass percentage is: 10% / 20% / 70%, γ-Al 2 O 3 and SiO 2 The mass percentage is: 80% / 20%, the mass percentage of the main catalytic active components, adsorbents, co-catalysts and coating additives is: 0.5% / 15% / 10% / 74.5%, and the planned configuration coating The slurry can generate 2000g of catalytic coating.

[0038] (2) Preparation of modified molecular sieves

[0039] Weigh 5.9g Y (NO 3 ) 3 ·4H 2 O and put it into 0.11L deionized water, and stir to prepare a solution; add 7g of SBA-15 molecular sieve to the solution, stir vigorously at 80°C for 8h, and then evaporate the water to dryness at 90°C. The dried solids were dried at 100 °C for 8 h, the dried solids were calcined at 550 °C for 1 h in an air atmosphere, and then ...

Embodiment 2

[0046] (1) Catalyst composition design

[0047] The following ratios were designed respectively: the mass percentages of Pd, Y and SBA-15 molecular sieve in the Pd-Y binary metal modified SBA-15 molecular sieve are: 1% / 10% / 89%, MgO, SrO and ZrO 2 The mass percentage is: 25% / 40% / 35%, γ-Al 2 O 3 and SiO 2 The mass percentage is: 70% / 30%, the mass percentage of the main catalytic active components, adsorbents, co-catalysts and coating additives is: 5% / 25% / 15% / 55%, and the planned configuration coating The slurry can generate 2000g of catalytic coating.

[0048] (2) Preparation of modified molecular sieves

[0049] Weigh 39.0g Y (NO 3 ) 3 ·4H 2 O and put it into 0.4L deionized water, and stir to prepare a solution; add 89g of SBA-15 molecular sieves to the solution, stir vigorously at 50°C for 16h, and then evaporate the water to dryness at 70°C. The dried solids were dried at 80°C for 16h, the dried solids were calcined at 550°C under air atmosphere for 1h, and then calci...

Embodiment 3

[0056] (1) Catalyst composition design

[0057] The following ratios are designed respectively: the mass percentages of Pd, Y and SBA-15 molecular sieves in the Pd-Y binary metal modified SBA-15 molecular sieve are: 10% / 10% / 80%, MgO, SrO and ZrO 2 The mass percentage is: 20% / 30% / 50%, γ-Al 2 O 3 and SiO 2The mass percentage is: 75% / 25%, the mass percentage of the main catalytic active components, adsorbents, co-catalysts and coating additives is: 5% / 20% / 10% / 65%, and the planned configuration coating The slurry can generate 2000g of catalytic coating.

[0058] (2) Preparation of modified molecular sieves

[0059] Weigh 39.0g Y (NO 3 ) 3 ·4H 2 O and put it into 0.2L deionized water, and stir to prepare a solution; add 80g SBA-15 molecular sieves to the solution, stir vigorously at 80°C for 8h, and then evaporate the water to dryness at 90°C. The dried solids were dried at 90°C for 12h, the dried solids were calcined at 500°C in an air atmosphere for 2h, and then calcined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com