Method for preparing nano-palladium catalyst by using protein assembly

A protein and assembly technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of uncontrollable nano-palladium particle size, high cost of preparation technology, Problems such as high energy consumption, to achieve the effect of improving size uniformity, improving catalytic efficiency, and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

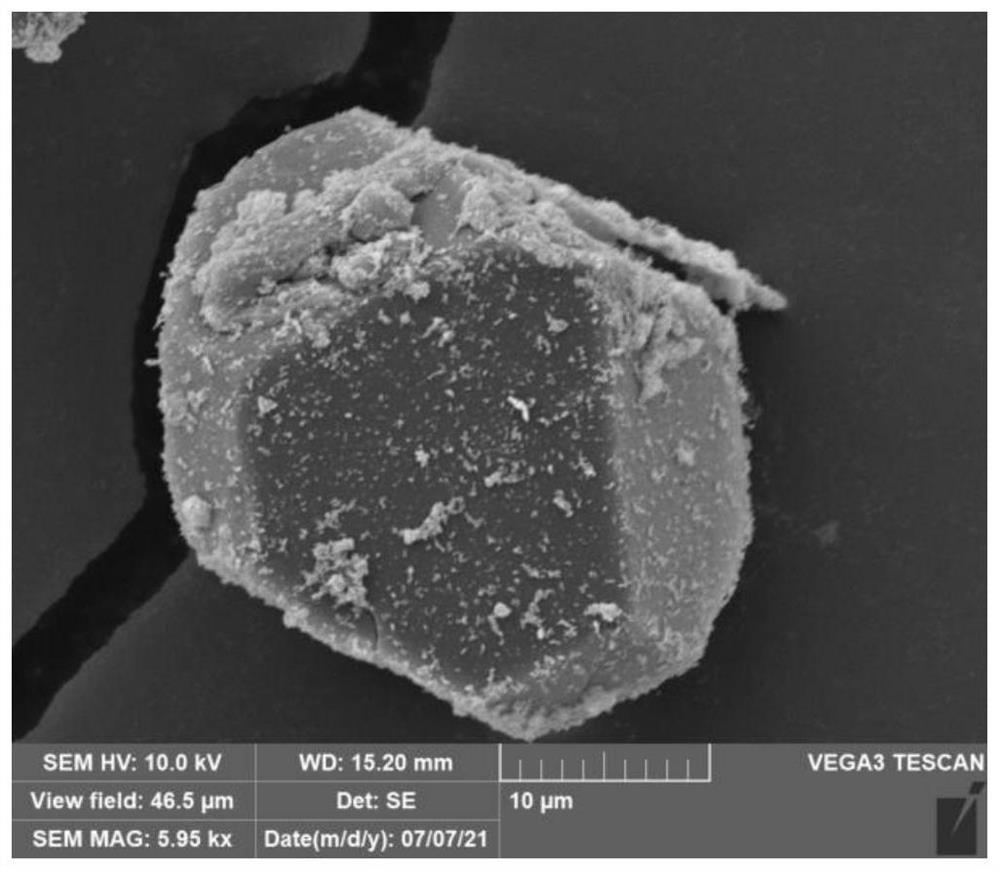

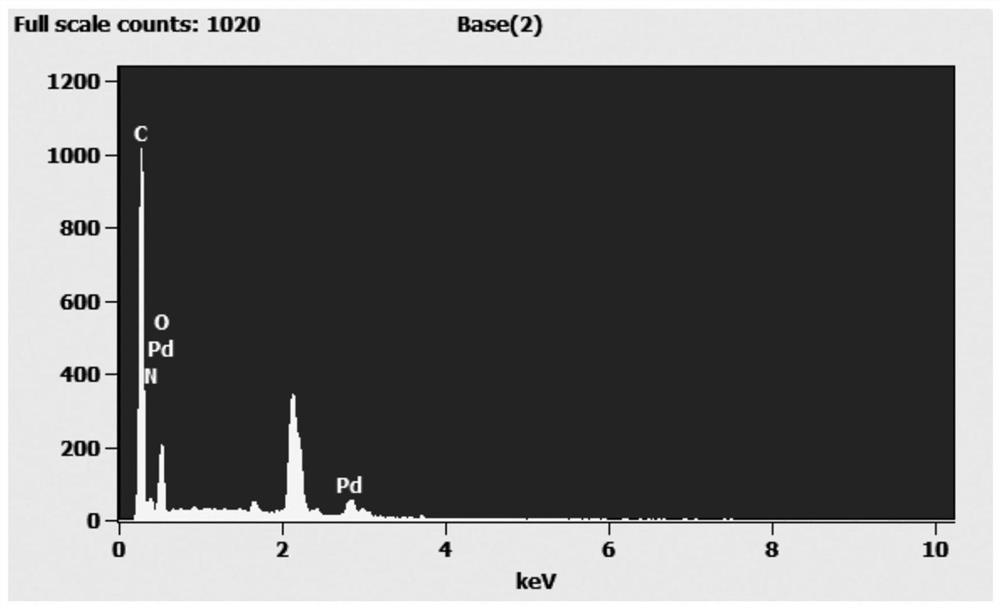

[0038] Embodiment 1 (hemoglobin crystal prepares nano-palladium catalyst)

[0039] The first step is the preparation of hemoglobin crystals.

[0040] 1) Mix the hemoglobin solution and the crystallizing agent solution at a ratio of 1:1 to obtain a hemoglobin crystallizing solution.

[0041] The crystallizing agent solution is: 20% polyethylene glycol, 0.2M succinic acid, pH 7.0.

[0042] 2) The hemoglobin crystallisation solution was allowed to stand at 20°C for 1 to 3 days.

[0043] 3) Collect hemoglobin crystals by centrifugation and resuspend the hemoglobin crystals with a crystallizing agent solution to obtain a hemoglobin crystal suspension.

[0044] 4) Mix the hemoglobin crystal suspension with the glutaraldehyde solution to obtain cross-linked hemoglobin crystals.

[0045] 5) Wash the hemoglobin crystals with deionized water and freeze-dry to obtain the final cross-linked hemoglobin crystals.

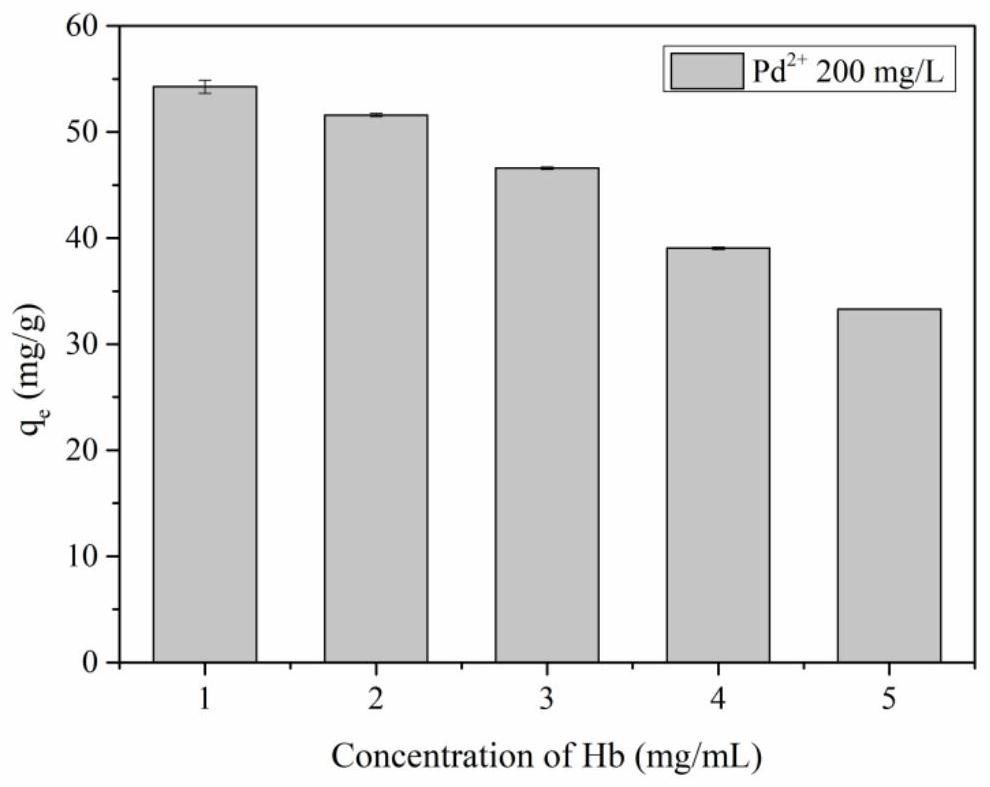

[0046] Step 2, adding the hemoglobin crystals into deionized water to di...

Embodiment 2

[0064] Embodiment 2 (hemoglobin assembly prepares nano-palladium catalyst)

[0065] Step 1, preparation of hemoglobin assembly.

[0066] 1) Mix the hemoglobin solution and the precipitant solution at a ratio of 1:1 to obtain a hemoglobin assembly solution.

[0067] The precipitant solution is: 20% polyethylene glycol, pH 7.0.

[0068] 2) The hemoglobin assembly solution was allowed to stand at 20°C for 1 to 3 days.

[0069] 3) Collect the hemoglobin assembly by centrifugation and resuspend the hemoglobin assembly with a precipitant solution to obtain a hemoglobin assembly suspension.

[0070] 4) Mixing the hemoglobin assembly suspension with the glutaraldehyde solution to obtain a cross-linked hemoglobin assembly.

[0071] 5) Wash the hemoglobin assembly with deionized water, and obtain the final cross-linked hemoglobin assembly after freeze-drying.

[0072] Step 2, adding the hemoglobin assembly into deionized water to disperse evenly to obtain a hemoglobin assembly suspe...

Embodiment 3

[0087] Embodiment 3 (the preparation of nano-palladium catalyst by lysozyme crystal)

[0088] The first step is the preparation of lysozyme crystals.

[0089] 1) Mix the lysozyme solution and the crystallizing agent solution at a ratio of 1:1 to obtain a lysozyme crystallization solution.

[0090] The crystallizing agent solution is: 3%-6% NaCl.

[0091] 2) The lysozyme crystallization solution was allowed to stand at 4°C for 1 to 3 days.

[0092] 3) Collect lysozyme crystals by centrifugation and resuspend the lysozyme crystals with a crystallizing agent solution to obtain a lysozyme crystal suspension.

[0093] 4) Mix the lysozyme crystal suspension with the glutaraldehyde solution to obtain cross-linked lysozyme crystals.

[0094] 5) Wash the lysozyme crystals with deionized water and freeze-dry to obtain the final cross-linked lysozyme crystals.

[0095] Step 2: Add the lysozyme crystals into deionized water and disperse them uniformly to obtain a lysozyme crystal susp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com