Sodium-ion battery metal selenide negative electrode material and preparation method and application thereof

A metal selenide, sodium-ion battery technology, applied in battery electrodes, selenium/tellurium compounds, chemical instruments and methods, etc., can solve problems such as poor electronic conductivity, increase capacitance behavior, solve poor electronic conductivity, and improve ion diffusion The effect of dynamics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

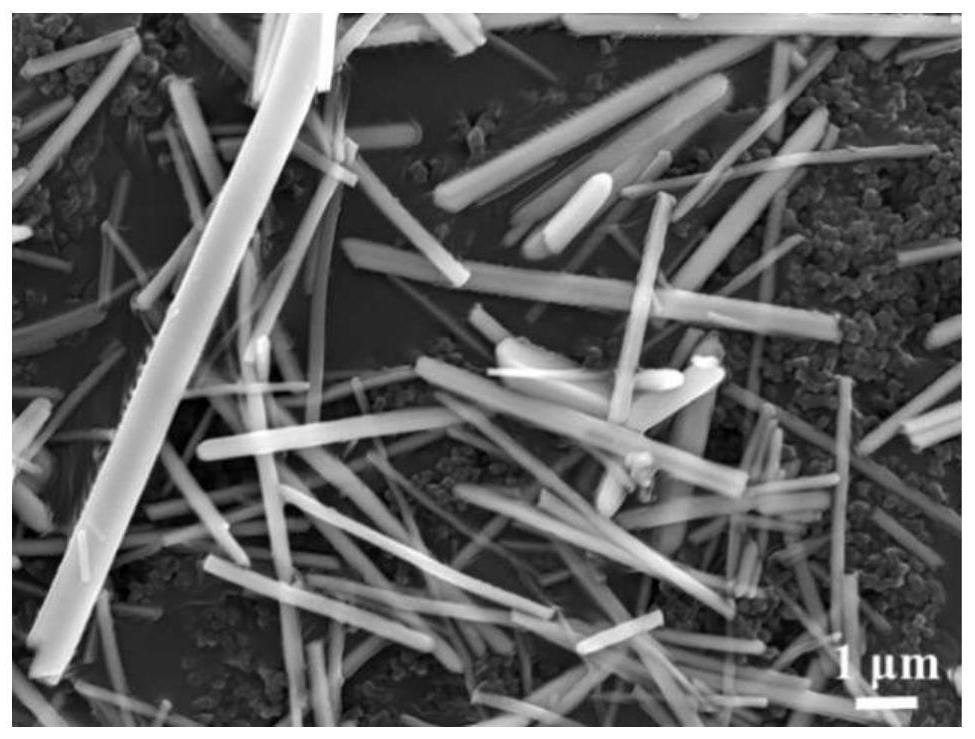

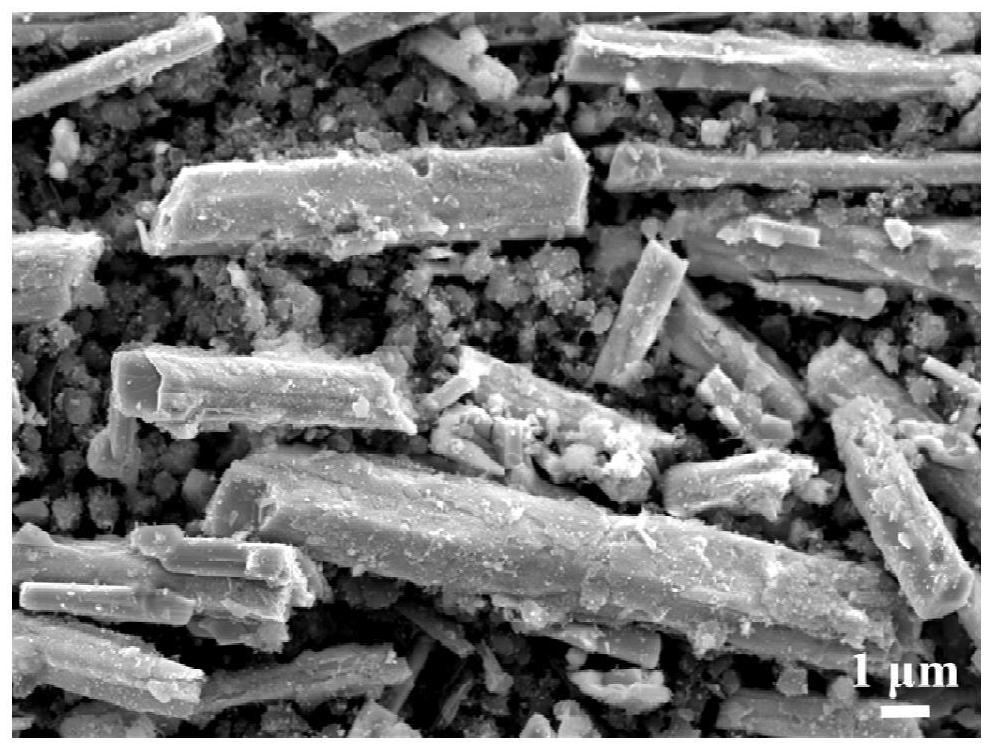

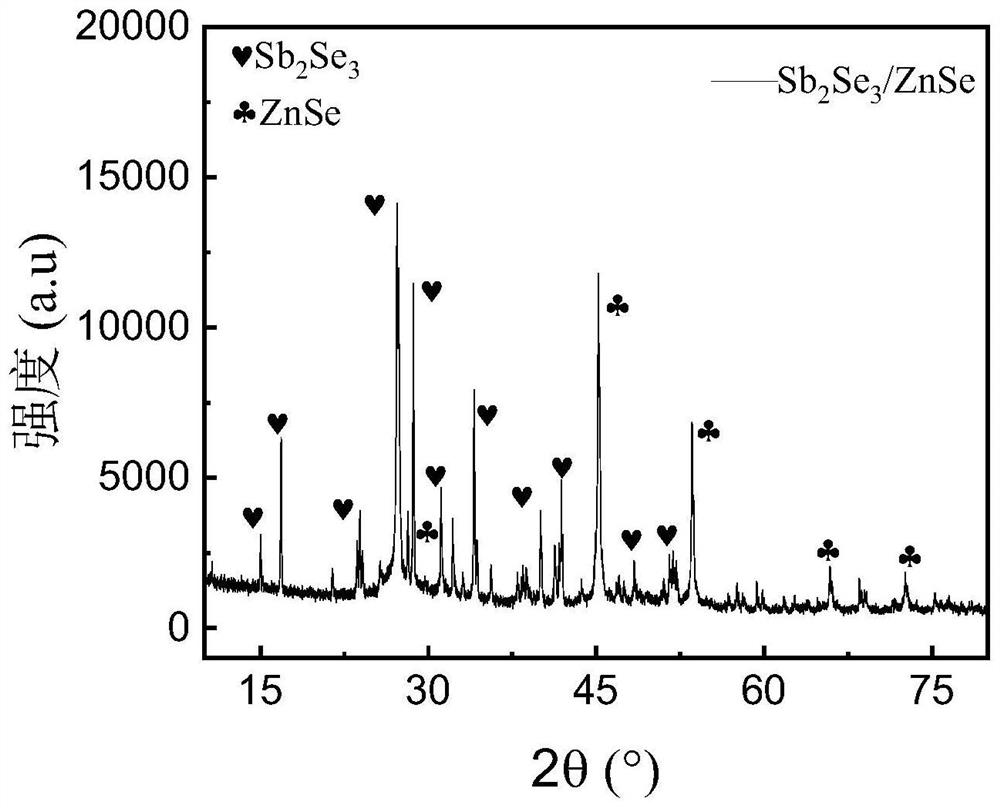

Embodiment 1

[0036] A method for preparing a metal selenide negative electrode material for a sodium ion battery, comprising the following steps:

[0037] Step (1): Weigh 4.8 g of antimony triselenide (Sb 2 Se 3 ) and 5.8 g of polyvinylpyrrolidone (PVP) were uniformly mixed and dissolved in 1 L of methanol solution.

[0038] Step (2): add 11.9g of zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O), stir at 30°C for 48h to Sb 2 Se 3 with Zn(NO 3 ) 2 ·6H 2 O is uniformly dispersed in methanol solution to form solution A.

[0039] Step (3): Dissolve 49.2 g of 2-methylimidazole in 1 L of methanol solution to form solution B.

[0040] Step (4): slowly add solution B to solution A, and stir vigorously for 30 min until the reaction is complete. Centrifuge and wash three times under the condition of rotating speed 8000rpm, and the obtained product was placed in a vacuum drying box and dried at 80°C for 12h.

[0041] Step (5): The obtained precursor is heat-treated in a tube furnace at 800°...

Embodiment 2

[0047] A method for preparing a metal selenide negative electrode material for a sodium ion battery, comprising the following steps:

[0048] Step (1): Weigh 4.8 g of antimony triselenide (Sb 2 Se 3 ) and 5.8 g of polyvinylpyrrolidone (PVP) were uniformly mixed and dissolved in 1 L of methanol solution.

[0049] Step (2): add 2.9g zinc nitrate hexahydrate (Zn(NO) to above-mentioned solution 3 ) 2 ·6H 2 O), stir at 30°C for 48h to Sb 2 Se 3 with Zn(NO 3 ) 2 ·6H 2 O is uniformly dispersed in methanol solution to form solution A.

[0050] Step (3): Dissolve 16.4 g of 2-methylimidazole in 1 L of methanol solution to form solution B.

[0051] Step (4): slowly add solution B to solution A, and stir vigorously for 30 min until the reaction is complete. Centrifuge and wash three times under the condition of rotating speed 8000rpm, and the obtained product was placed in a vacuum drying box and dried at 80°C for 12h.

[0052] Step (5): The obtained precursor is heat-treated ...

Embodiment 3

[0054] A method for preparing a metal selenide negative electrode material for a sodium ion battery, comprising the following steps:

[0055] Step (1): Weigh 4.8 g of antimony triselenide (Sb 2 Se 3 ) and 5.8 g of polyvinylpyrrolidone (PVP) were uniformly mixed and dissolved in 1 L of methanol solution.

[0056] Step (2): add 14.9g of zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O), stir at 30°C for 48h to Sb 2 Se 3 with Zn(NO 3 ) 2 ·6H 2 O is uniformly dispersed in methanol solution to form solution A.

[0057] Step (3): Dissolve 82.1 g of 2-methylimidazole in 1 L of methanol solution to form solution B.

[0058] Step (4): slowly add solution B to solution A, and stir vigorously for 30 min until the reaction is complete. Centrifuge and wash three times under the condition of rotating speed 8000rpm, and the obtained product was placed in a vacuum drying box and dried at 80°C for 12h.

[0059] Step (5): The obtained precursor is heat-treated in a tube furnace at 800°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com