Low-shrinkage engineering repair material and preparation method thereof

A repair material, low shrinkage technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as insufficient volume stability of repair materials, overcome compatibility differential layer segregation, reduce early stage The effect of shrinkage, strength and durability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

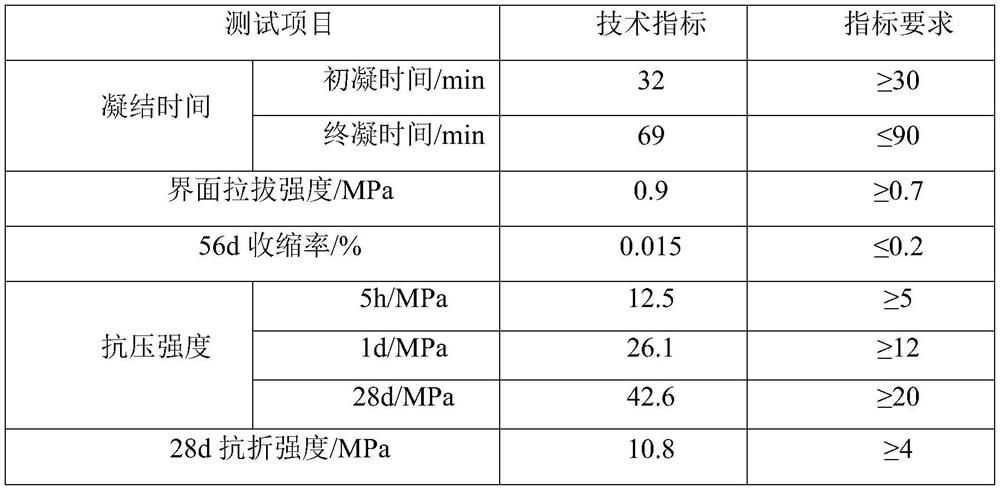

Embodiment 1

[0030] A low-shrinkage engineering repair material, the mass ratio of each component in the raw material is: cement-emulsified asphalt-water-based epoxy resin composite base mortar: fine aggregate: organic nano-montmorillonite: water reducing agent: defoaming agent: Retarder: water = 100:180:4:0.4:0.0003:0.4:10; the cement-emulsified asphalt-water-based epoxy resin composite base mortar is composed of cement, emulsified asphalt, epoxy resin, and curing agent in a mass ratio. 100:50:6:6 prepared.

[0031] The cement is 52.5 fast-hardening sulfoaluminate cement; the emulsified asphalt is anionic high-viscosity emulsified asphalt; the epoxy resin is E51 type epoxy resin; and the curing agent is a non-ionic self-emulsifying curing agent.

[0032] The water reducing agent is a polycarboxylate water reducing agent; the defoaming agent is a polyether type defoaming agent; the setting retarder is analytical pure boric acid; the fine aggregate is ultra-fine porous shale ceramsite It i...

Embodiment 2

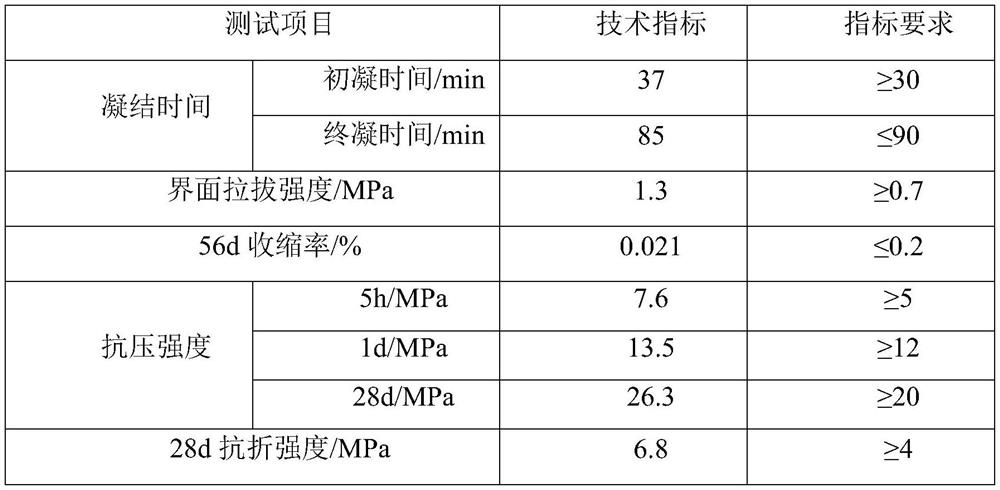

[0044] A low-shrinkage engineering repair material, the mass ratio of each component in the raw material is: cement-emulsified asphalt-water-based epoxy resin composite base mortar: fine aggregate: organic nano-montmorillonite: water reducing agent: defoaming agent: Retarder: water = 100:200:5:0.3:0.0003:0.1:5; the cement-emulsified asphalt-water-based epoxy resin composite base mortar is composed of cement, emulsified asphalt, epoxy resin, and curing agent in a mass ratio. 100:80:10:10 prepared.

[0045] The cement is 42.5 fast-hardening sulfoaluminate cement; the emulsified asphalt is anionic high-viscosity emulsified asphalt; the epoxy resin is E51 type epoxy resin; and the curing agent is a non-ionic self-emulsifying curing agent.

[0046] The water reducing agent is a polycarboxylate water reducing agent; the defoaming agent is a polyether defoaming agent; the retarder is sodium gluconate; the fine aggregate is ultra-fine porous shale ceramsite It is mixed with quartz sa...

Embodiment 3

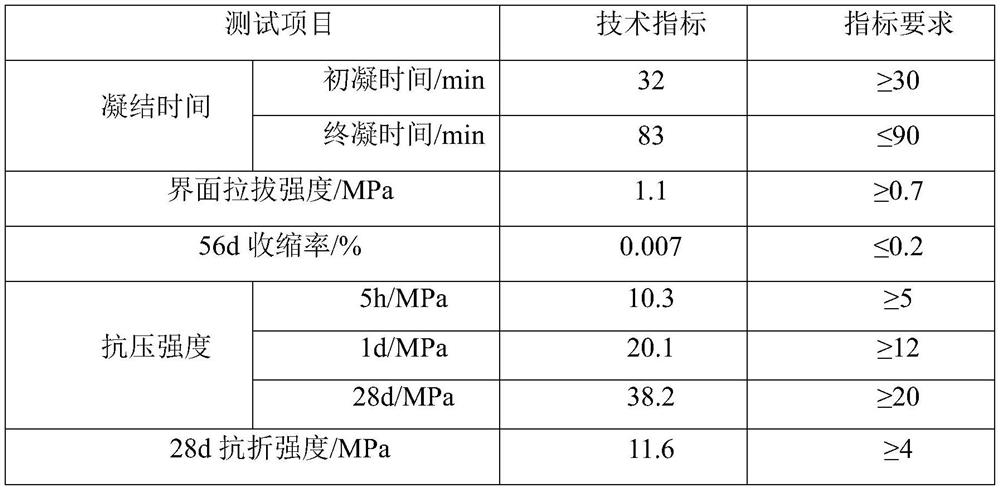

[0059] A low-shrinkage engineering repair material, the mass ratio of each component in the raw material is: cement-emulsified asphalt-water-based epoxy resin composite base mortar: fine aggregate: organic nano-montmorillonite: water reducing agent: defoaming agent: Retarder: water = 100:160:6:0.6:0.0006:0.3:5 The cement-emulsified asphalt-water-based epoxy resin composite base mortar is composed of cement, emulsified asphalt, epoxy resin, and curing agent in a mass ratio of 100 :50:10:10.

[0060] The cement is 42.5 fast-hardening sulfoaluminate cement; the emulsified asphalt is anionic high-viscosity emulsified asphalt; the epoxy resin is E51 type epoxy resin; and the curing agent is a non-ionic self-emulsifying curing agent.

[0061] The water reducing agent is a polycarboxylate water reducing agent; the defoaming agent is a polyether type defoaming agent; the retarder is analytical pure boric acid; the fine aggregate is ultra-fine porous shale ceramsite It is mixed with q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com