Photoresponse type metal organic polyhedral catalyst, preparation method and application of photoresponse type metal organic polyhedral catalyst

A metal-organic, light-responsive technology, applied in organic compound/hydride/coordination complex catalysts, organic chemistry, copper-organic compounds, etc., which can solve problems such as catalyst and product separation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

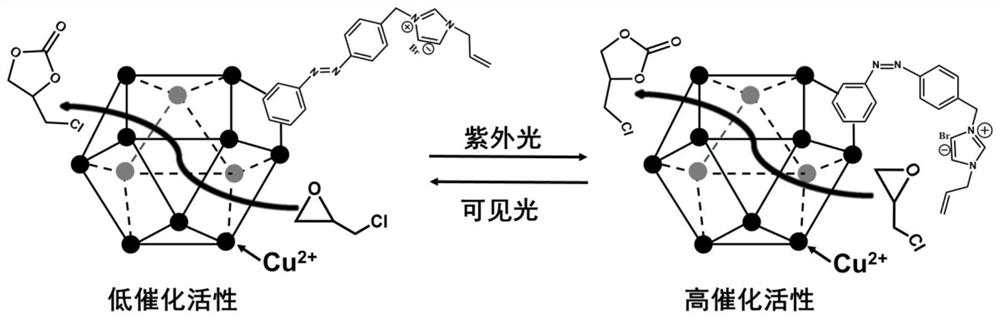

AI Technical Summary

Problems solved by technology

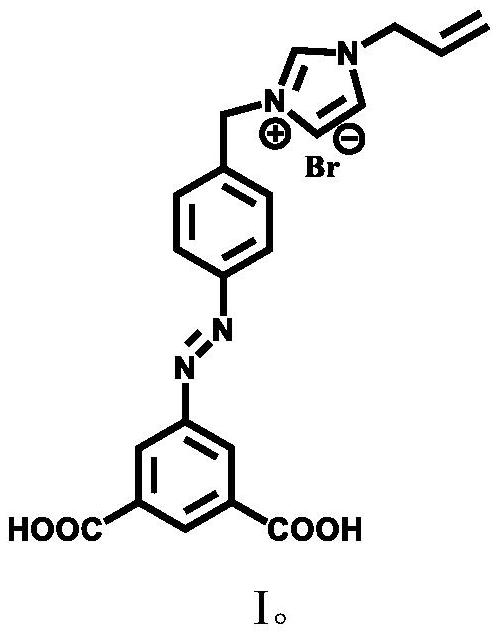

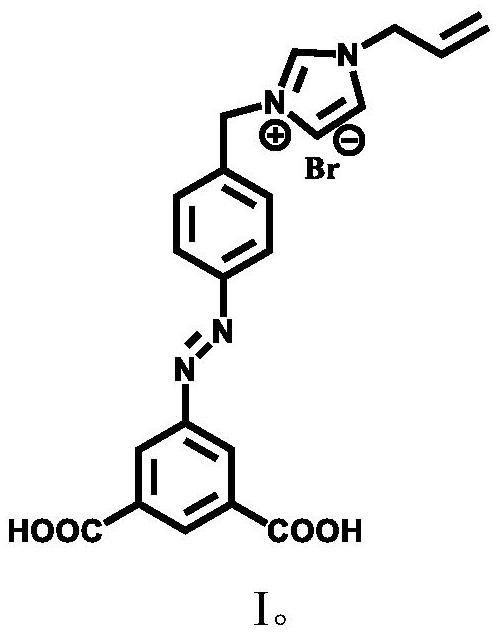

Method used

Image

Examples

Embodiment 1

[0031] Weigh 50 mg of L1 into a 20 mL reaction flask, add 5 mL of a mixed solution of N,N-dimethylformamide and methanol (v / v=4:1), and sonicate for a period of time to obtain an orange clear solution, denoted as bottle A; Weigh 40 mg of copper acetate monohydrate and dissolve it in 5 mL of a mixed solution of N,N-dimethylformamide and methanol (v / v=4:1), and ultrasonically until it is fully dissolved, which is recorded as bottle B. Slowly add the solution of bottle B to bottle A, and ultrasonicate for 5 minutes to make it evenly mixed to obtain a green clear solution. After the reaction, 20 mL of N,N-dimethylformamide / anhydrous methanol solution was sequentially added to the glass bottle for solvent exchange, and each solvent exchange was performed once every 12 h, and each solvent was exchanged three times. Finally, the green powder obtained by vacuum drying at 80 °C for 6 h is a photoresponsive metal-organic polyhedral catalyst.

[0032] Photoresponse test: Disperse the pr...

Embodiment 2

[0035] Weigh 33mg L1 and 6mg 5-aminoisophthalic acid (molar ratio L1:L2=2:1) into a 20mL reaction flask, add 5mL of a mixed solution of N,N-dimethylformamide and methanol (v / v =4:1), ultrasonicate for a period of time to obtain an orange clear solution, denoted as bottle A; weigh 40 mg of copper acetate monohydrate and dissolve it in 5 mL of a mixed solution of N,N-dimethylformamide and methanol (v / v=4 : 1), ultrasonic until it is fully dissolved, recorded as B bottle. Slowly add the solution of bottle B to bottle A, and ultrasonicate for 5 minutes to make it evenly mixed to obtain a green clear solution. After the reaction, 20 mL of N,N-dimethylformamide / anhydrous methanol solution was sequentially added to the glass bottle for solvent exchange, and each solvent exchange was performed once every 12 h, and each solvent was exchanged three times. Finally, the green powder obtained by vacuum drying at °C for 6 h is a photoresponsive metal-organic polyhedron catalyst.

[0036...

Embodiment 3

[0039]Weigh 25mg L1 and 9mg 5-aminoisophthalic acid (molar ratio L1:L2=1:1) into a 20mL reaction flask, add 5mL of a mixed solution of N,N-dimethylformamide and methanol (v / v =4:1), ultrasonicate for a period of time to obtain an orange clear solution, denoted as bottle A; weigh 40 mg of copper acetate monohydrate and dissolve it in 5 mL of a mixed solution of N,N-dimethylformamide and methanol (v / v=4 : 1), ultrasonically until it is fully dissolved, recorded as B bottle. Slowly add the solution of bottle B to bottle A, and ultrasonicate for 5 minutes to make it evenly mixed to obtain a green clear solution. After the reaction, 20 mL of N,N-dimethylformamide / anhydrous methanol solution was sequentially added to the glass bottle for solvent exchange, and each solvent exchange was performed once every 12 h, and each solvent was exchanged three times. Finally, the green powder obtained by vacuum drying at 80 °C for 6 h is a photoresponsive metal-organic polyhedral catalyst.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com