Environment-friendly flame-retardant transparent polyester material and preparation method thereof

A polyester material and transparent technology, applied in the field of environmentally friendly flame-retardant transparent polyester materials and its preparation, can solve problems such as gas pollution, heavy metal pollution, and impact on the fire-fighting process, and achieve easy wetting, good flame-retardant performance, and improved The effect of flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

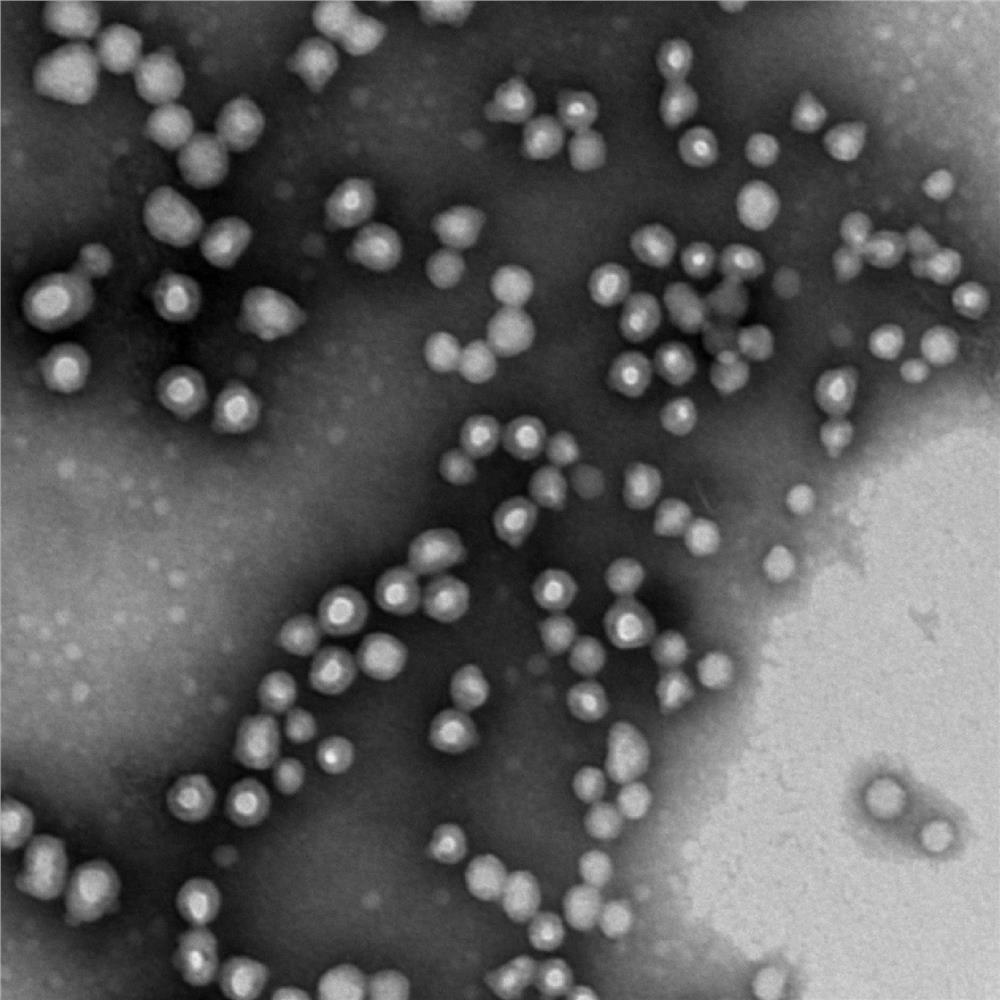

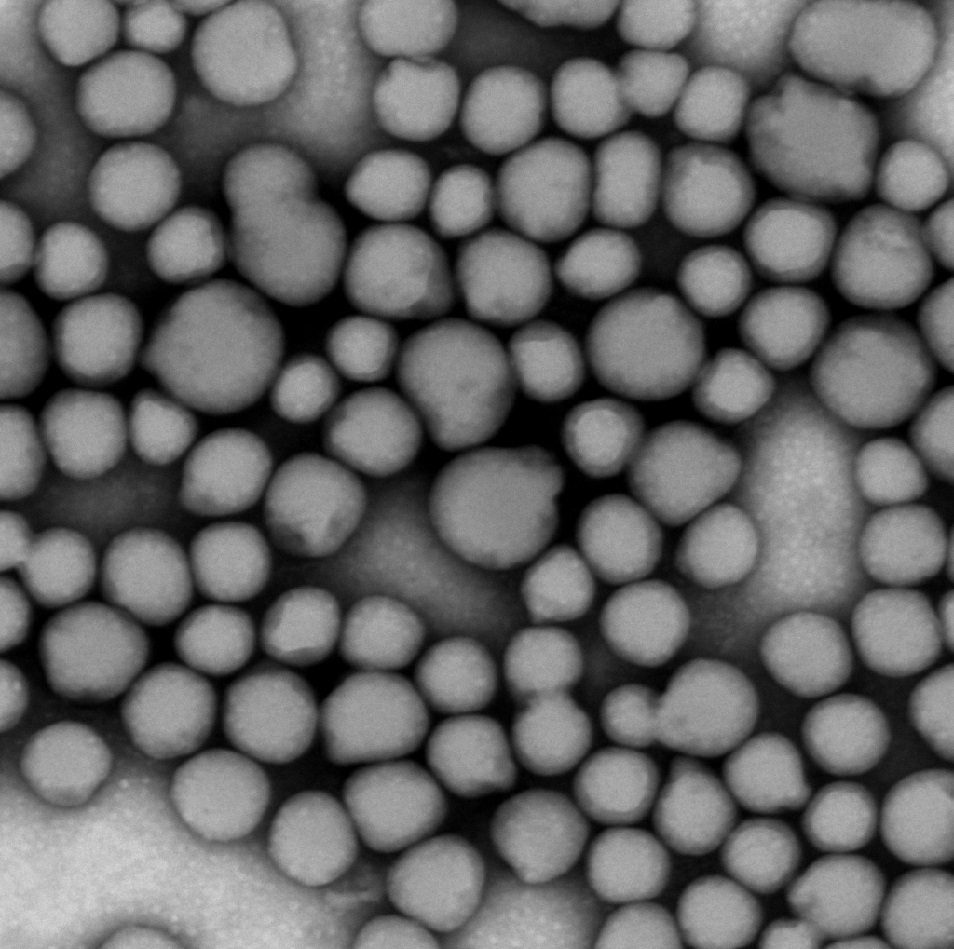

[0028] This embodiment provides an environmentally friendly flame retardant transparent polyester material, which in parts by mass includes thermoplastic polyester resin (PET) and a flame retardant, and every 100 parts of thermoplastic polyester resin corresponds to 1 part of flame retardant; The flame retardant is a core-shell structure montmorillonite-silicon-fluorine modified polypropylene material, and both montmorillonite and fluorine and silicon elements are located in the core.

[0029] In parts by mass, the flame retardant includes the following raw materials: 50 parts of deionized water, 1 part of initiator, 0.5 part of buffer, 3.5 parts of emulsifier, 2 parts of silane coupling agent, 4 parts of nano-montmorillonite, 2 parts of fluoroolefins; 40 parts of hard monomers, 10 parts of soft monomers; the particle size range of the nano-montmorillonite is 10-30 nm; the emulsifier includes cetyltrimethylammonium bromide and allyloxynonylphenol polyoxyethylene ether sulfate ...

Embodiment 2

[0061] This example is basically the same as Example 1, except that: in parts by mass, the flame retardant includes the following raw materials: 60 parts of deionized water, 2 parts of initiator, 1.0 part of buffer, 4.5 parts of emulsifier, 3 parts of Parts of silane coupling agent, 5 parts of nano-montmorillonite, 3 parts of fluoroolefin; 30 parts of hard monomers, 20 parts of soft monomers; the emulsifier includes sodium dodecylbenzenesulfonate and allyloxynonane ammonium phenol polyoxyethylene ether sulfate, and the ratio is 3:1.5; the fluorinated olefin is fluorinated ethylene; the silane coupling agent is vinyltrimethoxysilane; the soft monomer includes 6 parts of methyl Hexyl acrylate, 9 parts ethyl acrylate; 5 parts butyl acrylate; hard monomers include 10 parts t-butyl methacrylate, 10 parts styrene, 10 parts acrylamide; each 100 parts thermoplastic polyester resin corresponds to 0.8 parts of flame retardant.

[0062] The test method of flame retardant performance is ...

Embodiment 3

[0064] This example is basically the same as Example 1, except that: in parts by mass, the flame retardant includes the following raw materials: 60 parts of deionized water, 1 part of initiator, 0.7 part of buffer, 4.5 parts of emulsifier, 3 parts of Parts of silane coupling agent, 5 parts of nano-montmorillonite, 3 parts of fluoroolefin; 40 parts of hard monomer, 10 parts of soft monomer; the fluoroolefin is tetrafluoroethylene; the silane coupling agent is vinyl triethoxysilane; the soft monomers include 3 parts of hexyl methacrylate and 7 parts of butyl acrylate; the hard monomers include 11 parts of vinyl acetate, 16 parts of methyl methacrylate and 13 parts of styrene; each The 100 parts of thermoplastic polyester resin corresponds to 0.8 part of flame retardant.

[0065] The test method of flame retardant performance is the same as that of Example 1, and the flame retardant performance test of each test in this implementation has reached the V-0 level.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com