Root-promoting soil conditioner and preparation method thereof

A technology of soil conditioner and potassium fulvic acid, which is applied in the fields of bio-organic part treatment, agriculture, and agricultural gas emission reduction. Effects of total root length, increased saturated hydraulic conductivity, and increased aerated porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

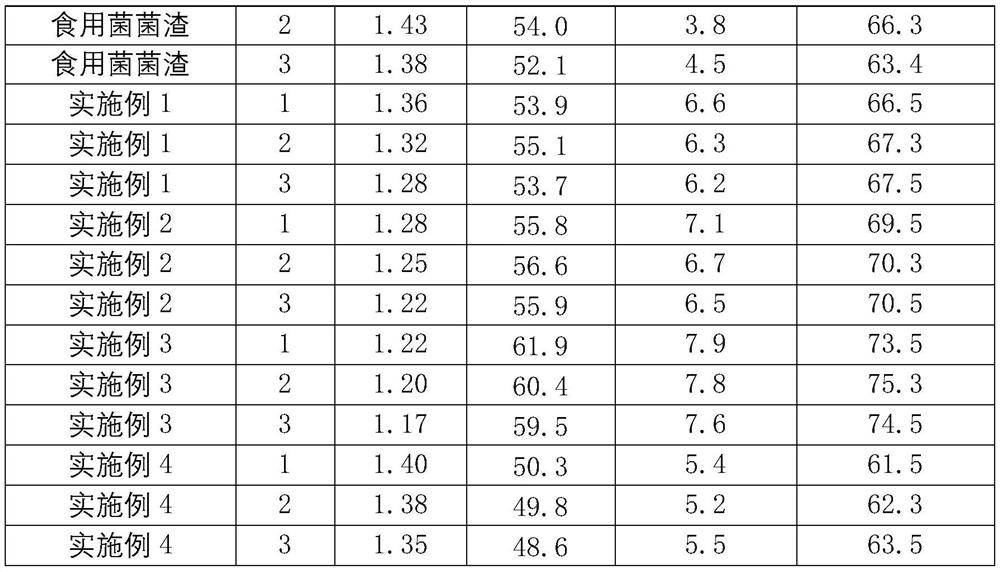

Embodiment 1

[0027] A root-promoting soil conditioner, in parts by weight, comprising 25 parts of biomass charcoal, 25 parts of coconut bran, 25 parts of edible fungus residues, 2 parts of potassium fulvic acid, 0.5 parts of Bacillus subtilis, 0.5 parts of phosphoric acid Potassium dihydrogen, 0.05 part of sodium indole butyrate, 0.05 part of γ-polyglutamic acid, 25 parts of water; the preparation method is: potassium fulvic acid, potassium dihydrogen phosphate, sodium indole butyrate and γ-poly Glutamic acid is dissolved in water, then mixed with coconut bran evenly, and then mixed with biochar, edible fungus residue, Bacillus subtilis, placed for 24 hours, and stirred.

Embodiment 2

[0029] A root-promoting soil conditioner, in parts by weight, comprising 25 parts of biomass charcoal, 25 parts of coconut bran, 25 parts of edible fungus residue, 2 parts of chitosan, 2 parts of potassium fulvic acid, 2 parts of poly Acrylamide, 0.5 part of Bacillus subtilis, 0.5 part of potassium dihydrogen phosphate, 0.05 part of sodium indole butyrate, 0.05 part of γ-polyglutamic acid, 25 parts of water; the preparation method is: chitosan, fulvic acid Potassium, polyacrylamide, potassium dihydrogen phosphate, sodium indole butyrate and γ-polyglutamic acid are dissolved in water, then mixed with coconut bran evenly, and then mixed with biochar, edible fungus residue, and Bacillus subtilis. Place for 24h and stir.

Embodiment 3

[0031]A root-promoting soil conditioner, in parts by weight, comprising 25 parts of biomass charcoal, 25 parts of coconut bran, 25 parts of edible fungus residue, 2 parts of chitosan, 2 parts of potassium fulvic acid, 2 parts of poly Acrylamide, 0.5 part of Bacillus subtilis, 0.5 part of potassium dihydrogen phosphate, 0.05 part of sodium indole butyrate, 1.5 part of alginic acid, 0.05 part of gamma-polyglutamic acid, 0.4 part of stevioside, 25 parts of water; its preparation The method is: dissolve chitosan, potassium fulvic acid, polyacrylamide, potassium dihydrogen phosphate, sodium indole butyrate, alginic acid, γ-polyglutamic acid and stevioside in water, then mix with coconut bran Evenly, then mixed with biochar, edible fungus residue, Bacillus subtilis, placed for 24 hours, and stirred.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com