Reaction circulation rectification process method for producing ethyl methyl carbonate and diethyl ester

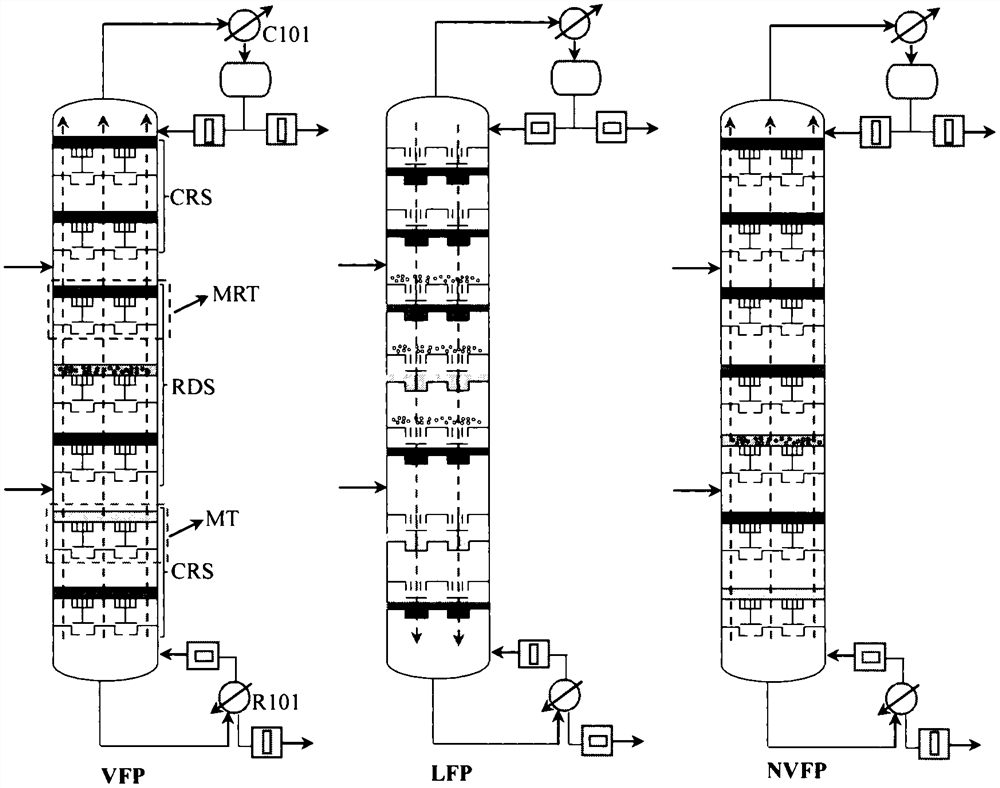

A technology of ethyl methyl carbonate and diethyl carbonate, which is applied in the field of reaction cycle rectification technology for the production of ethyl methyl carbonate and diethyl carbonate, can solve the problem of low single-pass conversion rate of raw materials and low separation efficiency of trays, and increase process throughput. Improve the efficiency of reaction and separation, increase flux, and reduce flow resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In the present invention, the molar ratio of dimethyl carbonate to ethanol in the raw material is set to 1:1, the number of plates in the common rectifying section of the reaction cycle rectification is 15, the number of plates in the reactive rectifying section is 20, and the number of plates in the common stripping section is 15. The number of stage plates is 30, the operating pressure is 101.325Kpa, the gas phase cycle operation time is 35s, the liquid phase cycle operation time is 5s, the catalyst loaded on the reaction distillation section plate plate is alkali metal oxide MgO / HZSM-5, the reaction The loading amount of the solid catalyst on the rectification tray is 30Kg, the cycle feed amount is 0.4kmol / cycle, and the steam amount in the gas phase operation stage is 1kmol / min.

[0024] After the dimethyl carbonate and ethanol raw materials pass through the above process, the one-pass conversion rate of dimethyl carbonate is 65%, the one-pass yield of methyl ethyl c...

Embodiment 2

[0026] In the present invention, the molar ratio of dimethyl carbonate to ethanol in the raw material is set to 1.2:1, the number of plates in the common rectifying section of the reaction cycle rectification is 15, the number of plates in the reactive rectification section is 25, and the number of plates in the common stripping section is 15. The number of stage plates is 30, the operating pressure is 101.325Kpa, the gas phase cycle operation time is 40s, the liquid phase cycle operation time is 5s, the catalyst loaded on the reaction distillation section plate plate is alkali metal oxide MgO / HZSM-5, and the reaction The loading amount of the solid catalyst on the rectification tray is 35Kg, the cycle feed amount is 0.44kmol / cycle, and the steam amount in the gas phase operation stage is 1.2kmol / min.

[0027] After the dimethyl carbonate and ethanol raw materials are subjected to the above-mentioned process, the one-pass conversion rate of dimethyl carbonate is 62%, the one-pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com