Gasoline-resistant TPE material

A technology of gasoline resistance and oil resistance additives, applied in the field of thermoplastic elastomers, can solve the problems of poor mechanical properties, poor gasoline resistance, poor high and low temperature impact properties, etc. The effect of gasoline resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

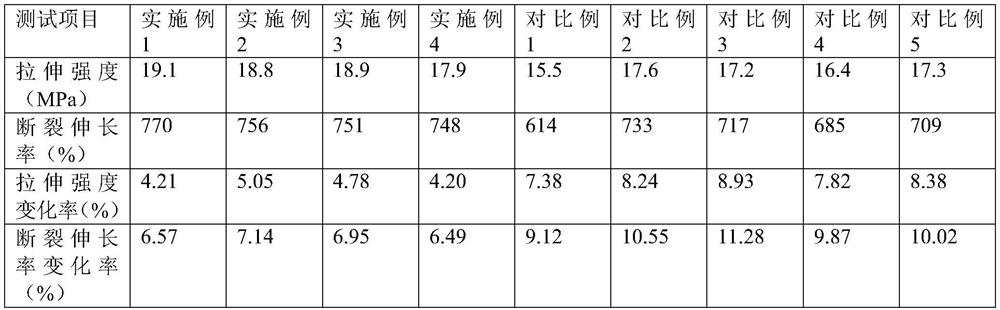

Examples

preparation example Construction

[0032] The preparation method of above-mentioned oil-resistant auxiliary agent comprises the steps:

[0033] (1) Put Ti 3 C 2 T x Prepare Ti with a concentration of 2-6 mg / mL in tetrahydrofuran solution 3 C 2 T x Dispersion, add acrylamide and then stir, and then add a mixed solution containing styrene, acrylonitrile, tert-dodecyl mercaptan and ethanol to carry out polymerization reaction. The temperature is 180~220℃ for 0.5~1h; the Ti 3 C 2 T x , the mass ratio of acrylamide, styrene and acrylonitrile is 0.1~1:10~20:25~40:25~40;

[0034] (2) adding the resultant in step (1) to a compound containing chitosan with a molecular weight of 2*10 4 ~10*10 4 In the acetic acid aqueous solution, the concentration of chitosan in the acetic acid aqueous solution of chitosan is 1-4 mg / mL, and the volume fraction of acetic acid is 3-10%; after stirring, add di-tert-butyl peroxide and maleic anhydride React at 30~60℃ for 5~8h, then slowly add molecular weight of 30*10 under stirr...

Embodiment 1

[0037] By weight, the gasoline-resistant TPE material includes the following raw materials: 40 parts SEBS rubber, 15 parts EPDM rubber, 15 parts

[0038] Polyethylene octene co-elastomer, 6 parts polypropylene, 3 parts monomer resin, 22 parts white oil and 15 parts oil resistance additives.

[0039] Among them, the content of ethylene structural units in the polyethylene octene co-elastomer is 40%, the content of octene structural units is 60%, the weight average molecular weight is 200kg / mol; the molecular weight of the monomer resin is 7000, and the glass transition temperature is Aromatic monomer resin at 130°C.

[0040] The preparation method of above-mentioned oil-resistant auxiliary agent comprises the steps:

[0041] (1) 50mg Ti 3 C 2 T x Add tetrahydrofuran solution to prepare Ti with a concentration of 5 mg / mL 3 C 2 T x Dispersion, add 1.5g of acrylamide and stir, then add a mixed solution containing 3g of styrene, 3g of acrylonitrile, 0.2g of tert-dodecyl merc...

Embodiment 2

[0044] By weight, the gasoline-resistant TPE material includes the following raw materials: 30 parts SEBS rubber, 15 parts EPDM rubber, 15 parts

[0045] Polyethylene octene co-elastomer, 8 parts polypropylene, 4 parts monomer resin, 20 parts white oil and 12 parts oil resistance additives.

[0046] Among them, the content of ethylene structural unit in polyethylene octene co-elastomer is 30%, the content of octene structural unit is 70%, the weight average molecular weight is 250kg / mol; the molecular weight of the monomer resin is 5000, and the glass transition temperature is Aromatic monomer resin at 110°C.

[0047] The preparation method of above-mentioned oil-resistant auxiliary agent comprises the steps:

[0048] (1) 50mg Ti 3 C 2 T x Ti was prepared by adding tetrahydrofuran solution with a concentration of 4 mg / mL 3 C 2 T x Dispersion, add 1.5g acrylamide and then stir, and then add a mixed solution containing 2.5g styrene, 2.5g acrylonitrile, 0.2g tert-dodecyl m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com