V2O3 and its blended nano powder and its preparing method

A nano-powder and powder technology, which is applied in the field of V2O3 and its dopant nano-powder and its preparation, can solve the problems of difficult commercialization of materials, unfavorable mass production, no preparation method, etc., and achieves low equipment requirements and investment. Small, environmentally friendly effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

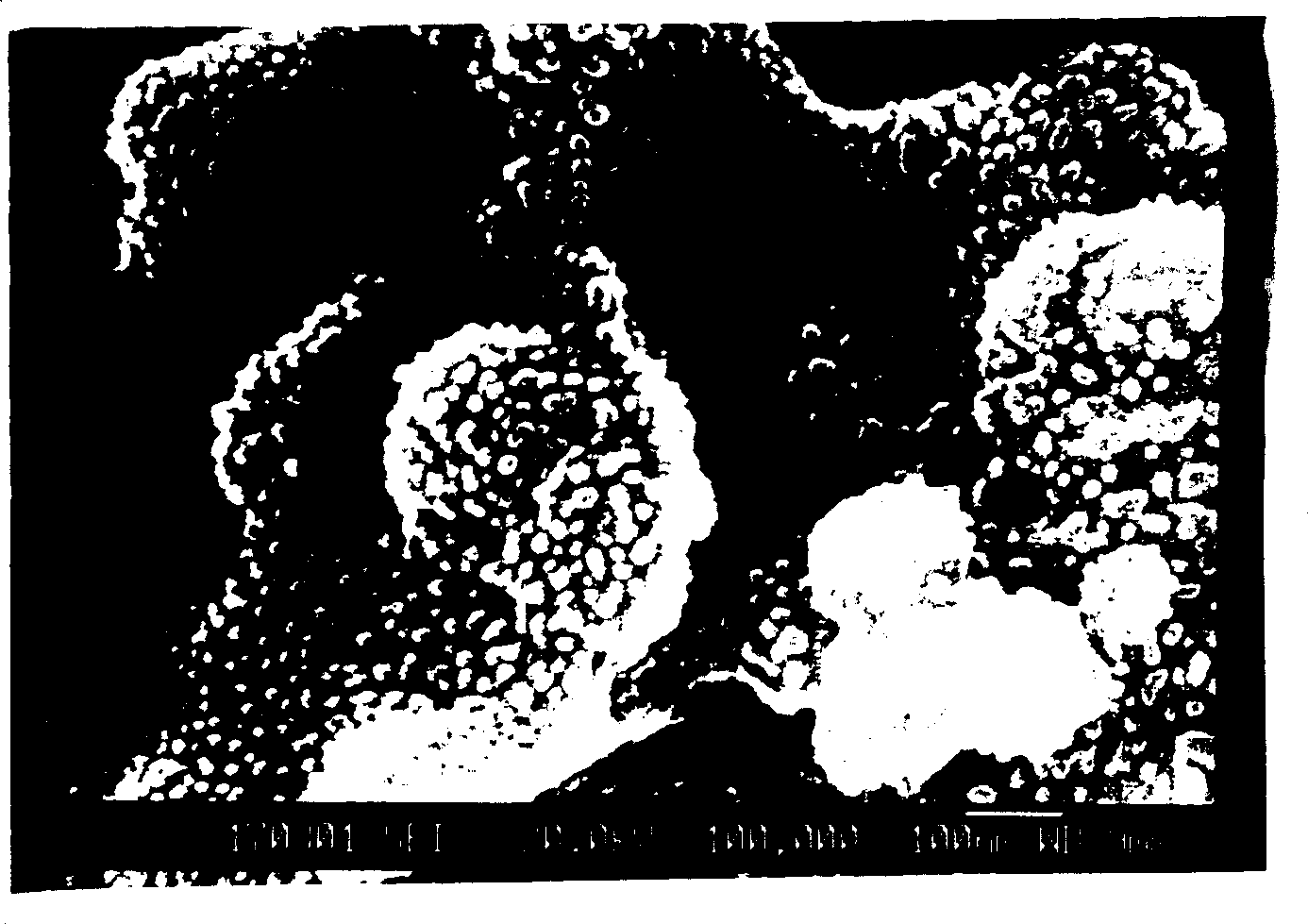

Image

Examples

Embodiment 1

[0021] V 2 o 3 Powder preparation

[0022] 1) Weigh 91gV 2 o 5 , add a small amount of distilled water to adjust the slurry, add 38gH 2 C 2 o 4 2H 2 O, heat, add 140~160ml concentrated hydrochloric acid in batches under stirring, boil slightly for 3~6 minutes, then add N 2 h 4 ·H 2 O makes the solution turn dark blue, and the reduction produces VOCl 2 solution. with a small amount of V 2 o 5 or N 2 h 4 2HCl adjusted to the solution can not detect VO 2 + and V 3+ ion. If necessary, filter to remove insoluble matter, and then dilute to 500ml;

[0023]2) Weigh 28-32g NH 4 HCO 3 or 17~20g(NH 4 ) 2 CO 3 , add a small amount of distilled water, pass CO 2 gas. Then add 56 ~ 60ml of the above VOCl under stirring z solution. Let it stand for 0.5-2 hours, or it can be placed overnight under the isolation of air. Suction filtration, with saturated NH 4 HCO 3 The solution was washed to be free of Cl - , and then washed with a small amount of ethanol to obta...

Embodiment 2

[0027] Doped with Cr 3+ Powder preparation:

[0028] In the preparation of doped Cr 3+ When the substance contains Cr 3+ salts, such as CrCl 3 and Cr 2 (SO 4 ) 3 etc. can be used as a source of dopant ions, they can be added to VOCl 2 solution, can also be added in NH 4 HCO 3 or (NH 4 ) 2 CO 3 in solution. at (V 1-x Cr x ) 2 o 3 The value of x in (0≤x≤0.04) can be adjusted by changing the molar ratio of Cr and V in the doping system, and the deviation of repeated experiments for the same value of x is 2 Add Cr to the solution 2 (SO 4 ) 3 , and then use the same method as in Example 1 to synthesize a Cr-doped precursor. Reduction of the thermally decomposed precursor in H2 gas stream, the nanopowder body composition that obtains is (V 0.988 Cr 0.012 ) 2 o 3 .

Embodiment 3

[0030] Doped with Al 3+ Powder preparation:

[0031] In the preparation of Al-doped 3+ substance, containing Al 3+ salts such as AlCl 3 and Al 2 (SO 4 ) 3 etc., can be used as a source of dopant ions. They can be added in VOCl 2 solution, can also be added in (NH 4 ) 2 CO 3 or (NH 4 )HCO 3 in solution. at (V 1-x Al x ) 2 o 3 The value of x in (0≤x≤0.03) can be determined by doping Al 3+ The variation of the molar ratio of Al and V in the system is adjusted, and the deviation of repeated experiments with the same value of x is 4 )HCO 3 AlCl was added to the solution 3 , and then use the same method as in Example 1 to synthesize the aluminum-doped precursor, and in H 2 Reductive thermal decomposition in the air stream, the composition of the obtained nano-powder is (V 0.091 Al 0.009 ) 2 o 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com