High-transparency, high-hardness and low-birefringence polycarbonate as well as preparation method and application thereof

A technology of polycarbonate and low birefringence, which is applied in the field of high transparency, high hardness and low birefringence polycarbonate and preparation, can solve the problems of materials with large shrinkage ratio, uneven monomer distribution, and affecting the use of materials, etc., to achieve Good processability, excellent light transmittance and scratch resistance, effect of excellent scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] To prepare the compound shown in formula VI (preparation of FDCP from FDCC), the molar ratio of 2,5-furandicarbonyl chloride to phenol is 1:2.2;

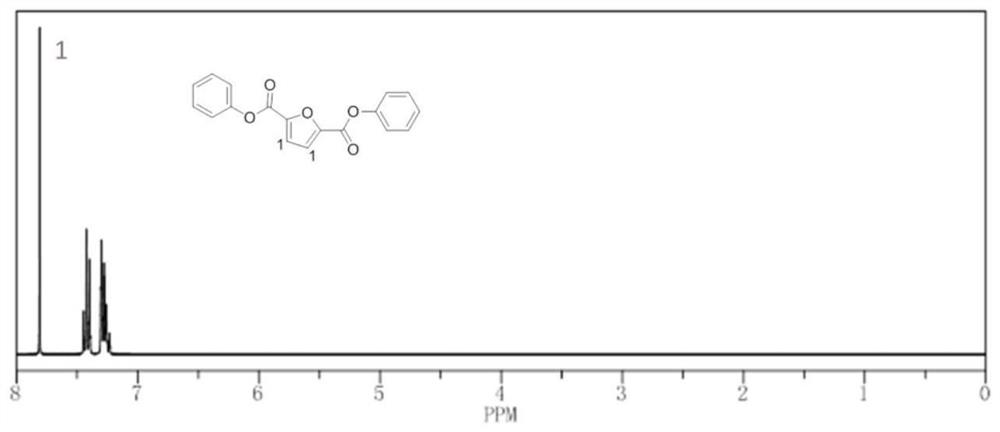

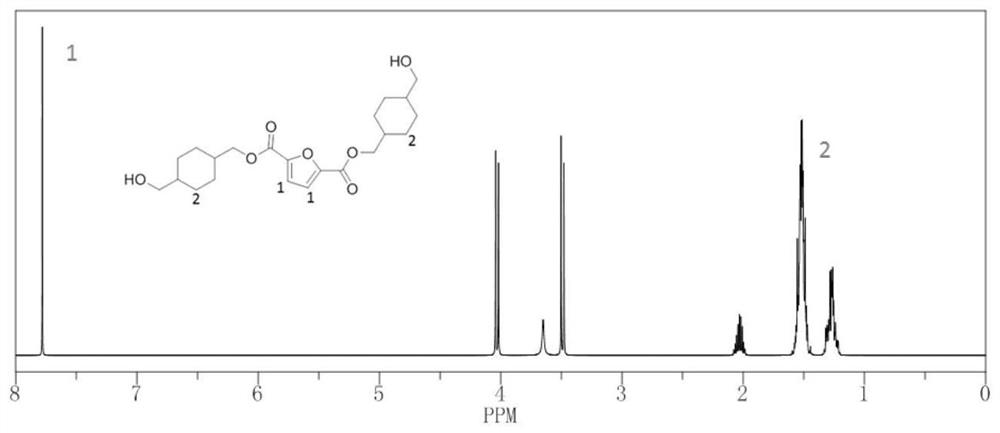

[0076] 15.609kg (80mol) of 2,5-furandicarbonyl chloride (FDCC) was dissolved in 15.609kg of methylene chloride, added to the 100L reactor equipped with a polytetrafluoroethylene stirring paddle, and 16.73kg (176mol) of phenol was added. It was dissolved in 19.76 kg of dichloromethane, and the phenol / dichloromethane solution was added dropwise to the FDCC / dichloromethane solution within 1 hour through a constant pressure feeding device. The mixture was heated to 50°C, and the dichloromethane was distilled off by feeding nitrogen with stirring to obtain a crude FDCP product. The crude FDCP product was recrystallized in ethanol, and the crystallized FDCP crystals were dried in a vacuum drying oven at 160°C for 3 hours to obtain Pure FDCP, by 1H NMR ( figure 1 ) analyze its structure as

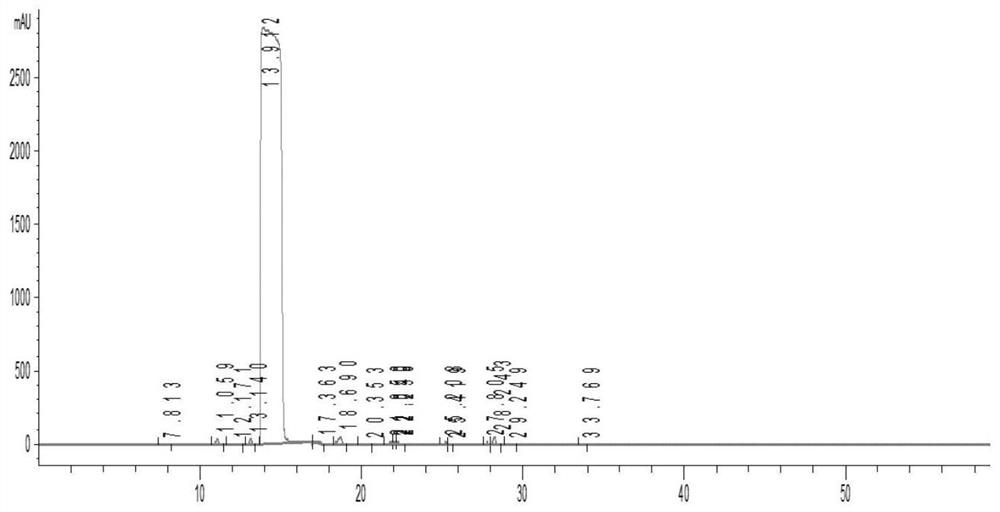

[0077] by liquid chromatography ( f...

Embodiment 2

[0079] To prepare the compound shown in formula VI (preparation of FDCP from FDCC), the molar ratio of 2,5-furandicarbonyl chloride to phenol is 1:2.5;

[0080] 15.609kg (80mol) 2,5-furandicarbonyl chloride (FDCC) was dissolved in 15.609kg monochlorobenzene, added to the 100L reactor equipped with a polytetrafluoroethylene stirring paddle, 19.00kg (202mol) Phenol was dissolved in 19.76kg of monochlorobenzene, and the phenol / monochlorobenzene solution was added dropwise to the FDCC / monochlorobenzene solution within 1 h through a constant pressure feeding device. After the reaction was completed, the mixture was heated to 50°C, and the monochlorobenzene was distilled off by feeding nitrogen with stirring to obtain a crude FDCP product. The crude FDCP product was recrystallized in ethanol, and the crystallized FDCP crystals were dried in a vacuum oven at 160°C. After drying for 3 h, pure FDCP was obtained. The structure of the FDCP was analyzed as formula (VI), and the purity was...

Embodiment 3

[0082] To prepare the compound shown in formula VI (preparation of FDCP from FDCC), the molar ratio of 2,5-furandicarbonyl chloride to phenol is 1:2.7;

[0083] 15.609kg (80mol) 2,5-furandicarbonyl chloride (FDCC) was dissolved in 15.609kg o-dichlorobenzene, added to the 100L reactor equipped with a polytetrafluoroethylene stirring paddle, 20.53kg (218mol) ) Phenol was dissolved in 19.76kg o-dichlorobenzene, and the phenol / o-dichlorobenzene solution was added dropwise to the FDCC / o-dichlorobenzene solution within 1 h through the constant pressure feeding device, and continued at 30°C after the dropwise addition was completed. The reaction was stirred for 2 h. After the reaction was completed, the mixture was heated to 50° C., and the ortho-dichlorobenzene was distilled off by introducing nitrogen gas under stirring to obtain a crude FDCP product. The crude FDCP product was recrystallized in ethanol. It was dried in a vacuum drying oven at 160° C. for 3 hours to obtain pure FDC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com