Preparation and performance detection method of coated tryptophan pellet feed

A pellet feed and tryptophan technology, applied in the granulation method of raw materials, animal feed, microsphere preparation, etc., can solve the problems of reduced efficiency, increased workload of animal breeding, etc., and achieve improved production performance and good use effect , the effect of promoting utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

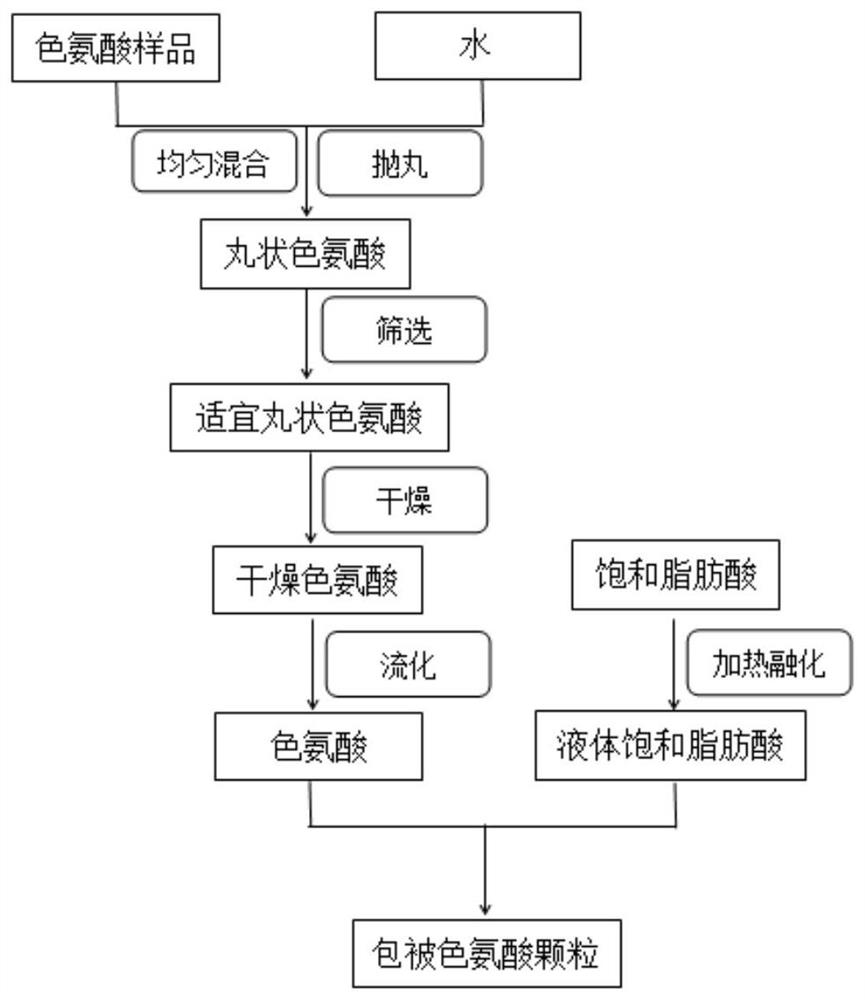

[0033] A preparation method of coated tryptophan pellet feed, comprising the following steps:

[0034] Step 1: Core material preparation

[0035] Mix 30kg of L-tryptophan with 1kg of water and then carry out shot blasting to 1.5mm spherical particles.

[0036] Step 2: Mix and Dry

[0037] The drying temperature is 50° C., and drying is performed for 80 minutes, and the dried tryptophan pellets are obtained when the moisture content is less than or equal to 10 wt %.

[0038] Step 3: Fluidize

[0039] Pour the dried tryptophan pellets into the storage tank of the fluidized bed, adjust the air pressure of the fluidized bed to 0.01 MPa, the rotational speed to 90 r / min, the air inlet temperature to be 35 °C, and the air outlet temperature to be 25 °C.

[0040] Step 4: Wall Material Preparation

[0041] After melting 30 kg of C16-C18 fatty acids, it was cooled to 55°C.

[0042] Step 5: Coating

[0043] Mix the core material and the wall material with a weight ratio of 1:1 to ...

Embodiment 2

[0045] Different from above-mentioned embodiment 1, a kind of preparation method of coated tryptophan pellet feed comprises the following steps:

[0046] Step 1: Core material preparation

[0047] Mix 30kg of L-tryptophan and 1kg of water, and then carry out shot blasting treatment to 3mm spherical particles.

[0048] Step 2: Sieve

[0049] Spherical particles less than 3mm in diameter were rejected.

[0050] Step 3: Mix and Dry

[0051] The drying temperature is 70° C., and drying is performed for 50 minutes, and when the moisture content is less than or equal to 10 wt %, the dried tryptophan pellets are obtained.

[0052] Step 4: Fluidize

[0053] Pour the dried tryptophan pellets into the storage tank of the fluidized bed, adjust the air pressure of the fluidized bed to 0.024MPa, the rotation speed is 100r / min, the air inlet temperature is 45°C, and the air outlet temperature is 35°C.

[0054] Step 5: Wall Material Preparation

[0055] After melting 60 kg of hydrogenate...

Embodiment 3

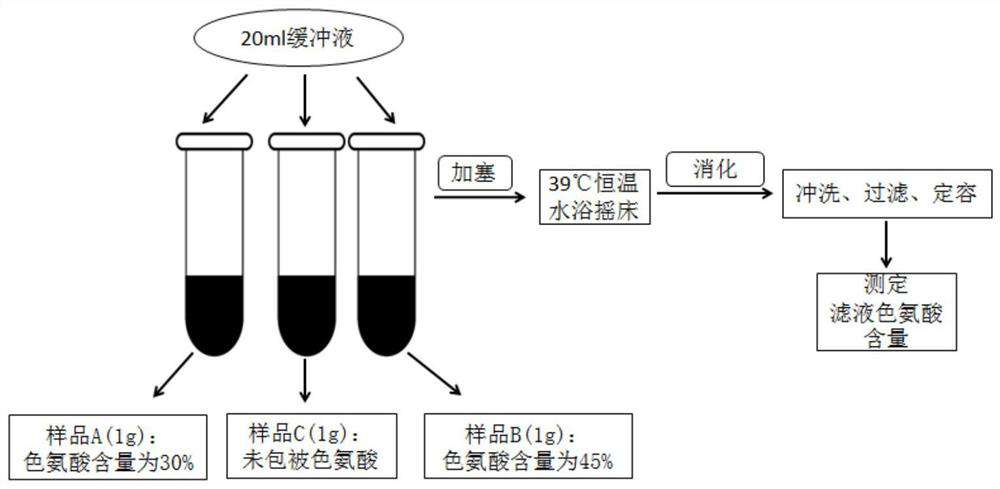

[0059] A method for testing the performance of a tryptophan-coated pellet feed adopts an in vitro simulated digestive tract test, and the specific operation method is as follows:

[0060] Step 1: Test Materials

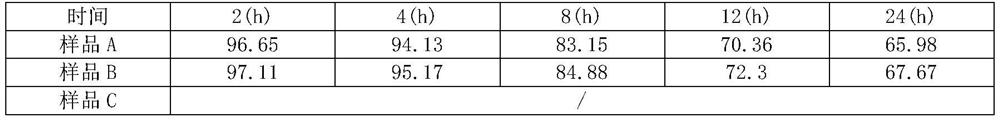

[0061] pH 6.6 buffer and pH 2.4 buffer, pH 6.6 buffer was used to simulate the rumen environment of ruminants, and pH 2.4 buffer was used to simulate the duodenal environment of ruminants. Coated tryptophan samples A and B, in which the mass percentage of tryptophan was 30% and 45% respectively, and uncoated tryptophan sample C.

[0062] Step 2: Test Method

[0063] For the stability test in different pH buffers, the uncoated tryptophan was used as the control group, and 1 g each of samples A, B, and C were weighed, placed at the bottom of a 50 ml stoppered test tube, 20 ml of buffer was added, and the test tube was tightly capped Stopped; digested in a constant temperature water bath shaker at 39°C for 2h, 4h, 8h, 12h and 24h; after taking out, rinsed, filtered, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com