Degradable PBAT polymer regenerated from waste PBT and preparation and application thereof

A polymer and polycondensation reaction technology, applied in the direction of one-component polyester rayon, adhesives, etc., can solve the problems of difficulty in large-scale promotion and application, affecting product quality, and difficulty in polymerization, so as to solve the problem of single recycling and reproducing, and realize the Low-carbon and green use of the environment and the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

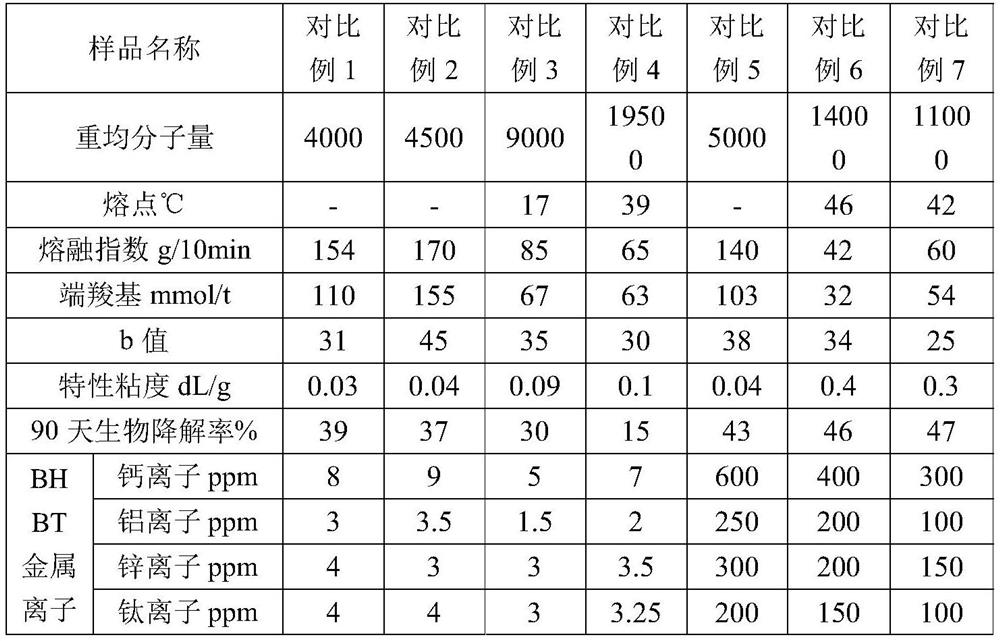

Embodiment 1

[0057] A preparation method for regenerating waste PBT into degradable PBAT polymer, the concrete steps are as follows:

[0058] (1) Treatment of waste PBT: The waste PBT material derived from the scraps of injection molding parts for vehicles is processed to obtain PBT powder with a particle size of less than 2 mm, and then sieved. Finally, the PBT powder is placed in a vacuum oven at 100 ° C for drying for 12 hours ;

[0059] (2) Preparation of the regenerated monomer BHBT: take the dried PBT powder, 1,4-butanediol, catalyst, anti-aging agent and anti-ether agent in step (1) and add it to the reaction kettle, pass nitrogen protection , dissolve at 180 °C, gradually heat up to 220 °C after the system is clarified, and keep this temperature for 1.8h reaction; record the water output, when it reaches 90% of the theoretical value, it can be evacuated, and the vacuum degree of the control system is 1000Pa, and the control time is 30min; Then add a complexing agent, react after 1...

Embodiment 2

[0079] A preparation method for regenerating waste PBT into degradable PBAT polymer, the concrete steps are as follows:

[0080] (1) Treatment of waste PBT: The waste PBT material derived from the scraps of injection molding parts for vehicles is processed to obtain PBT powder with a particle size of less than 2 mm, and then sieved. Finally, the PBT powder is placed in a vacuum oven at 120 ° C for drying for 8 hours ;

[0081] (2) Preparation of the regenerated monomer BHBT: take the dried PBT powder, 1,4-butanediol, catalyst, anti-aging agent and anti-ether agent in step (1) and add it to the reaction kettle, pass nitrogen protection , dissolve at 195 ℃, gradually heat up to 230 ℃ after the system is clarified, keep this temperature for 2h reaction; record the water output, when it reaches 90% of the theoretical value, it can be evacuated, the vacuum degree of the control system is 500Pa, and the control time is 20min; then Add complexing agent, react after 15min, filter unr...

Embodiment 3

[0101] A preparation method for regenerating waste PBT into degradable PBAT polymer, the concrete steps are as follows:

[0102] (1) Treatment of waste PBT: The waste PBT material derived from textile scraps is processed to obtain PBT powder with a particle size of less than 2 mm, and then sieved, and finally the PBT powder is placed in a vacuum oven at 110 ° C for drying for 6h;

[0103] (2) Preparation of the regenerated monomer BHBT: take the dried PBT powder, 1,4-butanediol, catalyst, anti-aging agent and anti-ether agent in step (1) and add it to the reaction kettle, pass nitrogen protection , dissolve at 200 ℃, gradually heat up to 210 ℃ after the system is clarified, keep this temperature for 1.5h reaction; record the water output, when it reaches 90% of the theoretical value, it can be evacuated, the vacuum degree of the control system is 100Pa, and the control time is 45min; Then add a complexing agent, react after 18min, filter the unreacted material while hot to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com