Cr3Te4 non-layered two-dimensional material and preparation and application thereof

A two-dimensional material, non-layered technology, applied in the field of nanomaterials, can solve the problems of limited performance exploration and inability to obtain two-dimensionality, and achieve the effects of good crystallinity, good shape, and excellent air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

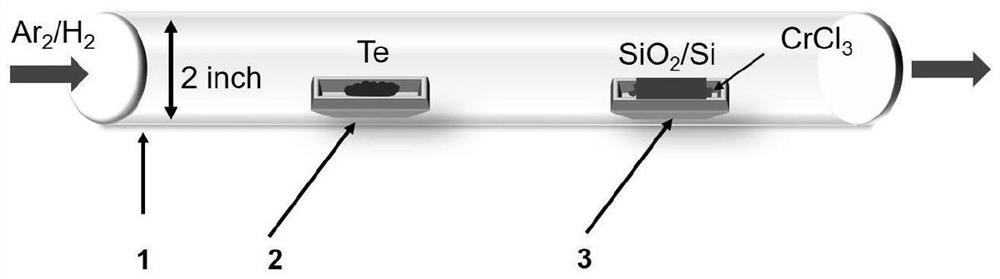

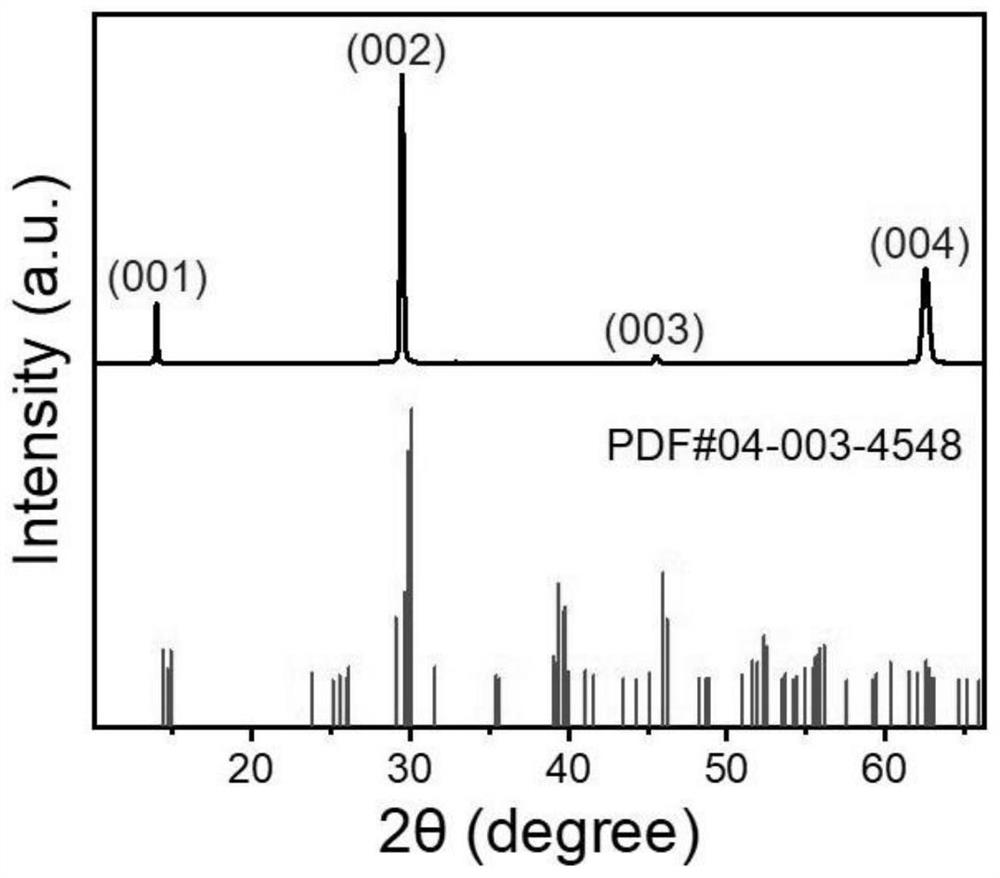

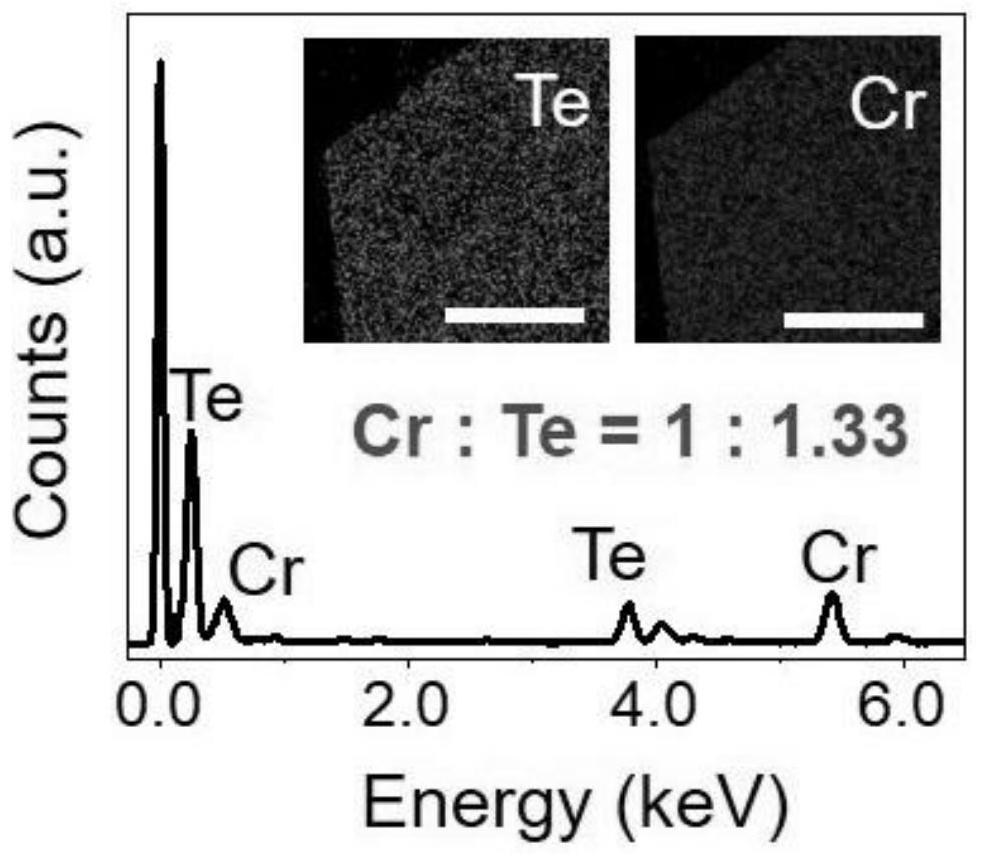

[0106] Cr 3 Te 4 Preparation of nanosheets:

[0107] Put the porcelain boat filled with Te powder in the constant temperature zone upstream of the tube furnace (the temperature is 630℃, which is the volatilization temperature of Te powder), and it is filled with CrCl 3 and the deposition surface faces CrCl 3 placed silicon wafers (285nm SiO 2 / Si substrate) the porcelain boat is placed in the center of the downstream constant temperature zone (temperature is 680℃; CrCl 3 volatilization and deposition temperature). CrCl 3 The mass ratio of powder and Te powder was 1:1 (0.05g / 0.05g). Before heating, purge the air in the quartz tube with a large flow of argon. Then, the constant temperature zones 2 and 3 are heated to 630°C (Te powder volatilization temperature) and 680°C (CrCl 3 volatilization and deposition temperature), and the flow rate of the argon-hydrogen mixture was 40 / 15 sccm, and the temperature was kept constant for 5 min. There will be single crystal Cr on th...

Embodiment 2

[0110] Compared with Example 1, the difference is only that the weight ratio of chromium trichloride and Te is adjusted, respectively: (A): the weight ratio of chromium trichloride and Te is 3:1; (B): trichloride The weight ratio of chromium and Te is 2:1; other preparation processes such as raw material volatilization temperature, deposition temperature, carrier gas and the consumption of Te are the same as in Example 1. The optical image of the prepared product is shown in Image 6 (Scale bar is 10 μm).

[0111] The experimental results of group A can be found in Image 6 a, The product is a nanosheet with a large thickness (about 30-40nm), and there is a certain amount of chromium trichloride deposition on the surface of the substrate (blue substance on the substrate), which makes the material prone to deliquescence and affects the crystal quality. The experimental results of group B can be found in Image 6 b, Cr 3 Te 4 Growth has improved significantly, Cr 3 Te 4 T...

Embodiment 3

[0113] Compared with Example 1, the only difference is that the temperature at which Te volatilizes is adjusted, which are: (A): 600°C; (B): 640°C; (C): 670°C; (D): 570°C; (E) ): 700°C (F): 720°C; other steps and parameters are the same as in Example 1. For optical pictures under each condition see Figure 7 .

[0114] Figure 7 a-c are Cr grown in the preferred range (600-670°C range) by controlling the volatilization temperature of Te 3 Te 4 The optical picture of the nanosheets shows that the thickness of the nanosheets basically increases with the increase of the volatilization temperature of Te, and the synthesized nanosheets have regular shapes, clean surfaces and high crystal quality. Figure 7 d-f is the volatilization temperature of other Te. It is found that when the volatilization temperature of Te is low, due to insufficient supply of Te, the nanosheets will generate more lattice defects of Te during the growth process, resulting in poor crystal quality. high ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com