Composite lithium supplement additive and lithium ion battery positive electrode lithium supplement method

An additive and lithium-replenishing technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as generating more oxygen, affecting battery safety and stability, and performance degradation, avoiding safety risks and achieving cycle stability. , the effect of high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

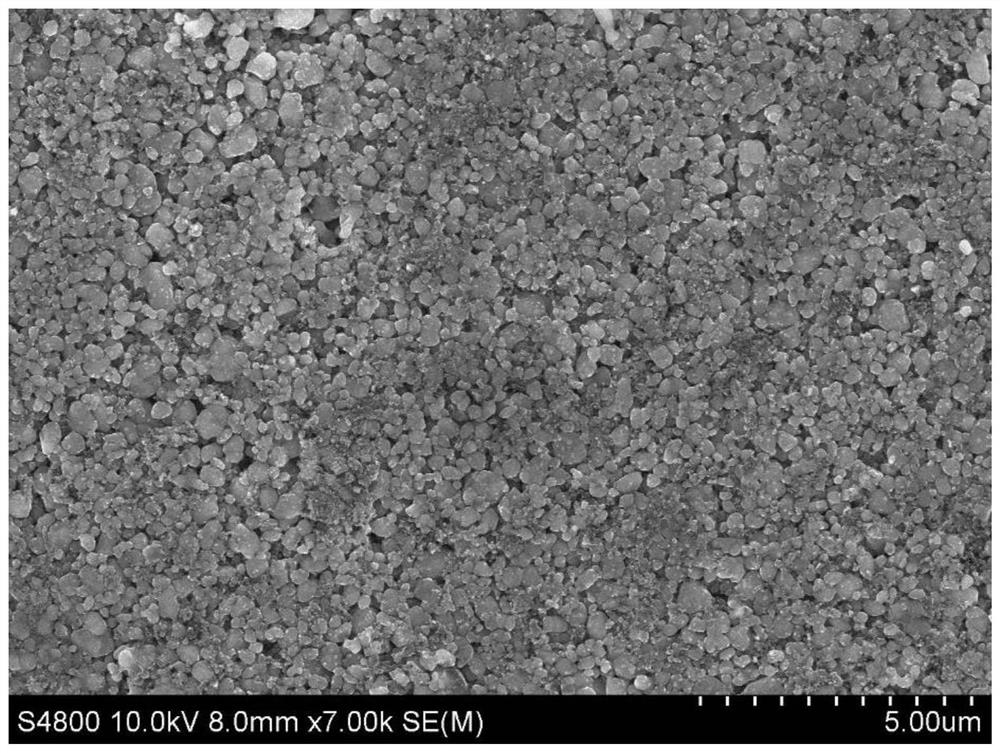

[0058] 1) Ball Milling Lithium Additive Lithium 5 FeO 4 To particle size less than 100nm;

[0059] 2) To 84mg triphenylphosphine and 450mg Li 5 FeO 4 50 mL of chloroform was added to the powder, stirred for 4 h, and the solvent was evaporated at 80° C. to obtain a composite lithium-supplementing additive (N=1); the molar fraction of phosphorus in the composite lithium-supplementing additive was 10%;

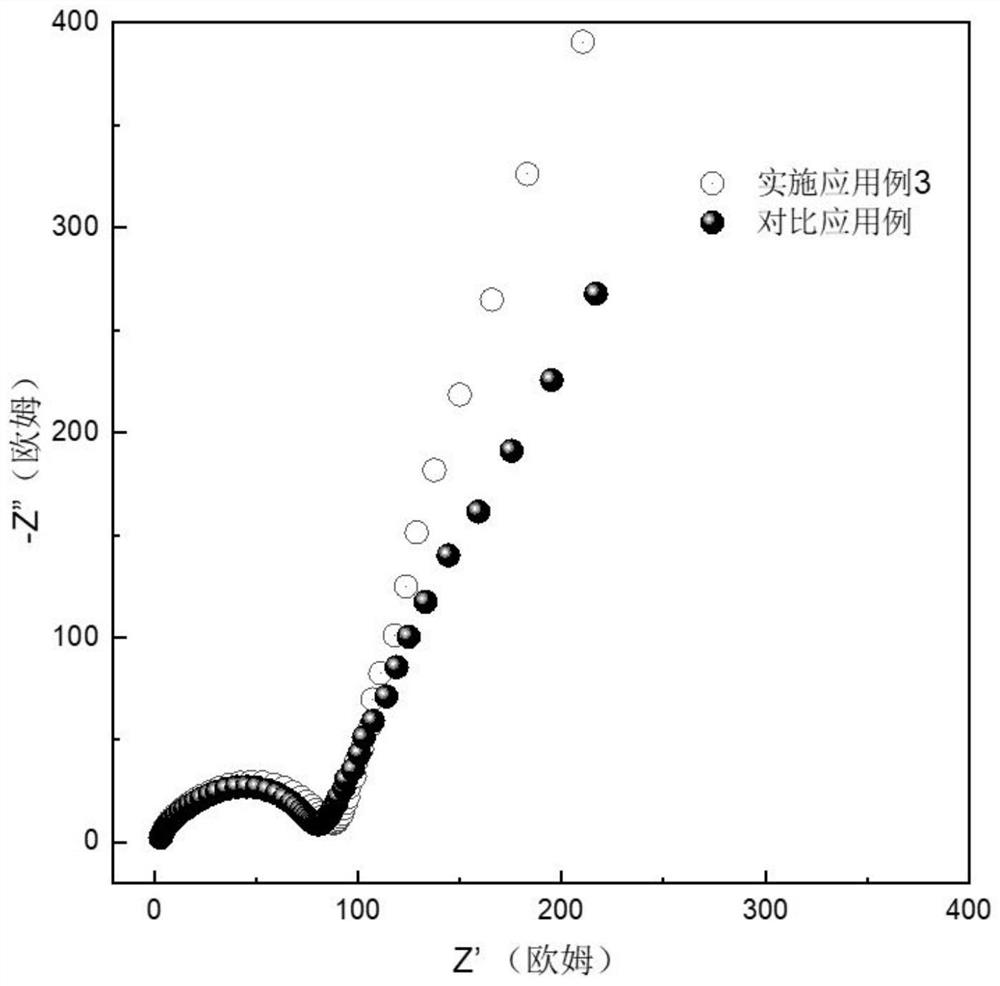

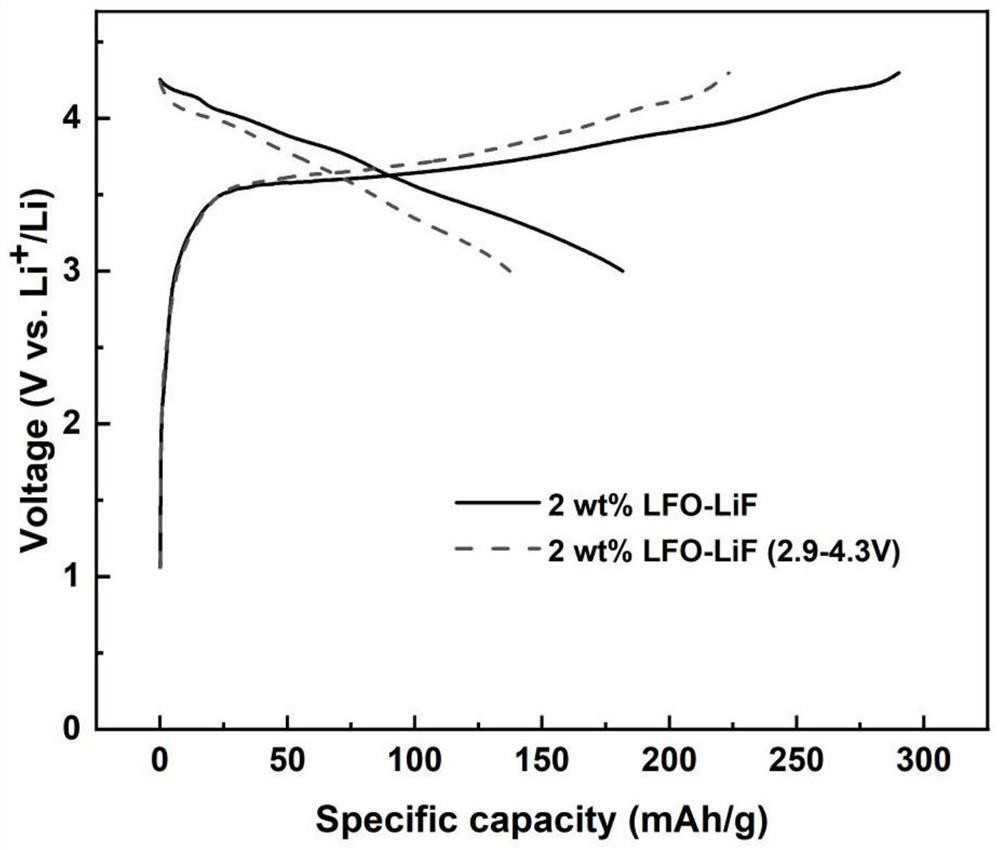

[0060] 3) The nickel cobalt lithium manganate LiNi 0.8 Co 0.1 Mn 0.1 O 2 (NCM811), carbon black and binder (PVDF) were mixed in a mass ratio of 90:5:5, and a composite lithium-supplementing additive with an active material mass fraction of 2wt% was added to make a slurry, and the slurry was uniformly coated on the carbon-coated aluminum foil set. On the fluid, it was dried by blasting at 70 °C and then dried in a vacuum oven at 80 °C for 8 hours to prepare a positive electrode sheet with both lithium supplementation and stable cycling.

Embodiment 2

[0062] The rest are the same as in Example 1, except that the content of the composite lithium supplementing additive in the positive electrode is 5 wt %.

Embodiment 3

[0064] The rest are the same as in Example 2, except that the content of the composite lithium-supplementing additive in the positive electrode is 10 wt %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com