Infant formula liquid milk and preparation method thereof

A technology for infant formula and liquid milk, applied in the direction of milk preparations, dairy products, applications, etc., can solve the problems of fewer types of colloids, affecting the shelf-life stability of infant formula liquid milk, and whether there is any impact on infant health. Achieve the effects of improving stability, ensuring safety, and extending shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In another typical embodiment of the present application, a method for preparing any one of the above-mentioned infant formula liquid milk is provided, the preparation method comprising: step S1, mixing raw materials of infant formula liquid milk to form a premix milk; step S2, heating the premixed milk to 55-80° C. and then homogenizing it at 35-60 MPa to obtain liquid milk; step S3, sterilizing the liquid milk to obtain infant formula liquid milk.

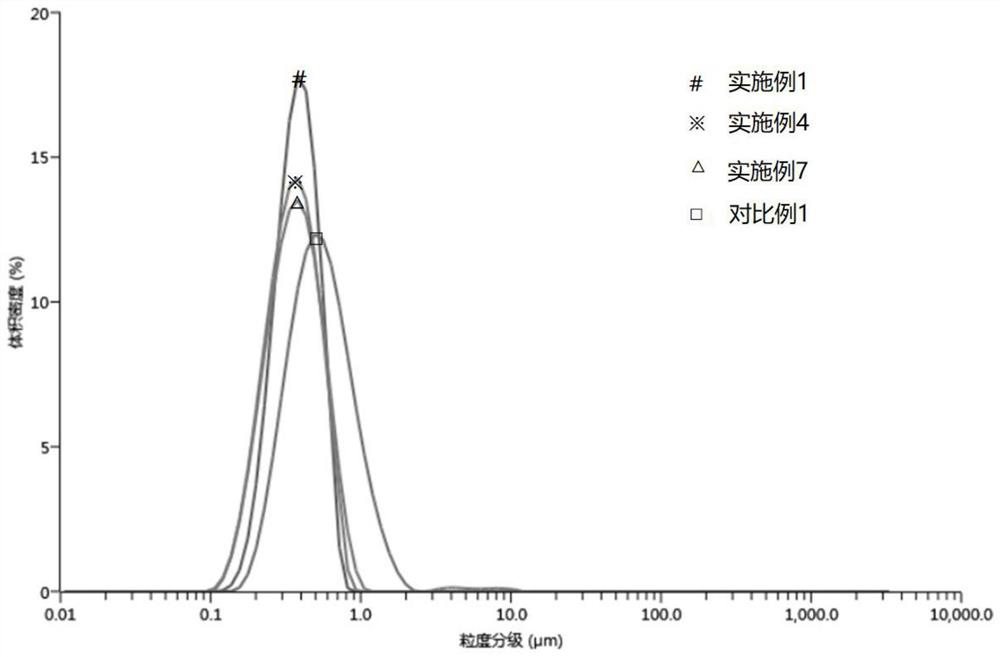

[0028] The infant formula liquid milk of the present application adopts phospholipids and mono- and diglycerol fatty acid esters as emulsifiers, which avoids the use of gum emulsifiers and ensures the safety of the liquid milk for infant products; The main factor for stability is the stratification caused by fat agglomeration; the purpose of homogenization is to make dairy products have a uniform structure, and its main function is to split the larger fat globules in natural milk into smaller fat globules, which can To del...

Embodiment 1

[0035] Taking producing 1 ton of product of the present invention as an example, its formula is composed as follows:

[0036] Raw milk 200kg, whey protein powder 52kg, lactose 15kg, vegetable oil 24kg, mono- and diglycerol palmitate 0.5kg, phospholipid 1.5kg, galactooligosaccharide 8kg, docosahexaenoic acid oil 0.3kg, compound mineral Substance 0.4kg, compound vitamin 1kg, arachidonic acid oil 0.3kg, choline chloride 0.06kg, calcium carbonate 1kg, sodium citrate 0.5kg, potassium chloride 0.4kg, dipotassium hydrogen phosphate 0.35kg, the rest are water .

[0037] The mass proportion of each monomer vegetable oil in the vegetable oil: 1,3-dioleic acid 2-palmitic acid triglyceride: sunflower oil: walnut oil: linseed oil = 73.23:20.59:3.32:2.86, 1,3-di The sn-2 palmitic acid of oleic 2-palmitic acid triglyceride accounts for 67% of the total palmitic acid content, and the sn-2 palmitic acid in the fatty acid of infant formula liquid milk accounts for about 53% of the total palmit...

Embodiment 2

[0042] Taking producing 1 ton of product of the present invention as an example, its formula is composed as follows:

[0043] Raw milk 200kg, whey protein powder 52kg, lactose 15kg, vegetable oil 24kg, mono- and diglycerol palmitate 1kg, phospholipid 1kg, galactooligosaccharide 8kg, docosahexaenoic acid oil 0.3kg, compound mineral 0.4 kg, compound vitamin 1kg, arachidonic acid oil 0.3kg, choline chloride 0.06kg, calcium carbonate 1kg, sodium citrate 0.5kg, potassium chloride 0.4kg, dipotassium hydrogen phosphate 0.35kg, and the rest are water.

[0044] The mass proportion of each monomer vegetable oil in the vegetable oil: 1,3-dioleic acid 2-palmitic acid triglyceride: sunflower oil: walnut oil: linseed oil = 73.23:20.59:3.32:2.86, 1,3-di The sn-2 palmitic acid of oleic 2-palmitic acid triglyceride accounts for 67% of the total palmitic acid content, and the sn-2 palmitic acid in the fatty acid of infant formula liquid milk accounts for about 53% of the total palmitic acid con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com