Catalyst for preparing m-xylylenediamine through hydrogenation of isophthalonitrile as well as preparation method and application of catalyst

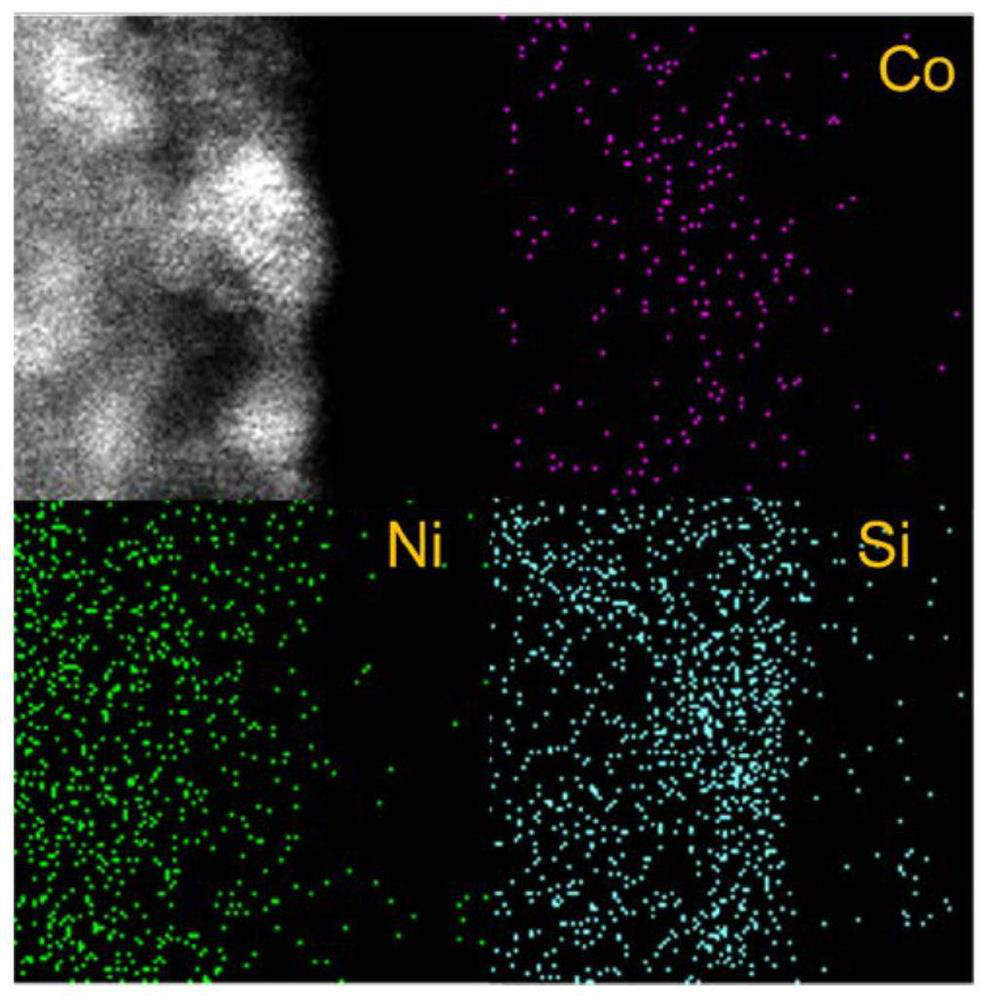

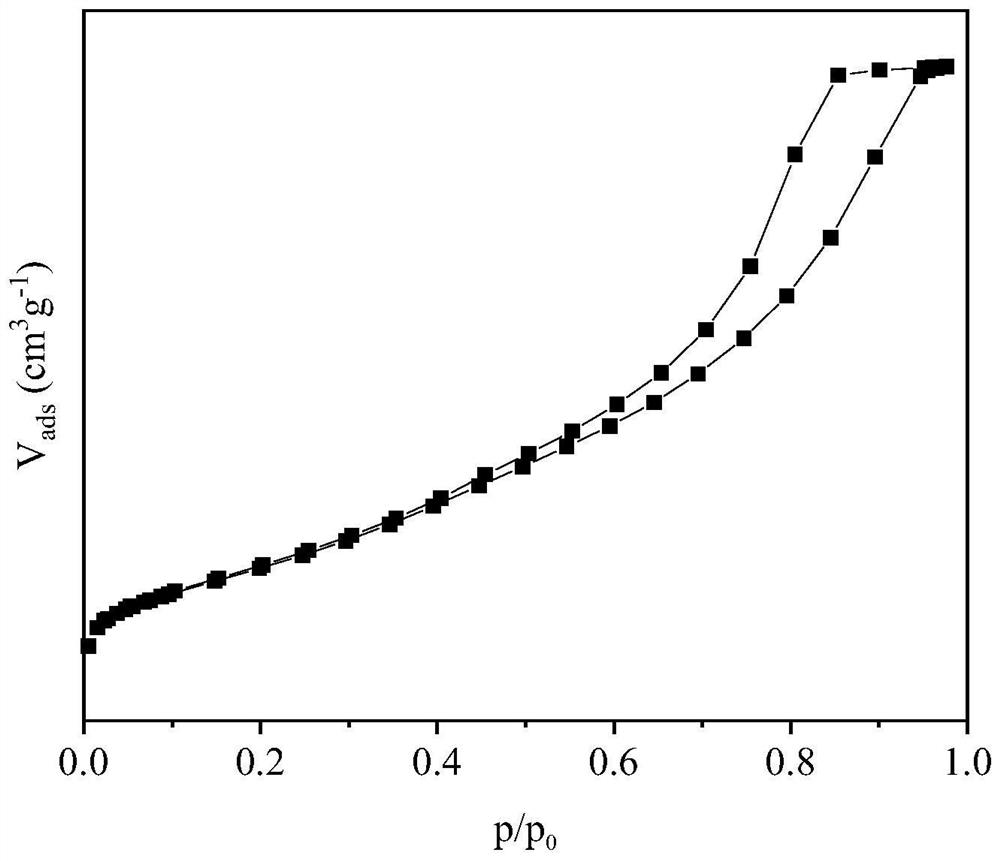

A technology of isophthalonitrile and m-xylylenediamine, which is applied in the field of catalysts for preparing m-xylylenediamine by hydrogenation of isophthalonitrile and its preparation field, can solve the problems of lack of catalyst stability, unfavorable continuous operation, Exploring and other issues to achieve the effect of avoiding efficiency reduction, high specific surface area, and large pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

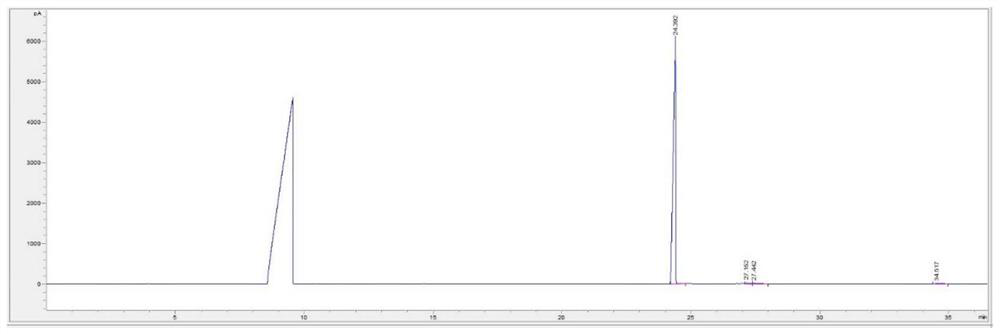

Examples

Embodiment 1

[0058] 1) dissolving nickel nitrate with deionized water, wherein, the concentration of nickel ions in the solution is 0.5M, and the solution volume is 75mL;

[0059] 2) Weighing citric acid and adding it to the solution of step 1), stirring into a homogeneous solution, wherein the pH value of the solution is 5;

[0060] 3) Weigh 10 grams of aluminum sol and add it to the solution in step 2), stir at room temperature for 2 hours, then heat up to 90°C and stir for 1 hour;

[0061] 4) dissolving cobalt nitrate with deionized water, wherein the concentration of cobalt ions in the solution is 0.1M, and the solution volume is 100mL;

[0062] 5) measure a certain amount of hydrazine hydrate and add it to the solution of step 4), stir into a homogeneous solution, wherein the mol ratio of hydrazine hydrate and cobalt ion is 4:1;

[0063] 6) adding the solution of step 5) to the solution of step 3), stirring and mixing for 4 hours;

[0064] 7) The solution obtained in step 6) was the...

Embodiment 2

[0068] 1) dissolving nickel nitrate with deionized water, wherein, the concentration of nickel ions in the solution is 0.5M, and the solution volume is 75mL;

[0069] 2) Weighing citric acid and adding it to the solution of step 1), stirring into a homogeneous solution, wherein the pH value of the solution is 5;

[0070] 3) Weigh 10 grams of aluminum sol and add it to the solution in step 2), stir at room temperature for 2 hours, then heat up to 90°C and stir for 1 hour;

[0071] 4) dissolving cobalt nitrate with deionized water, wherein the concentration of cobalt ions in the solution is 0.2M, and the solution volume is 75mL;

[0072] 5) measure a certain amount of hydrazine hydrate and add it to the solution of step 4), stir into a homogeneous solution, wherein the mol ratio of hydrazine hydrate and cobalt ion is 4:1;

[0073] 6) adding the solution of step 5) to the solution of step 3), stirring and mixing for 4 hours;

[0074] 7) The solution obtained in step 6) was then...

Embodiment 3

[0078] 1) dissolving nickel nitrate with deionized water, wherein, the concentration of nickel ions in the solution is 0.4M, and the solution volume is 100mL;

[0079] 2) Weighing citric acid and adding it to the solution of step 1), stirring into a homogeneous solution, wherein the pH value of the solution is 5;

[0080] 3) Weigh 10 grams of aluminum sol and add it to the solution in step 2), stir at room temperature for 2 hours, then heat up to 90°C and stir for 1 hour;

[0081] 4) dissolving cobalt nitrate with deionized water, wherein the concentration of cobalt ions in the solution is 0.3M, and the solution volume is 50mL;

[0082] 5) measure a certain amount of hydrazine hydrate and add it to the solution of step 4), stir into a homogeneous solution, wherein the mol ratio of hydrazine hydrate and cobalt ion is 4:1;

[0083] 6) adding the solution of step 5) to the solution of step 3), stirring and mixing for 4 hours;

[0084] 7) The solution obtained in step 6) was the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com