Low-temperature cracked glaze ceramic product and manufacturing method thereof

A low-temperature cracking technology for ceramic products, applied in the field of ceramics, can solve the problems of unstable glaze effect, low ceramic strength, and single glaze effect, and achieve the effects of shortening drying time, reducing drying shrinkage and deformation, and improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

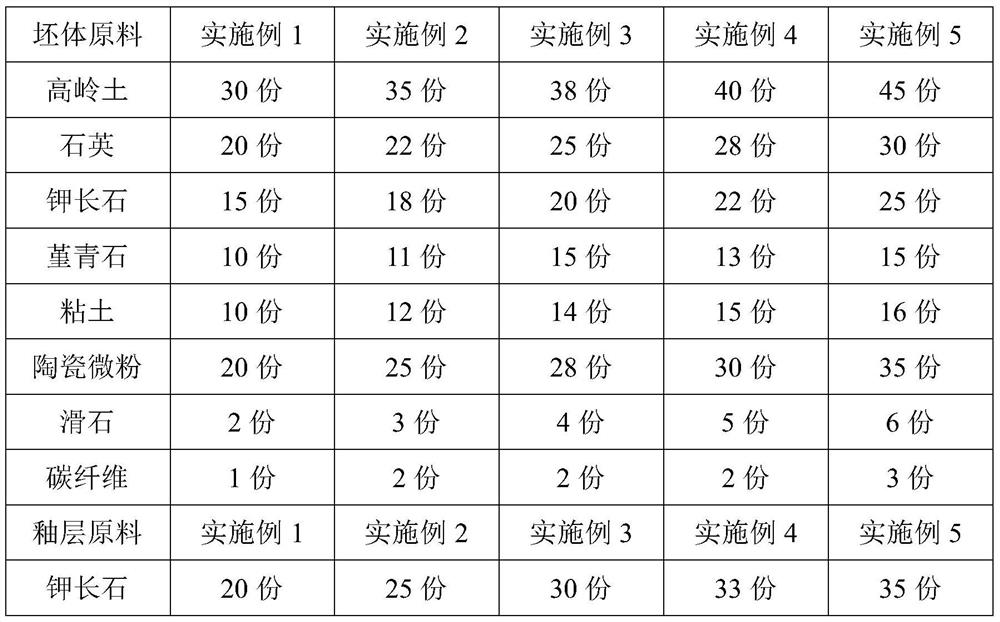

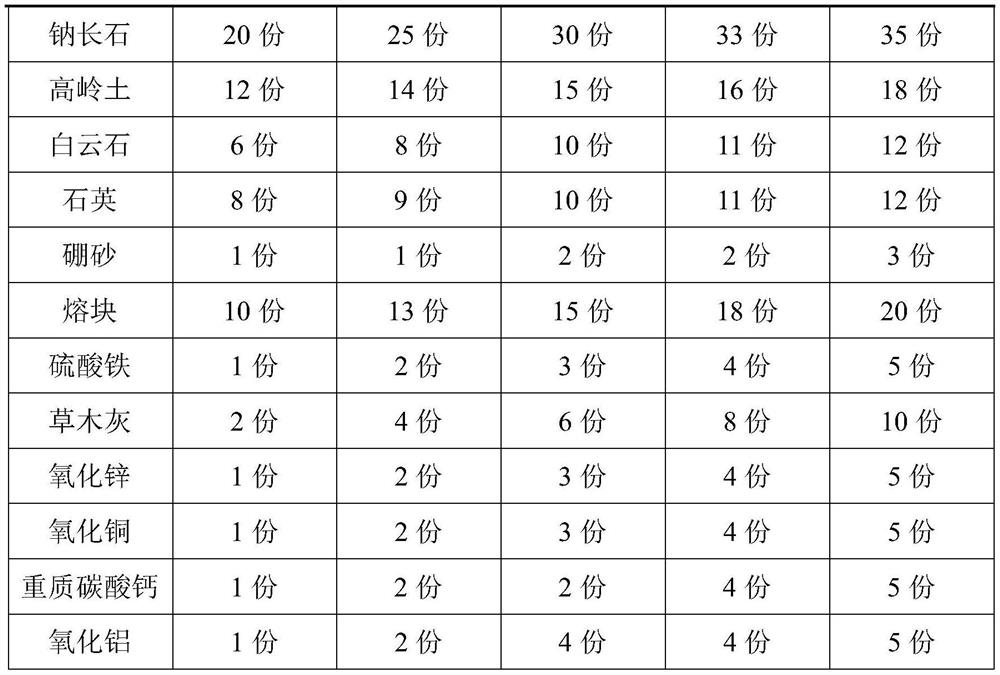

[0032] The present embodiment provides a low-temperature cracked glaze ceramic product, including a tire material and a glaze,

[0033] The tire material comprises the following raw materials in parts by weight: 30 parts of kaolin, 20 parts of quartz, 15 parts of potassium feldspar, 10 parts of cordierite, 10 parts of clay, 2 parts of talc, 1 part of carbon fiber, and 20 parts of ceramic micropowder; the glaze Including the following raw materials in parts by weight: 20 parts of potassium feldspar, 20 parts of albite, 12 parts of kaolin, 6 parts of dolomite, 8 parts of quartz, 1 part of borax, 10 parts of frit, 1 part of iron sulfate, and 2 parts of plant ash; The frit includes the following raw materials: 1 part of alumina, 1 part of zinc oxide, 1 part of copper oxide, and 1 part of heavy calcium carbonate.

[0034] Step 1. Weigh the tire material except carbon fiber according to the weight ratio and crush it, put it into a ball mill and add water for wet grinding, the wet-mi...

Embodiment 2

[0041] The present embodiment provides a low-temperature cracked glaze ceramic product, including a tire material and a glaze,

[0042] The tire material comprises the following raw materials in parts by weight: 35 parts of kaolin, 22 parts of quartz, 18 parts of potassium feldspar, 11 parts of cordierite, 12 parts of clay, 3 parts of talc, 2 parts of carbon fiber, 25 parts of ceramic micropowder; the glaze Including the following raw materials in parts by weight: 25 parts of potassium feldspar, 25 parts of albite, 14 parts of kaolin, 8 parts of dolomite, 9 parts of quartz, 1 part of borax, 13 parts of frit, 2 parts of iron sulfate, and 4 parts of plant ash; The frit includes the following raw materials: 2 parts alumina, 2 parts zinc oxide, 2 parts copper oxide, and 2 parts heavy calcium carbonate.

[0043] Step 1. Weigh the tire material except carbon fiber according to the weight ratio and crush it, put it into a ball mill and add water for wet grinding, the wet-milled slurr...

Embodiment 3

[0050] The present embodiment provides a low-temperature cracked glaze ceramic product, including a tire material and a glaze,

[0051] The tire material comprises the following raw materials in parts by weight: 38 parts of kaolin, 25 parts of quartz, 20 parts of potassium feldspar, 15 parts of cordierite, 14 parts of clay, 4 parts of talc, 2 parts of carbon fiber, and 28 parts of ceramic micropowder; the glaze Including the following raw materials in parts by weight: 30 parts of potassium feldspar, 30 parts of albite, 15 parts of kaolin, 10 parts of dolomite, 10 parts of quartz, 2 parts of borax, 15 parts of frit, 3 parts of iron sulfate, and 6 parts of plant ash; The frit includes the following raw materials: 4 parts of alumina, 3 parts of zinc oxide, 3 parts of copper oxide, and 2 parts of heavy calcium carbonate.

[0052] Step 1. Weigh the tire material except carbon fiber according to the weight ratio and crush it, put it into a ball mill and add water for wet grinding, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com