Preparation method and application of high-entropy Prussian blue sodium ion battery positive electrode material

A sodium-ion battery and Prussian blue technology, which is applied in the field of preparation of cathode materials for high-entropy Prussian blue sodium-ion batteries, can solve problems such as difficulty in comprehensively improving battery cycle stability, and achieve improved charge-discharge specific capacity and reaction, and stable crystal structure. The effect of improving the property and stabilizing the crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

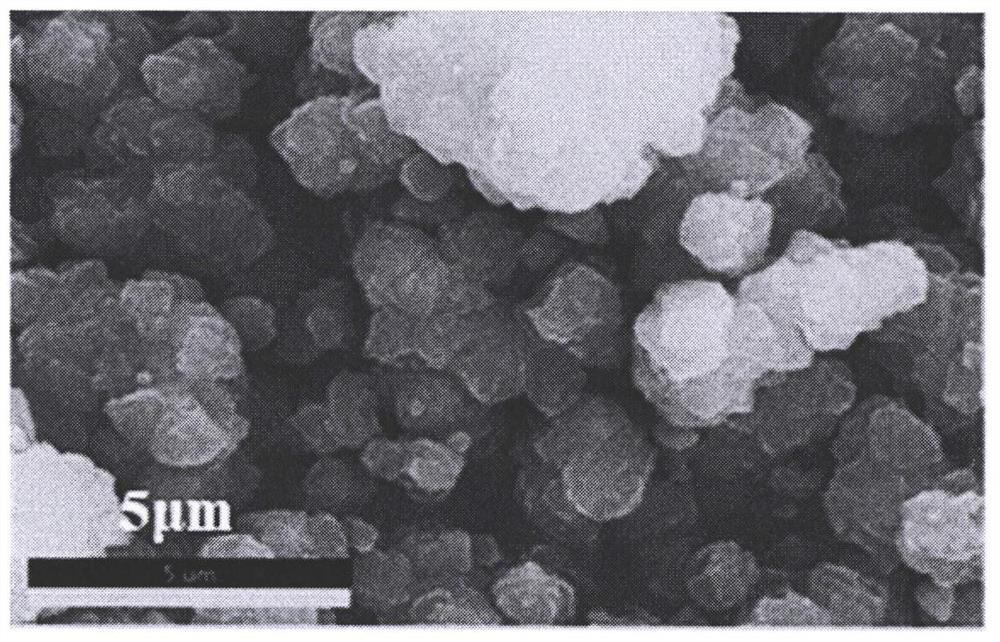

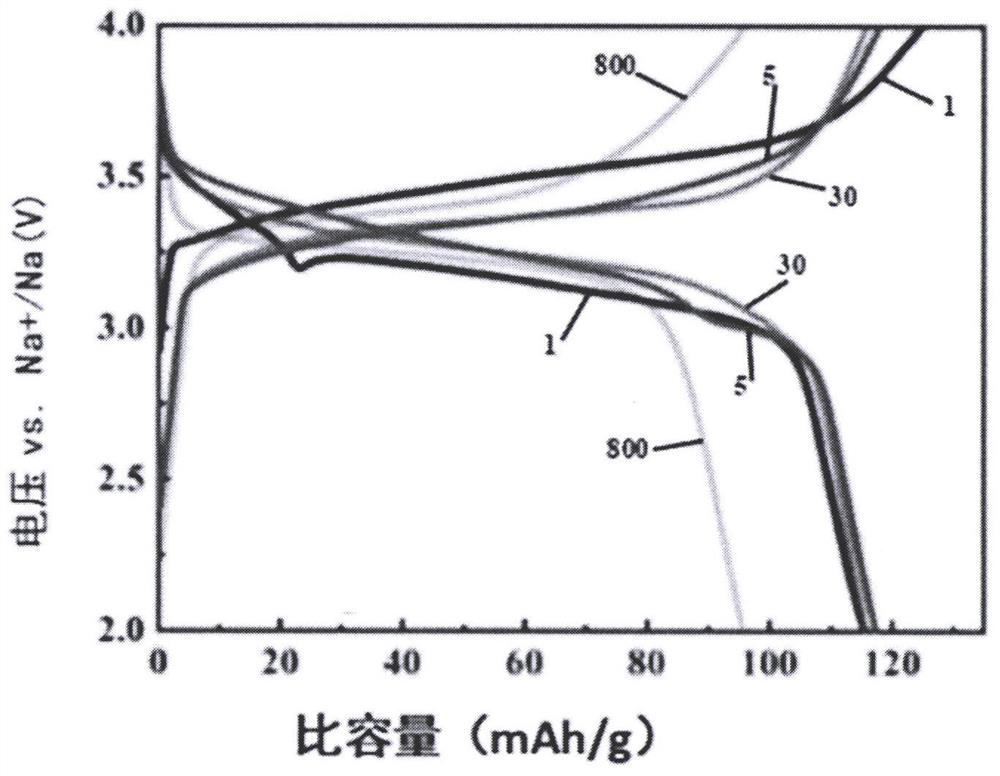

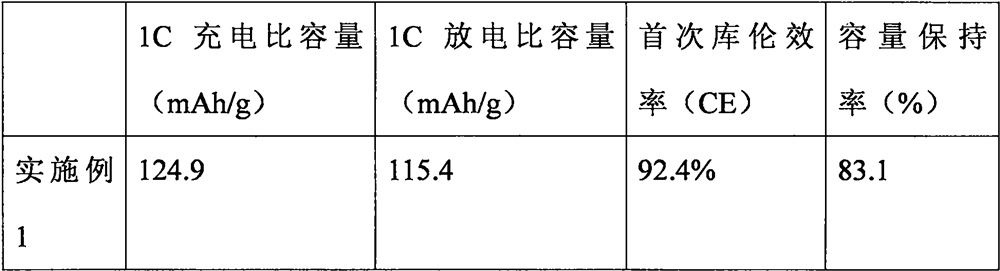

[0028] The present embodiment provides a method for preparing a positive electrode material for a high-entropy Prussian blue sodium-ion battery, comprising the following steps:

[0029] 1) 40mmol Na 4 Fe(CN) 6 ·10H 2 O, 14.7g of sodium citrate and 0.2g of polyvinylpyrrolidone were added to 20mL of deionized water to obtain a solution of sodium ferrocyanide, sodium citrate and surfactant;

[0030] 2) 4mmol of ferrous sulfate, 4mmol manganese sulfate, 4mmol cobalt sulfate, 4mmol nickel sulfate, 4mmol copper sulfate and 14.7g sodium citrate are dissolved in 20ml deionized water to form the solution of transition metal salt and sodium salt;

[0031] 3) adding the solution of transition metal salt and sodium salt obtained in step 2) into the solution of sodium ferrocyanide, sodium citrate and surfactant obtained in step 1) and mixing, stirring reaction, and stirring reaction temperature is 90 ℃. ℃, the stirring time is 2h, the stirring speed of the stirring reaction is 500rpm, a...

Embodiment 2

[0034] The present embodiment provides a method for preparing a positive electrode material for a high-entropy Prussian blue sodium-ion battery, comprising the following steps:

[0035] 1) 20mmol Na 4 Fe(CN) 6 ·10H 2 O, 7.5g sodium citrate and 0.2g 1,4-butynediol were added into 20mL deionized water to obtain a solution of sodium ferrocyanide, sodium citrate and surfactant;

[0036] 2) 4mmol of ferrous sulfate, 4mmol manganese sulfate, 4mmol cobalt sulfate, 4mmol nickel sulfate, 4mmol copper sulfate and 7.5g sodium citrate are dissolved in 20ml deionized water to form the solution of transition metal salt and sodium salt;

[0037]3) adding the solution of transition metal salt and sodium salt obtained in step 2) into the solution of sodium ferrocyanide, sodium citrate and surfactant obtained in step 1) and mixing, stirring reaction, and the stirring reaction temperature is 80 ℃. ℃, the stirring time is 1h, and the stirring speed of the stirring reaction is 400rpm. After the...

Embodiment 3

[0039] The present embodiment provides a method for preparing a positive electrode material for a high-entropy Prussian blue sodium-ion battery, comprising the following steps:

[0040] 1) 60mmol Na 4 Fe(CN) 6 ·10H 2 O, 22.05g sodium citrate and 0.2g polyvinyl alcohol were added into 20mL deionized water to obtain a solution of sodium ferrocyanide, sodium citrate and surfactant;

[0041] 2) 4mmol ferrous sulfate, 4mmol manganese sulfate, 4mmol cobalt sulfate, 4mmol nickel sulfate, 4mmol copper sulfate and 22.05g sodium citrate are dissolved in 20ml deionized water to form the solution of transition metal salt and sodium salt;

[0042] 3) the solution of transition metal salt and sodium salt obtained in step 2) is added to the solution of sodium ferrocyanide, sodium citrate and surfactant obtained in step 1) and mixed, and the stirring reaction is carried out at a temperature of 100 ℃. ℃, the stirring time is 3h, the stirring speed of the stirring reaction is 600rpm, after t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com