Rare-earth-based complex environment-friendly marine antifouling paint and preparation method thereof

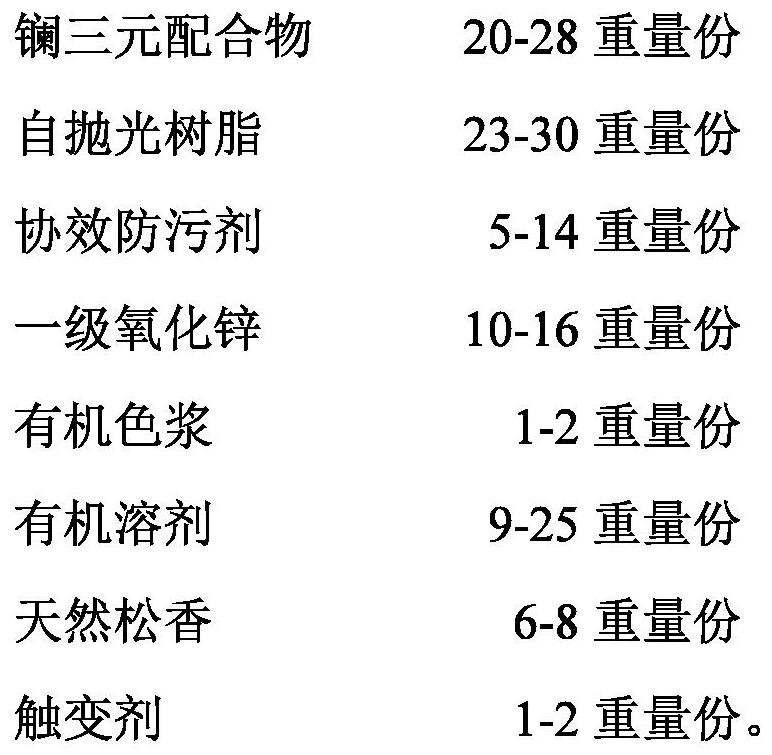

A marine antifouling and complex technology, applied in antifouling/underwater coatings, rosin coatings, coatings, etc., to achieve the effects of stable antibacterial performance, environmental protection and antifouling, and lasting antibacterial efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

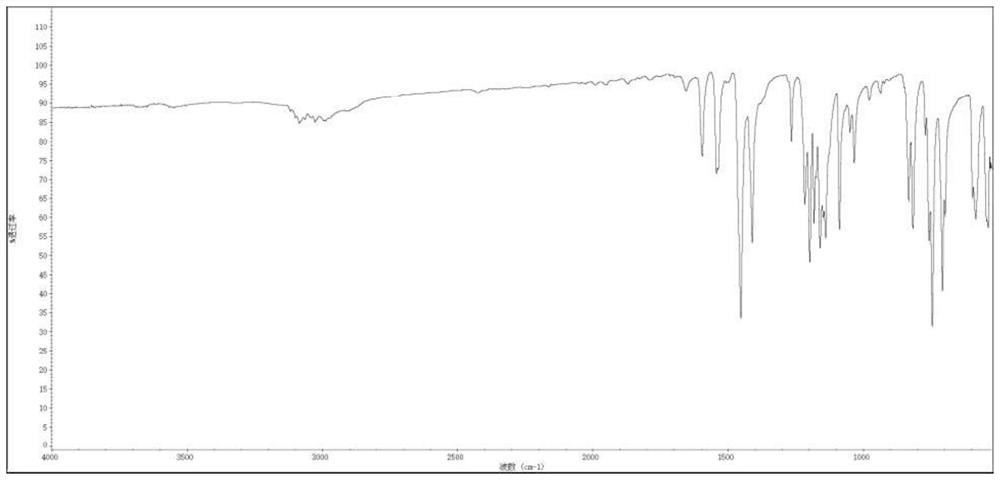

Image

Examples

preparation example Construction

[0038] The preparation method of the lanthanum ternary complex in the following examples is as follows:

[0039] (1) Preparation of lanthanum nitrate solution: Weigh 20 g of lanthanum nitrate, add it into 180 g of water, stir to dissolve, and set aside.

[0040] (2) Preparation of sodium pyrithione solution: weigh 50 g of sodium pyridinethione, add it to 150 g of absolute ethanol, stir to dissolve, and set aside for later use.

[0041] (3) Preparation of α-tryptophan solution: weigh 25 g of α-tryptophan, add 175 g of deionized water, stir to dissolve, and set aside.

[0042] (4) Under stirring conditions, the above-mentioned sodium pyrithione solution was added dropwise to the above-mentioned lanthanum nitrate solution, the dropwise addition time was about 10 minutes, and the stirring was continued for 20 minutes after the dropwise addition was completed.

[0043] (5) Under stirring conditions, the above-mentioned α-tryptophan solution was added dropwise to the material obtai...

Embodiment 1

[0053] (1) mix the zinc acrylate self-polishing resin, natural rosin, xylene and n-butanol and disperse for 50min at a speed of 800r / min to obtain a pre-dispersion;

[0054] (2) adding lanthanum ternary complex, zinc pyrithione, primary zinc oxide and yellow organic color paste to the above-mentioned pre-dispersion liquid, and dispersing at a rate of 1200r / min for 20min;

[0055] (3) The material obtained in step (2) is placed in a basket sand mill and sanded to a fineness of 85um, then a thixotropic agent organobentonite is added, dispersed at a speed of 1000r / min until the viscosity reaches 8000cp, and it is cooled. .

[0056] The raw material proportioning ratio of the present embodiment is shown in the following table 1:

[0057] Table 1

[0058] serial number Material name Mass percentage / % 1 Acrylic Zinc Self Polishing Resin 26 2 natural rosin 7 3 Xylene: n-butanol (mass ratio 1:1) 25 4 Lanthanum ternary complex 24 5 Zinc p...

Embodiment 2

[0063] (1) mix the zinc acrylate self-polishing resin, natural rosin, xylene, and 200# solvent oil and disperse at a speed of 1200r / min for 30min to obtain a pre-dispersion;

[0064] (2) adding lanthanum ternary complex, Sea-nine 211, zinc oxide, primary zinc oxide and gray organic color paste to the above-mentioned pre-dispersion liquid, and dispersing at a rate of 1000r / min for 30min;

[0065] (3) the material obtained in step (2) is placed in a basket sand mill and sanded to a fineness of 75um, then a thixotropic agent polyamide wax is added, dispersed at a speed of 1000r / min until the viscosity reaches 6500cp, and the cooling is to make.

[0066] The raw material proportioning ratio of the present embodiment is shown in the following table 3:

[0067] table 3

[0068] serial number Material name Mass percentage / % 1 Acrylic Zinc Self Polishing Resin 23 2 natural rosin 6 3 Xylene: 200# solvent oil (mass ratio 1:1) 17 4 Lanthanum ter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com