Optical fiber for high-transmission optical cable and preparation method thereof

A high-transmission, optical cable technology, applied in clad optical fiber, optical waveguide light guide, multi-layer core/clad optical fiber, etc., can solve problems affecting optical fiber, thermal expansion and contraction of optical fiber, optical cable structure distortion, etc., to achieve high transmission Performance, gain resistance to thermal expansion and contraction, and reduce the effect of cold deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

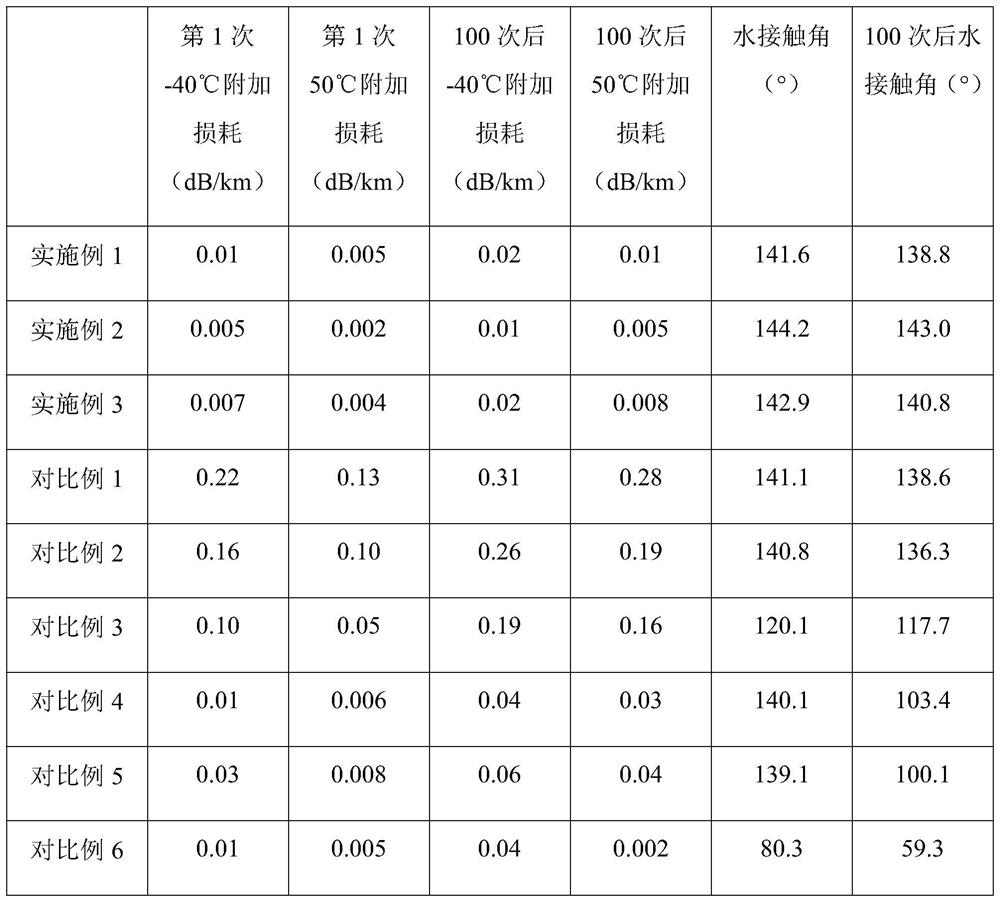

Examples

Embodiment 1

[0029] A preparation method of an optical fiber for a high transmission optical cable, the preparation method of the optical fiber for a high transmission optical cable mainly comprises the following preparation steps:

[0030](1) Place the glass substrate in deionized water with 8 times the mass of the glass substrate, add 3-aminopropyltrimethoxysilane with 0.3 times the mass of the glass substrate under 30 kHz ultrasound, react for 54 min, filter, and wash with deionized water for 3 times, and dried at 50 °C for 5 h to obtain the pretreated glass substrate;

[0031] (2) Fix the pretreated glass substrate with a clamp, and rotate at a speed of 2 rpm; mix graphene oxide, polystyrene and N,N-dimethylformamide in a mass ratio of 1:5:27 to obtain graphene oxide spinning liquid, 15cm away from the pretreated glass substrate, spinning at a spinning voltage of 10kV and 0.2mL / min to a thickness of 14μm, and then immersed in a coagulation bath with twice the mass of the pretreated gla...

Embodiment 2

[0037] A preparation method of an optical fiber for a high transmission optical cable, the preparation method of the optical fiber for a high transmission optical cable mainly comprises the following preparation steps:

[0038] (1) Place the glass substrate in deionized water with 10 times the mass of the glass substrate, add 3-aminopropyltrimethoxysilane with 0.4 times the mass of the glass substrate under 35 kHz ultrasound, react for 48 minutes, filter, and wash with deionized water for 4 times, and dried at 55 °C for 4 h to obtain the pretreated glass substrate;

[0039] (2) Fix the pretreated glass substrate with a clamp and rotate at a speed of 3.5 rpm; mix graphene oxide, polystyrene and N,N-dimethylformamide in a mass ratio of 1:5:27 to obtain graphene oxide spinning The silk liquid was 18cm away from the pretreated glass substrate. After spinning to a thickness of 19 μm at a spinning voltage of 12kV and 0.3mL / min, it was immersed in a coagulation bath with a mass of 3....

Embodiment 3

[0045] A preparation method of an optical fiber for a high transmission optical cable, the preparation method of the optical fiber for a high transmission optical cable mainly comprises the following preparation steps:

[0046] (1) Place the glass substrate in deionized water with 12 times the mass of the glass substrate, add 3-aminopropyltrimethoxysilane with 0.5 times the mass of the glass substrate under 40 kHz ultrasound, react for 42 min, filter, and wash with deionized water for 5 times, and dried at 60 °C for 3 h to obtain the pretreated glass substrate;

[0047] (2) Fix the pretreated glass substrate with a clamp and rotate at a speed of 5 rpm; mix graphene oxide, polystyrene and N,N-dimethylformamide in a mass ratio of 1:5:27 to obtain graphene oxide spinning liquid, 20 cm from the pretreated glass substrate, spin to a thickness of 24 μm at a spinning voltage of 15 kV and 0.4 mL / min, and then immerse it in a coagulation bath that is 5 times the mass of the pretreated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com