Method for synthesizing three-dimensional porous silicon powder from silane and application of three-dimensional porous silicon powder

A three-dimensional porous, silicon powder technology, used in structural parts, electrical components, battery electrodes, etc., to enhance rate performance, improve charge-discharge performance, and reduce absolute expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

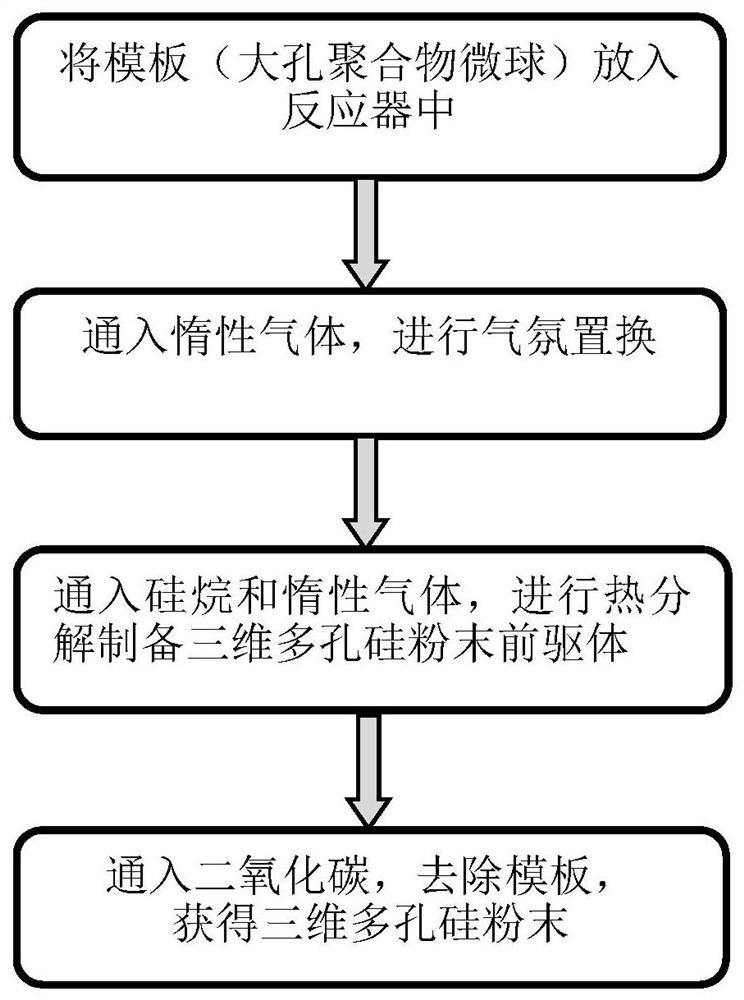

[0034] see figure 1 The process of 0.01t of macroporous polystyrene microspheres with an average particle size D50 of 3 μm and a pore size of 0.1 μm was put into the fluidized bed reactor, and then argon was introduced into the fluidized bed reactor at the same time, and the flow rate was At 10 L / h, atmosphere replacement was performed. Then, monosilane and helium were simultaneously introduced into the fluidized bed reactor. The flow rates of monosilane and helium were both 10 L / h, and the reactor was heated to 400°C. After 3 hours of heat preservation, the inflow of monosilane and helium was stopped. Then, carbon dioxide was continuously introduced into the fluidized bed reactor with a flow rate of 10L / h, heated to 900°C, maintained for 1h, then stopped heating, and cooled to room temperature with the reactor to obtain three-dimensional through-holes with a pore diameter of 10-40nm. / Porous structure of three-dimensional porous silicon powder.

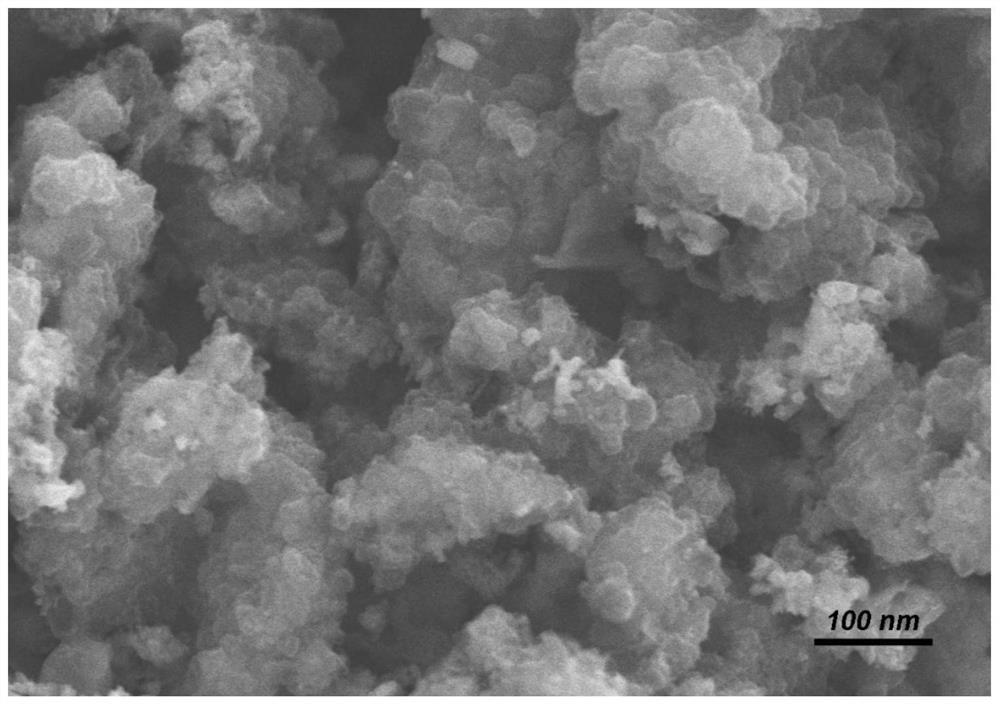

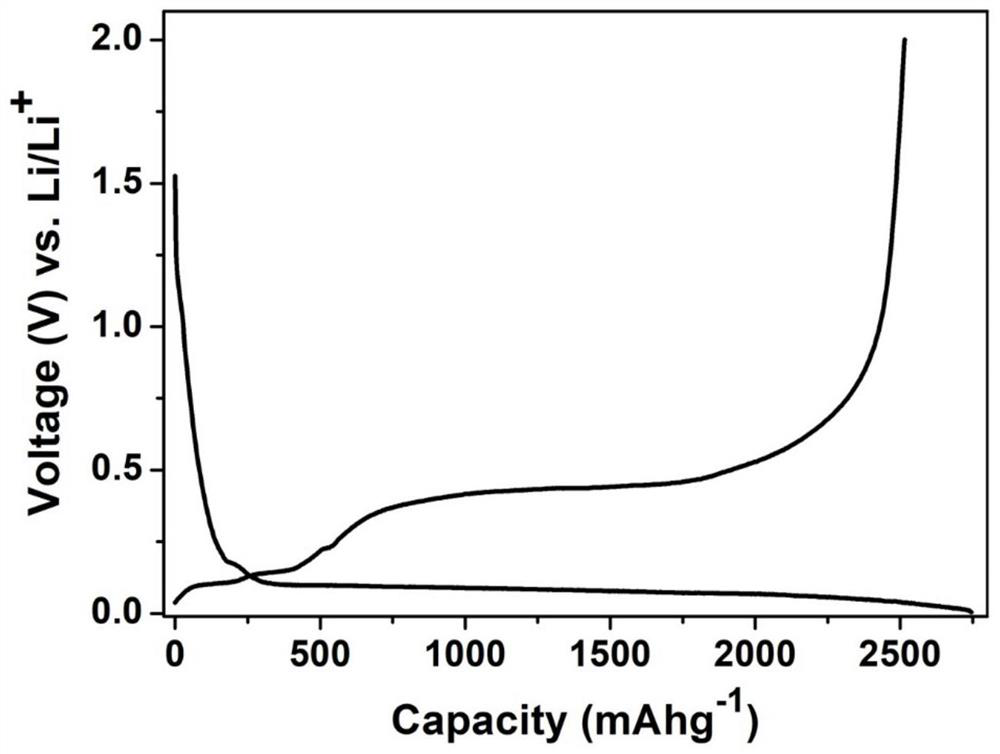

[0035]The obtained three-d...

Embodiment 2

[0037] see figure 1 The process of 0.1t of macroporous polystyrene microspheres with an average particle size D50 of 5μm and a pore size of 0.3μm and 0.1t of macroporous polyvinyl chloride microspheres with an average particle size of 6μm and a pore size of 0.2μm are mixed uniformly. Put it into a fluidized bed reactor, and then pass argon and helium into the fluidized bed reactor at the same time, with a flow rate of 200 L / h, to perform atmosphere replacement. Then, the mixed gas of disilane and monochlorosilane, argon and helium were simultaneously introduced into the fluidized bed reactor, wherein the gas volume ratio of disilane and monochlorosilane was 5:1, and the flow rate was 450 L / h. The flow rates of argon and helium were both 200L / h, heated to 500°C, and kept for 10h. Then stop feeding the mixed gas of disilane, monochlorosilane, argon and helium. Then, carbon dioxide was continuously introduced into the fluidized bed reactor with a flow rate of 450 L / h, heated to...

Embodiment 3

[0041] see figure 1 The process of 0.2t of macroporous polypropylene microspheres with an average particle size D50 of 7μm and a pore size of 0.3μm and 0.1t of macroporous polyvinyl chloride microspheres with an average particle size of 7μm and a pore size of 0.2μm are mixed evenly and placed into the CVD reactor, and then argon gas was introduced into the CVD reactor at a flow rate of 800 L / h, and the atmosphere was replaced. Then, the mixed gas of trisilane and dichlorosilane and argon were simultaneously introduced into the CVD reactor. The gas ratio of trisilane and dichlorosilane was 6:1, the flow rate was 1100L / h, and the flow rate of argon was 1200L / h. , heated to 700 ℃, after 8 hours of heat preservation, the mixed gas of trisilane, dichlorosilane and argon were stopped. Then, carbon dioxide was continuously introduced into the fluidized bed reactor with a flow rate of 1000 L / h, heated to 1000 °C, kept at a temperature of 2 h, then stopped heating, and cooled to room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com