Method for relieving membrane protein pollution by FeOCl modified ceramic membrane in-situ coupling peracetic acid catalytic filtration system

A peracetic acid and catalytic filtration technology, which is applied in the field of membrane protein pollution mitigation, can solve the problems of ceramic membrane protein pollution that cannot be effectively solved, low filtration efficiency, high operation and maintenance costs, etc., to improve anti-pollution performance, high oxidation efficiency, Effect of Membrane Fouling Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

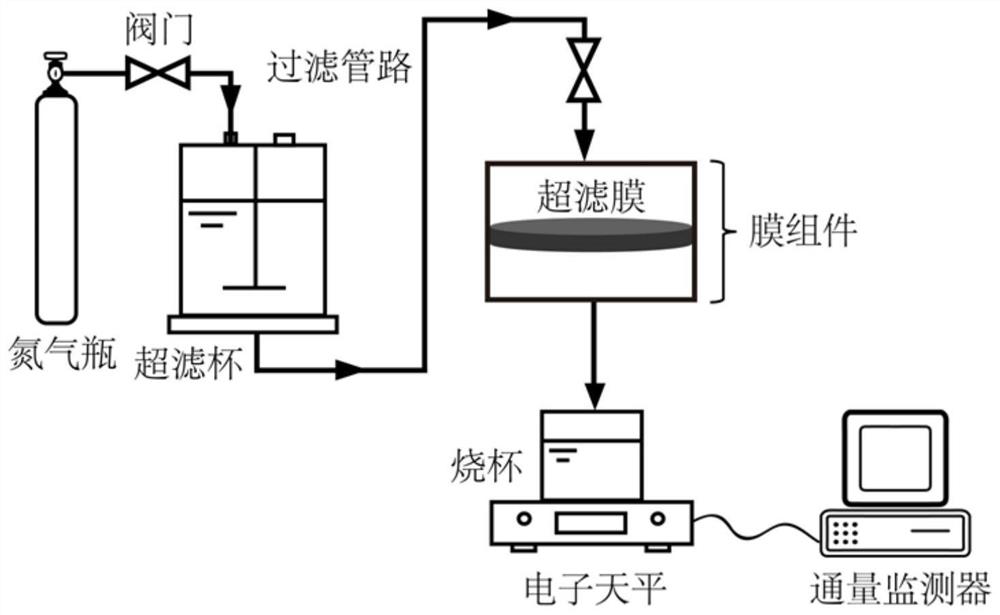

[0030] A FeOCl modified ceramic membrane in-situ coupling peracetic acid catalytic filtration system of the present embodiment is constructed as follows:

Embodiment 2

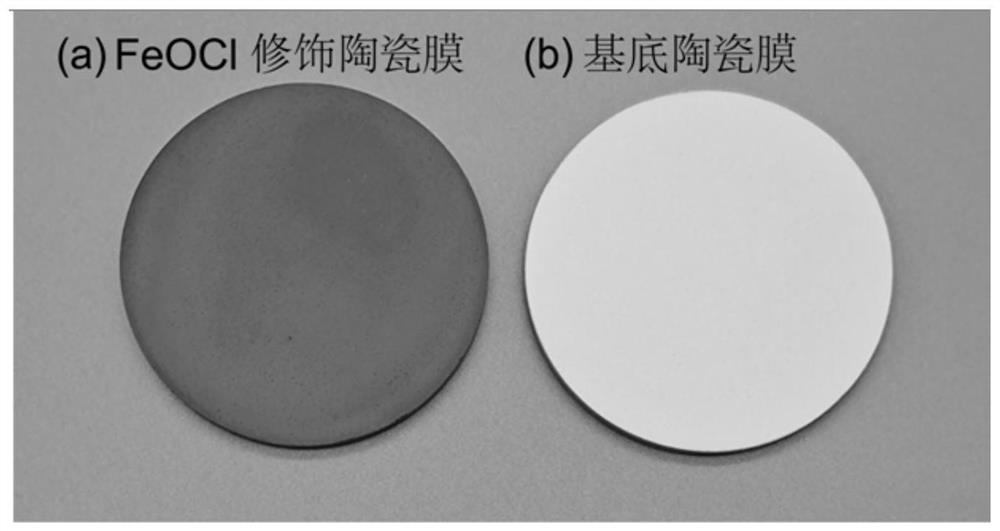

[0034] The preparation method of the FeOCl modified ceramic membrane in the in-situ coupling of the FeOCl modified ceramic membrane described in Example 1 in the peracetic acid catalytic filtration system is as follows:

[0035] FeOCl modified ceramic membranes were prepared by solution infiltration and heating calcination. Among them, a flat circular ceramic membrane is used as the catalytic membrane substrate, and its main components are titanium dioxide and zirconium dioxide, the molecular weight cut off is 300kDa, the diameter is 47mm, and the thickness is 2.5mm. The purity of ferric chloride hexahydrate required for preparation is ≥99%.

[0036] A certain amount of ferric chloride hexahydrate powder was weighed with an electronic balance and dissolved in absolute ethanol, and magnetically stirred at 300 rpm to obtain a homogeneous solution. The ceramic membrane substrate was placed in a dry glass petri dish and immersed in the above solution, followed by sonication at 40...

Embodiment 3

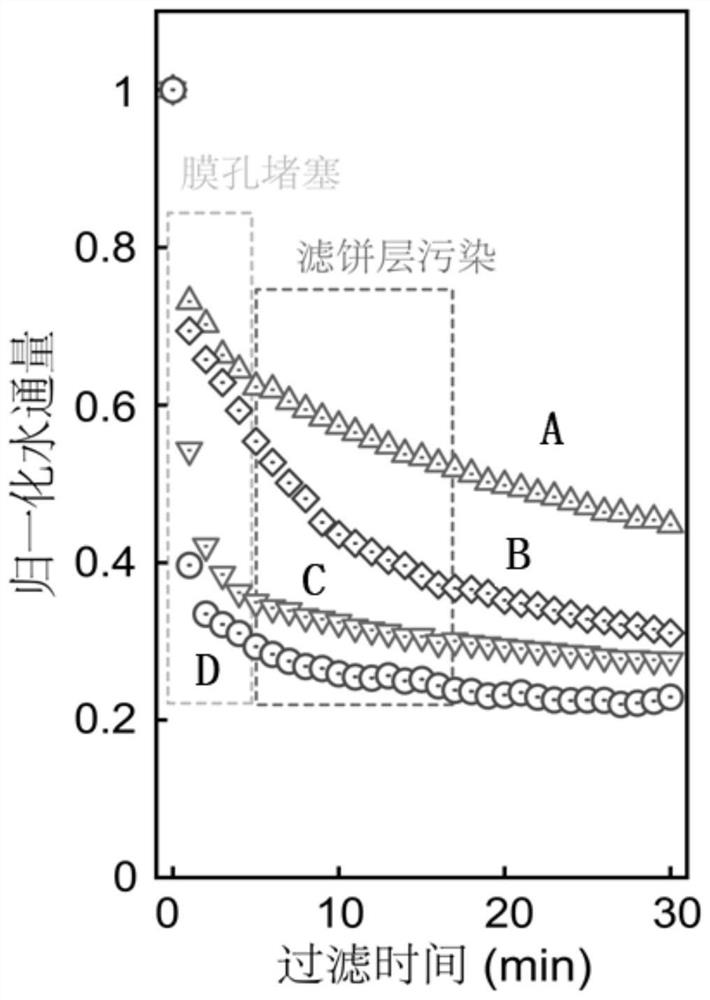

[0039] The FeOCl modified ceramic membrane described in Example 1 in-situ coupled with the peracetic acid catalytic filtration system has the following effects on relieving membrane protein pollution:

[0040] The model contaminant used was bovine serum albumin and the oxidant used was peracetic acid. Among them, operation mode I is the catalytic filtration mode using FeOCl modified ceramic membrane and adding peracetic acid oxidant during filtration; operation mode II is the membrane filtration mode using base ceramic membrane and adding peracetic acid oxidant during filtration; operation mode III is using FeOCl modified ceramic membrane, membrane filtration mode without adding oxidant during filtration; operation mode IV is the membrane filtration mode using base ceramic membrane, without adding oxidant during filtration.

[0041] Scanning electron microscopy (SEM) was used to characterize the microscopic morphology of bovine serum albumin on the surface and cross-section of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com