Positive electrode material precursor, preparation method thereof and positive electrode material

A cathode material and precursor technology, applied in the field of sodium-ion batteries, can solve the problems that the precipitation rate of metal elements cannot be maintained stably, the synergistic effect of elements cannot be fully exerted, and the specific capacity of the product is affected, so as to improve cycle stability and regular morphology , Improve the effect of tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

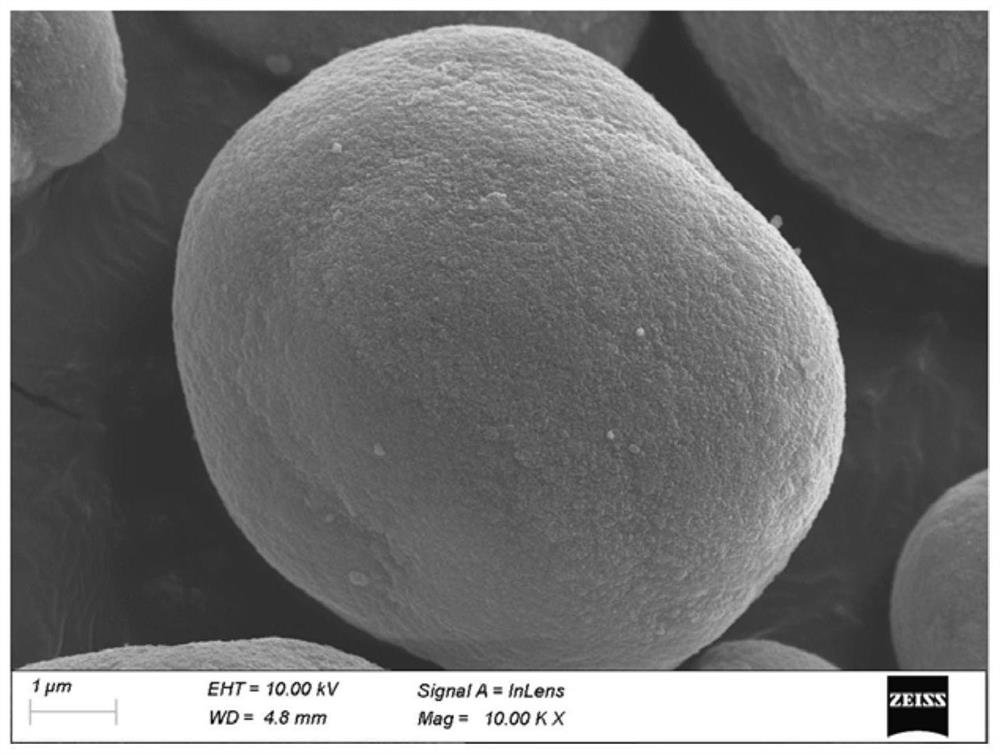

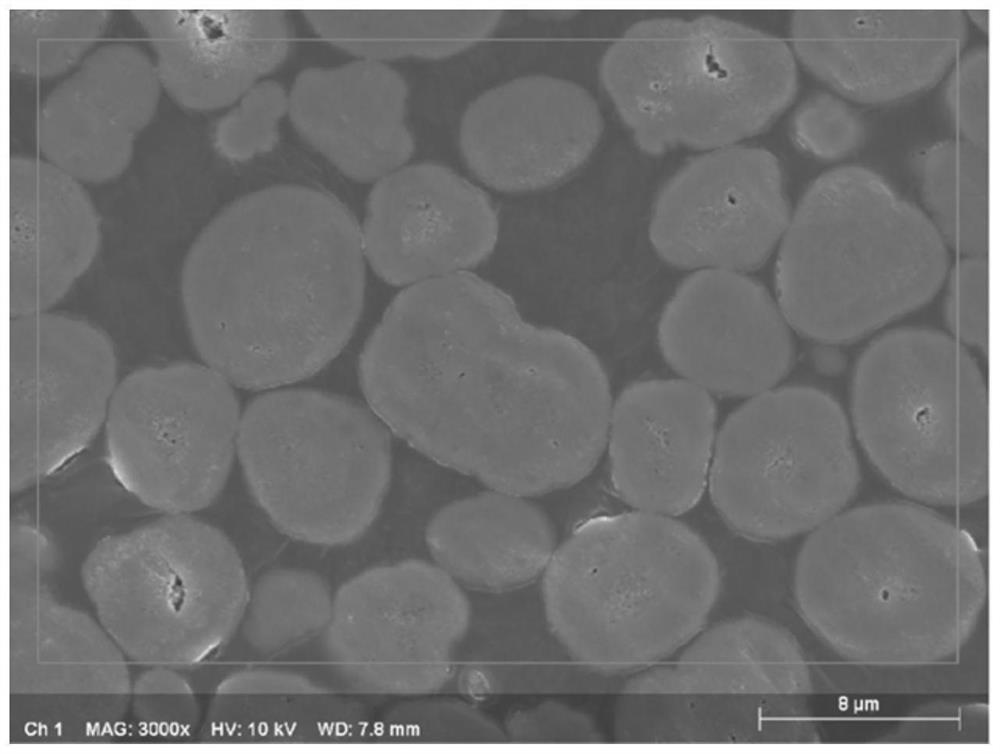

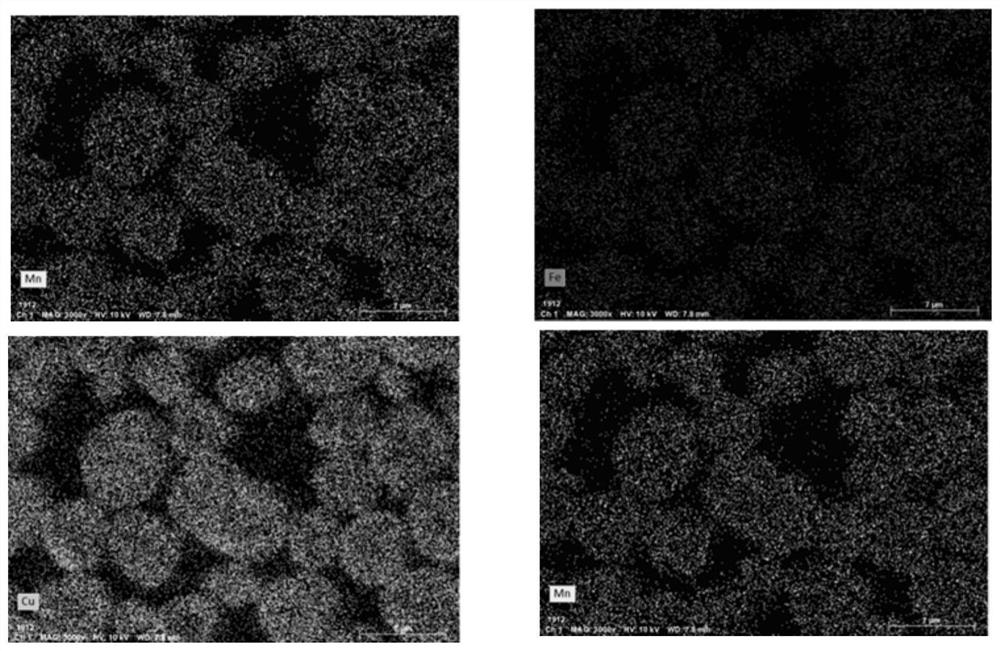

[0051] This embodiment provides a preparation method and precursor of a positive electrode material precursor:

[0052] (1) Weigh manganese sulfate and nickel sulfate, mix, and dissolve in water to obtain manganese sulfate (concentration of 0.90mol / L) and nickel sulfate (concentration of 0.60mol / L) mixed metal liquid. Weigh ferric sulfate and copper sulfate, mix, and dissolve in water to obtain a mixed metal solution of ferric sulfate (concentration: 0.45 mol / L) and copper sulfate (concentration: 0.60 mol / L). Weigh sodium hydroxide and add deionized water to prepare a 4 mol / L sodium hydroxide solution.

[0053] (2) In the above-mentioned mixed metal solution of iron sulfate and copper sulfate, sodium citrate was added to make the concentration in the solution 20g / L, and the complexation reaction was carried out. The reaction temperature was 25°C and the time was 1h.

[0054] (3) add 4L of water in the reaction kettle, add 5mL of hydrazine hydrate, add 30g of sodium citrate, t...

Embodiment 2

[0056] This embodiment provides a preparation method and precursor of a positive electrode material precursor:

[0057] (1) Weigh manganese sulfate and nickel sulfate, mix, and dissolve in water to obtain manganese sulfate (concentration of 0.90mol / L) and nickel sulfate (concentration of 0.60mol / L) mixed metal liquid. Weigh ferrous sulfate and copper sulfate, mix, and dissolve in water to obtain a mixed metal liquid of ferrous sulfate (concentration of 0.90 mol / L) and copper sulfate (concentration of 0.60 mol / L). Weigh sodium hydroxide and add deionized water to prepare a 4 mol / L sodium hydroxide solution.

[0058] (2) In the above-mentioned mixed metal solution of iron sulfate and copper sulfate, sodium citrate was added to make the concentration in the solution 20g / L, and the complexation reaction was carried out. The reaction temperature was 25°C and the time was 1h.

[0059] (3) add 4L of water in the reaction kettle, add 5mL of hydrazine hydrate, add 30g of sodium citrat...

Embodiment 3

[0061] This embodiment provides a preparation method and precursor of a positive electrode material precursor:

[0062] (1) Weighing manganese sulfate and nickel sulfate, mixing, and dissolving in water to obtain a mixed metal liquid of manganese sulfate (concentration of 0.60 mol / L) and nickel sulfate (concentration of 0.90 mol / L). Weigh ferric sulfate and copper sulfate, mix, and dissolve in water to obtain a mixed metal solution of ferric sulfate (concentration: 0.45 mol / L) and copper sulfate (concentration: 0.60 mol / L). Weigh sodium hydroxide and add deionized water to prepare a 4 mol / L sodium hydroxide solution.

[0063] (2) In the mixed metal solution of ferric sulfate and copper sulfate prepared in step (1), sodium citrate was added to make the concentration in the solution 20g / L, and a complexation reaction was carried out, the reaction temperature was 25°C, and the time was 1h .

[0064] (3) add 4L of water in the reaction kettle, add 5mL of hydrazine hydrate, add 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com