Environment-friendly iron runner castable with excellent slag corrosion resistance

A technology of slag erosion resistance and iron channel castables, which is applied in the direction of climate sustainability, process efficiency improvement, sustainable waste treatment, etc., can solve toxic and harmful choking yellow smog, uneven distribution of castable components, increased The amount of water added to the castable and other issues can be achieved to achieve excellent corrosion resistance to slag and iron, avoid toxic and harmful smoke, and enhance the effect of oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

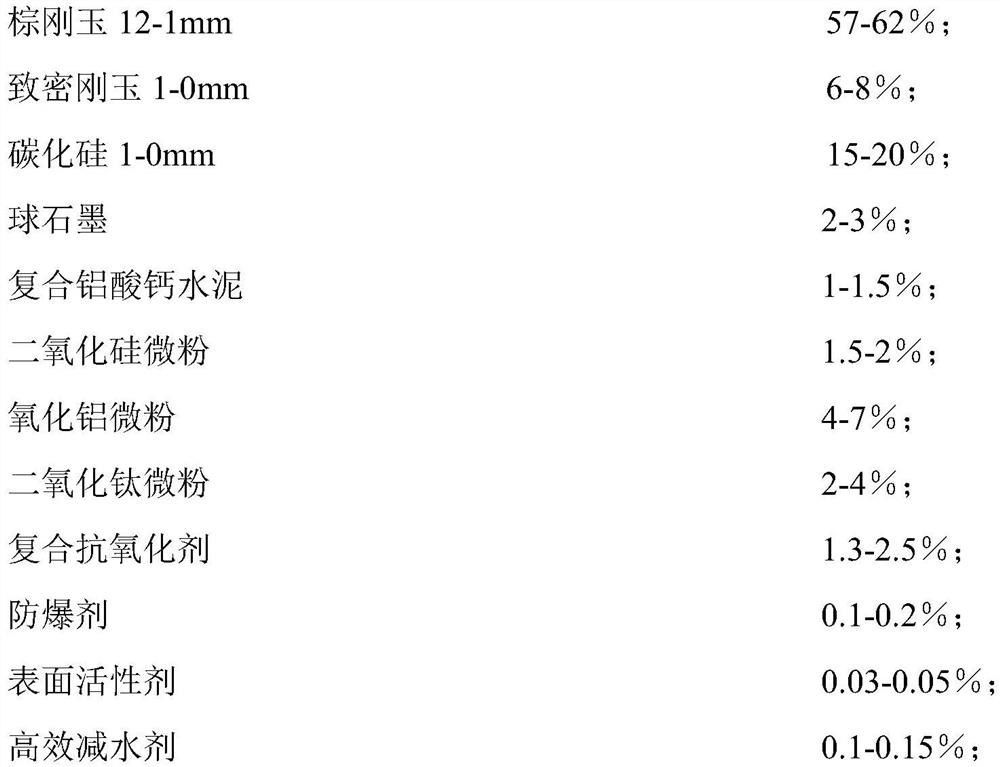

[0054] The iron trench castable is composed of the following components and percentages by weight:

[0055]

[0056] See Table 1 for the performance index test results of the iron trench castable provided in this example.

Embodiment 2

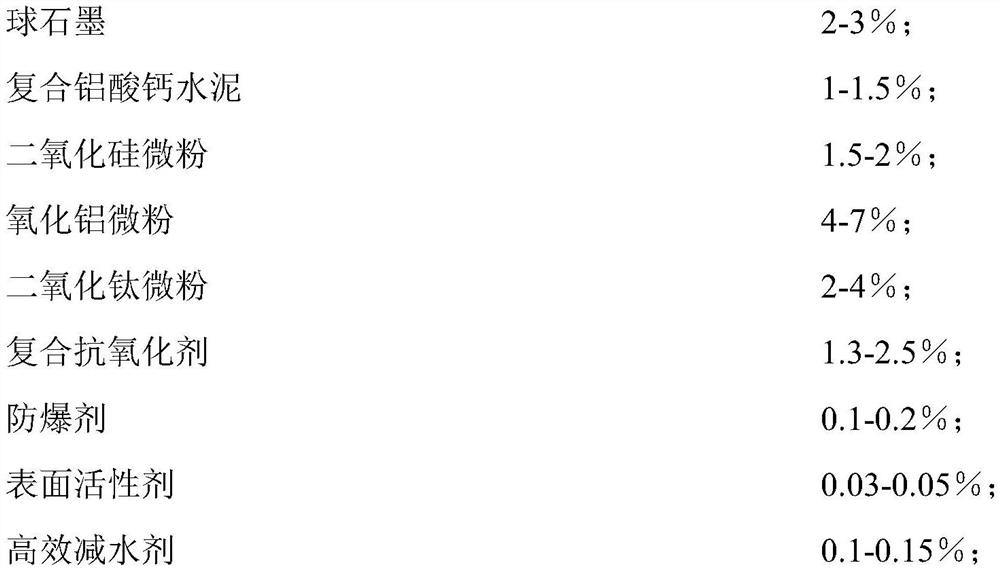

[0058] The iron trench castable is composed of the following components and percentages by weight:

[0059]

[0060]

[0061] See Table 1 for the performance index test results of the iron trench castable provided in this example.

Embodiment 3

[0063] The iron trench castable is composed of the following components and percentages by weight:

[0064]

[0065] See Table 1 for the performance index test results of the iron trench castable provided in this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com