RFID-based two-way communication intelligent testing and adjusting method and system for water injection/producing well

A two-way communication, water injection well technology, applied in wellbore/well components, measurement, production of fluids, etc., can solve the problems of large influence of wellbore diameter, inability to achieve two-way communication between surface and underground, and achieve low construction risk and ensure information reading. Take the effect of reliability and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

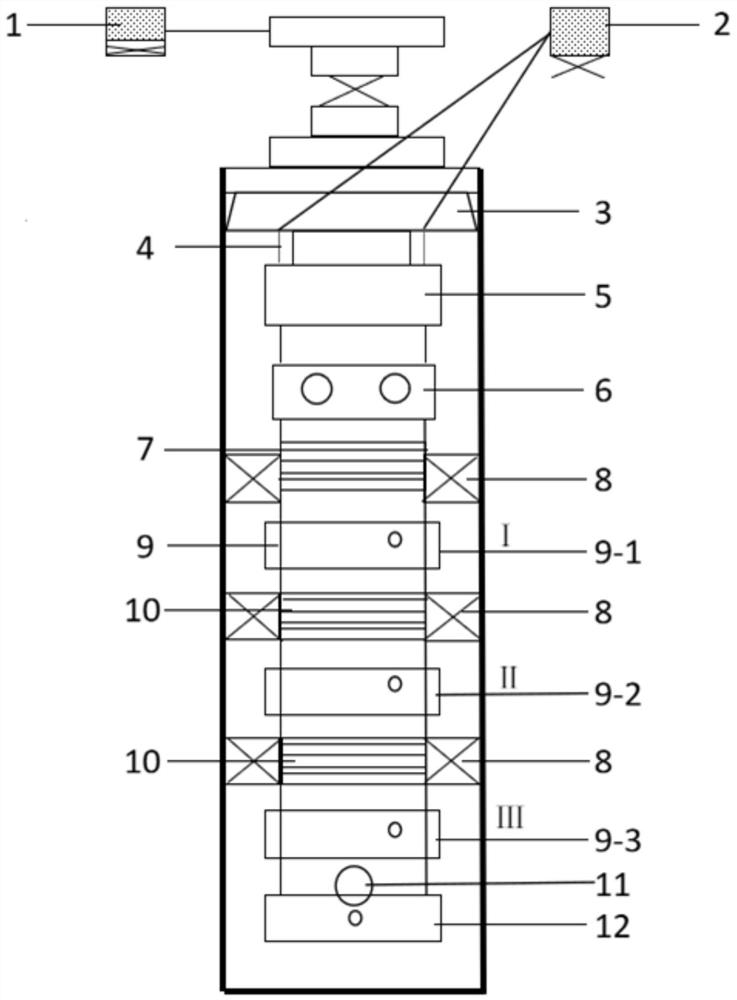

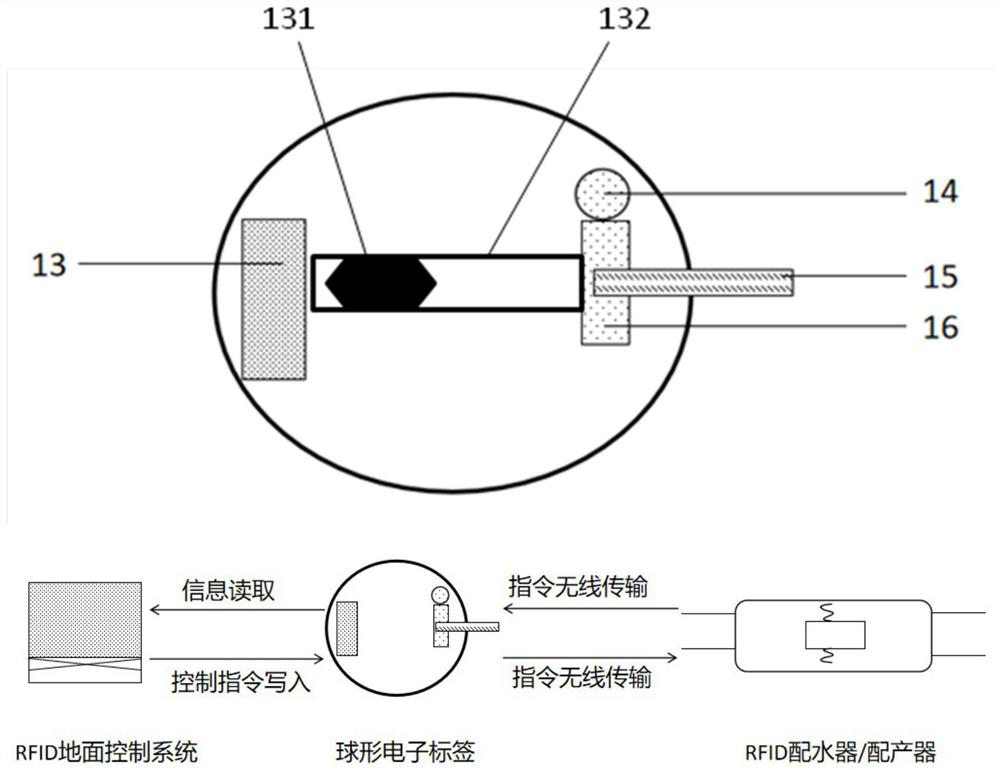

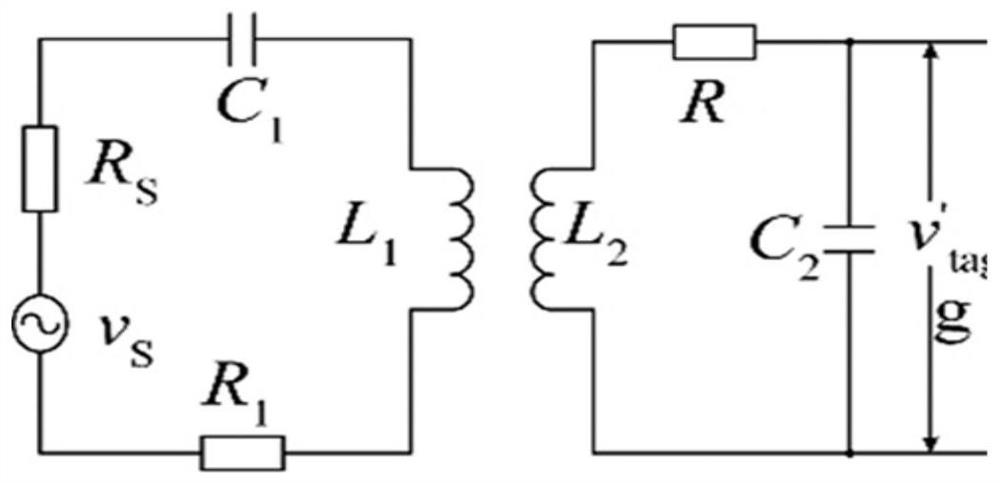

[0049] like figure 1 As shown, the ground part of the water injection well includes an RFID ground control system 1, a hydraulic station 2, and an oil pipe string 3, a hydraulic control pipeline 4, a backwashing well lifting device 5, a sliding sleeve 6, and a top seal positioning seal are arranged in sequence from top to bottom. 7. Isolation packer 8, RFID water distributor 9, insert seal 10, water injection level I, water injection level II, and water injection level III respectively correspond to an RFID water distributor, the RFID water distributor 9 has built-in flow, pressure, temperature Other sensors, motors, wireless radio frequency modules and core processors are used to receive and process the instruction information carried by the spherical electronic tag 11, and then realize the adjustment of the valve opening through the motor, and also have the function of transmitting radio frequency signals. The control system 1 includes a PC equipped with ground controller op...

Embodiment 2

[0058] like Figure 4 As shown, the oil production well includes an RFID surface control system 1, a pump operating condition surface controller 17, a steel armored cable 18, and an isolation packer 8, a Y joint 19, a seat plug 20, and an oil drain set from top to bottom. 21. Electric pump 22, pump condition 23, top seal positioning seal 7, isolation packer 8, RFID dispenser 24, insert seal 10, round plug 25, the pump condition 23 has a built-in radio frequency module and core processing The electric pump is connected to the ground controller 17 of the pump working condition through the steel armored cable 18, and a seating spherical surface is arranged below the seating plug 20, so that after oil recovery is resumed, the electric pump sucks the spherical electronic tag 11 to the seating plug 20. In the spherical surface, to avoid blocking the overflow channel of the oil drain 21, the RFID dispenser has built-in sensors such as flow, pressure and temperature, as well as a moto...

Embodiment 3

[0067] On the basis of Embodiment 1 and Embodiment 2, this embodiment further includes:

[0068] According to the parameter information such as flow rate, pressure and temperature fed back by the RFID water distributor 9, look up the numerical correspondence table in the database to determine the flow interference coefficient K of the spherical electronic tag and the electromagnetic interference coefficient P of the spherical electronic tag;

[0069] Wherein, the flow interference coefficient K is defined as the reciprocal of the ratio of the flow velocity of the spherical electronic tag in the corresponding downhole environment to the flow velocity in clean water under the same flow, pressure and temperature environment. The greater the interference of the flow of the spherical electronic label, the numerical correspondence table between the flow interference system K and the downhole environment is established by the finite element analysis method, and the numerical corresponde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com