Method for processing and using SiC substrate without positioning edge

A processing method, a technology without positioning, applied in chemical instruments and methods, polycrystalline material growth, crystal growth and other directions, which can solve the problems of not substantially improving the positioning edge stress, reducing the utilization area of the substrate, and high probability of crystal cracking. , to achieve the effect of improving production quality and yield, reducing production costs, and reducing crystal processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0054] Embodiments of the invention and features of the embodiments may be combined with each other without conflict.

[0055] Terminology Description:

[0056] Seed face: refers to the side of the crystal that contains the seed;

[0057] Primary surface: refers to the growth surface of the crystal. Generally, the surface is uneven, and there are growth stripes, facets, etc.;

[0058] Cutting head piece: refers to the first cutting piece near or / and containing the seed crystal, generally there is a carbon ring around it;

[0059] Cutting tail piece: refers to the first cutting piece close to or / and including the natural surface, generally the diameter is smaller than the target diameter, and there is a "slope";

[0060] Off-axis SiC crystal: It means that the surface normal of the crystal does not coincide with the c-axis, and deviates from the c-axis by a certain small angle along the [11-20] or [1-100] direction.

[0061] According to the prior art, the presence of V-shap...

Embodiment 1

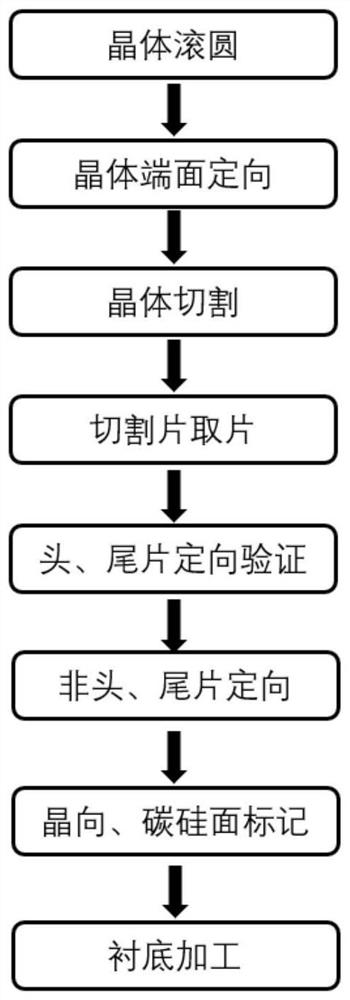

[0063] attached figure 1 As shown, this embodiment discloses a method for processing and using a SiC substrate without positioning edges, including:

[0064] 1) Spheronization: The grown SiC crystal is subjected to cylindrical grinding to make the outer diameter of the SiC crystal to the target size;

[0065] 2) Orientation: use the orientation instrument to orient the outer circle of the crystal, accurately determine the [1-100] and [11-20] directions of the crystal, and mark the outer circle of the crystal;

[0066] 3) Crystal cutting: The crystal is bonded to the cutting base according to a specific direction, and the cutting process parameters are set by a multi-wire cutting machine, and the SiC crystal is processed into a cutting piece;

[0067] 4) Cut and take slices: use a heating platform to bake the slices from the cutting base, take out and mark the carbon silicon surface of the head or tail of the slice, and clean the slice to remove the residual cutting fluid on t...

Embodiment 2

[0090] The purpose of this embodiment is to provide a 4H-SiC substrate processing and using method without positioning edges, which specifically includes the following operation steps:

[0091] 1) Spheronization: The silicon surface obtained by the growth is subjected to cylindrical grinding along the [11-20] direction off-axis to the 4°SiC crystal, so that the outer diameter of the 4H-SiC crystal is processed to 150mm;

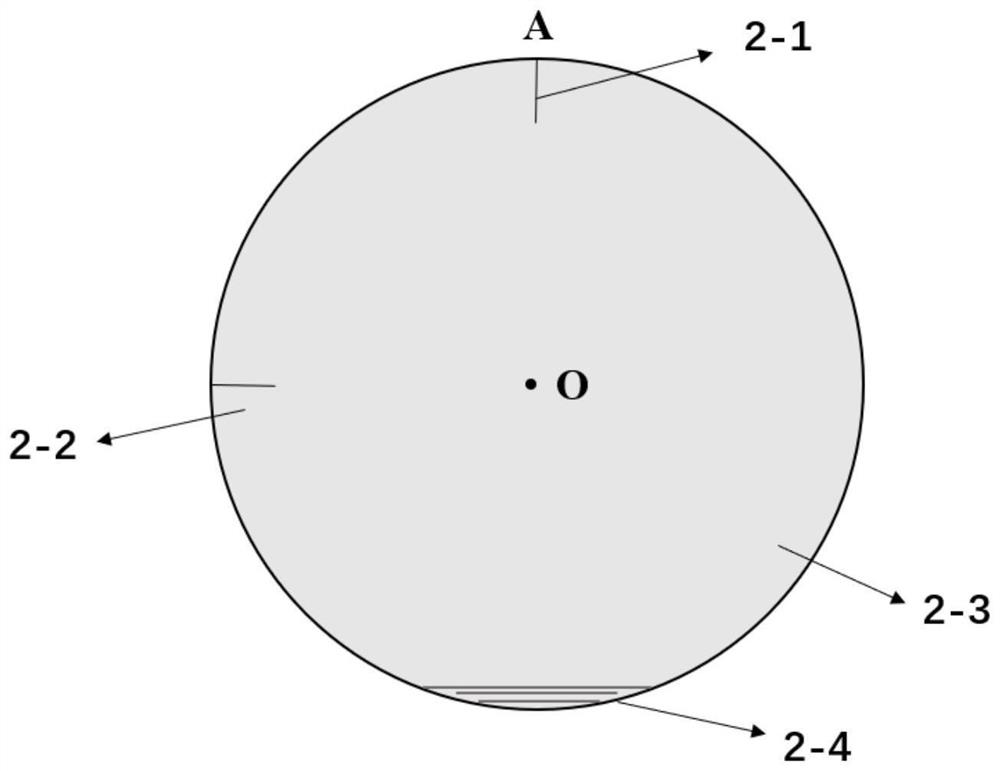

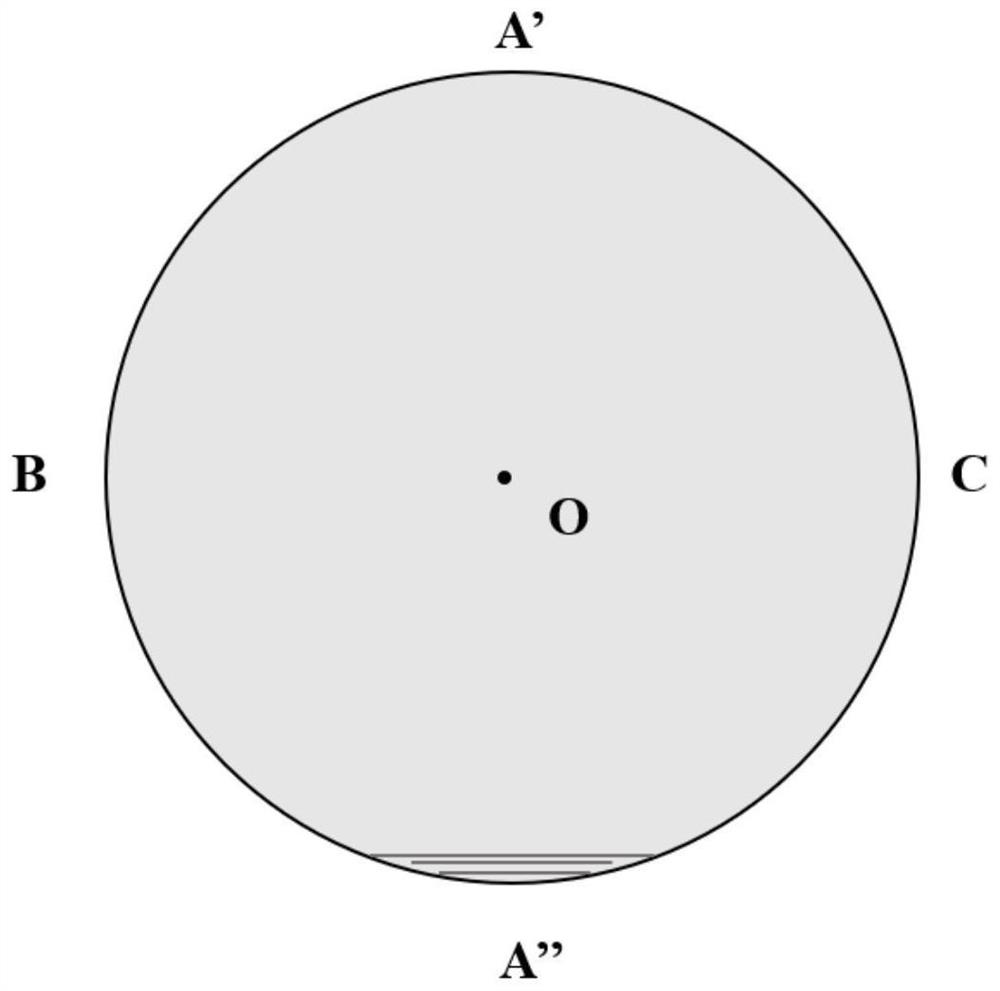

[0092] 2) Orientation: Use the orientation instrument to orient the outer circle of the crystal, accurately determine the and [11-20] directions of the crystal, and mark the crystal orientation with a marker on the outer circle of the crystal. The crystal plane and the original plane are marked with silicon plane and carbon plane respectively;

[0093] 3) Crystal cutting: The [11-20] direction of the crystal mark is vertically upward, and then the crystal is bonded to the graphite cutting base, and the cutting process parameters are set by a multi-wire cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com