Laminated organic light-emitting device

An electroluminescent device and electroluminescent technology, applied in the fields of electro-solid devices, organic chemistry, luminescent materials, etc., to achieve the effect of improving device performance, improving device performance, and increasing device stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

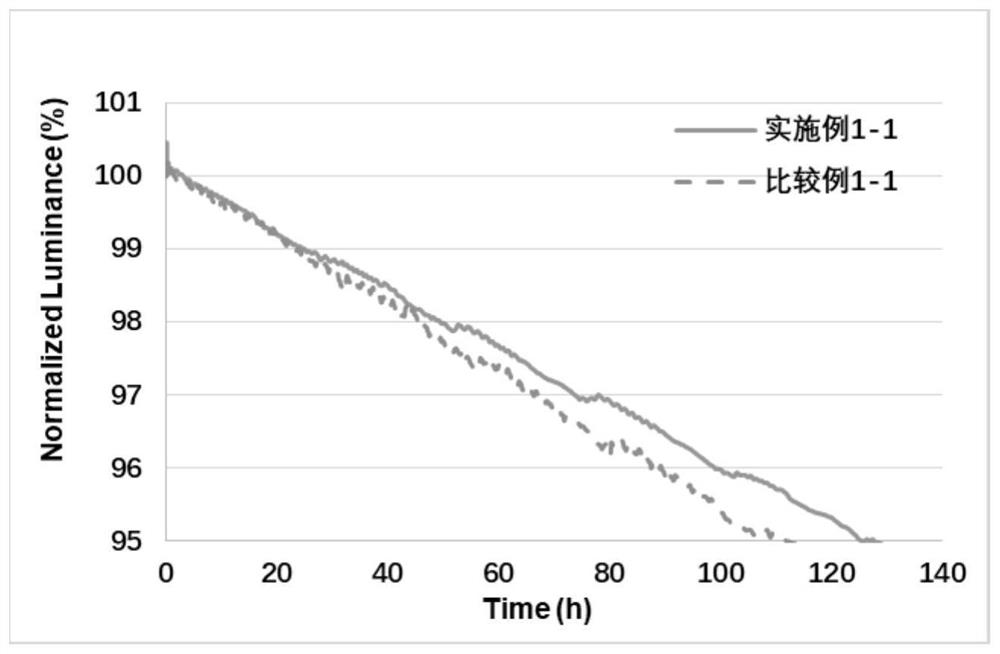

Embodiment 1-1

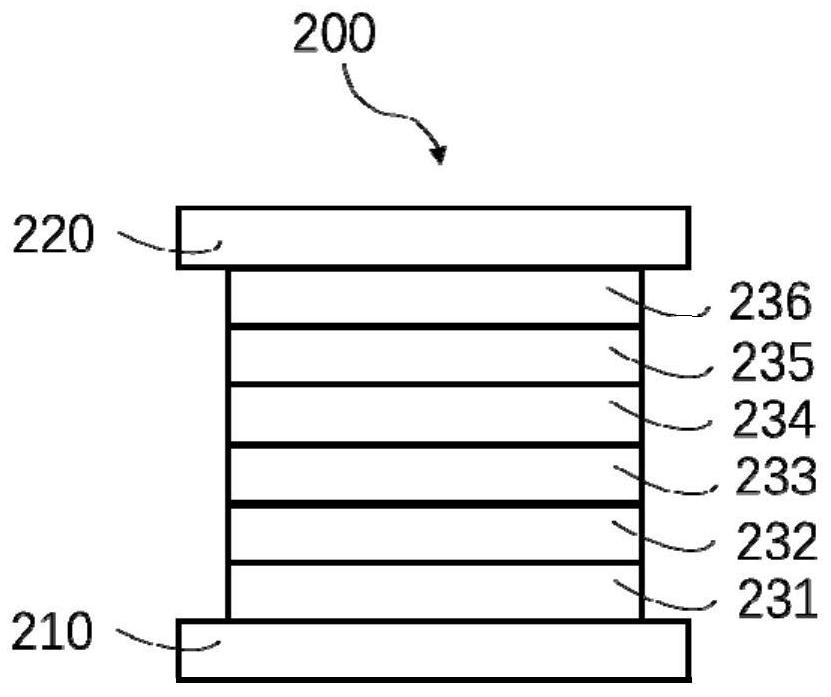

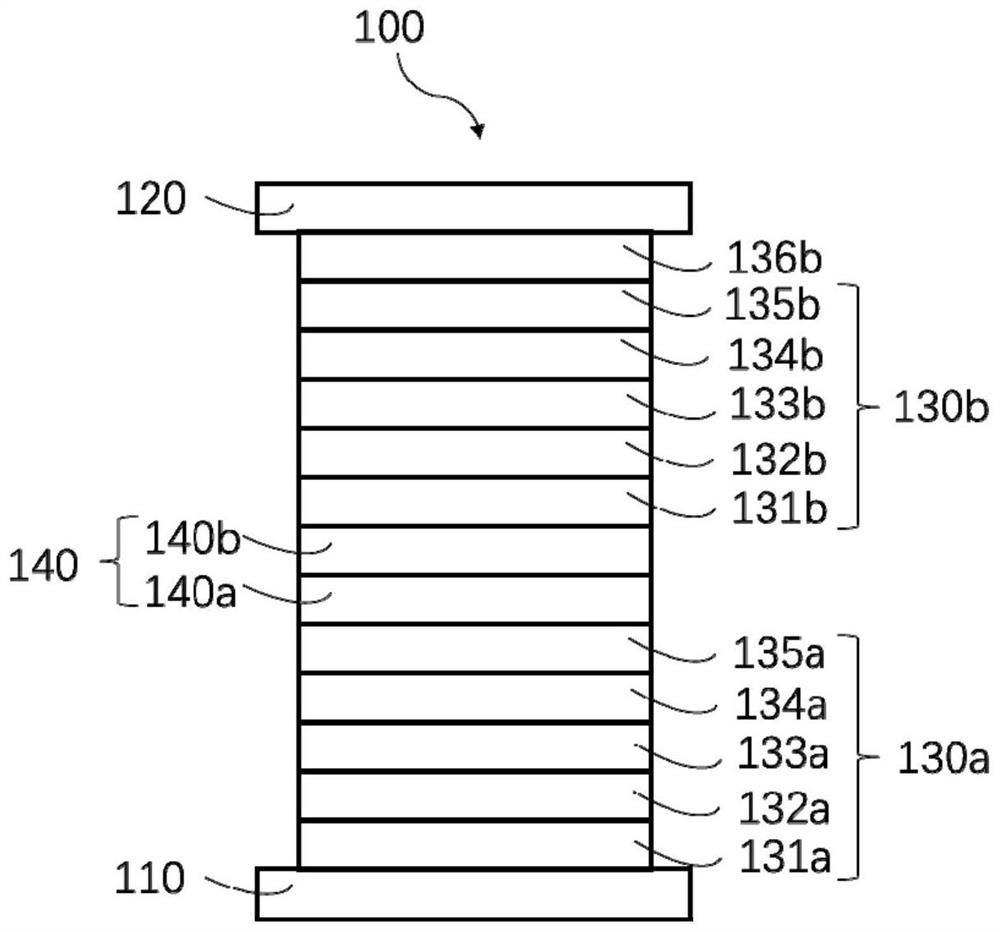

[0201] Example 1-1: Preparation of two-layer red light stacked organic electroluminescence device 100, such as figure 1 shown.

[0202] First, using a 0.7 mm thick glass substrate with a pre-patterned 120 nm thick indium tin oxide (ITO) anode 110, the ITO surface was subjected to oxygen plasma and UV ozone after washing the substrate with deionized water and detergent. deal with. Subsequently, the substrates were dried in a glove box to remove moisture and loaded onto a rack into a vacuum chamber. The organic layer specified below, at a vacuum of approximately 10 -6 In the case of Torr, the evaporation was sequentially performed on the ITO anode layer by vacuum thermal evaporation at a rate of 0.1-10 Å / sec. First, the first light-emitting unit 130a is vapor-deposited, including: simultaneously vapor-depositing compound H-124 and compound 1-70 as the hole injection layer 131a (HIL, weight ratio 97:3, ), the vapor-deposited compound H-124 was used as the hole transport laye...

Embodiment 2-1

[0217] Example 2-1: Preparation of another red light stacked organic electroluminescent device. The preparation method is the same as that of Example 1-1, except: 1) In the first light-emitting unit, the following hole injection layer is used instead of the hole injection layer of the first light-emitting unit in Example 1-1, and the following holes are used A transport layer to replace the hole transport layer of the first light-emitting unit in Example 1-1: Compound H-176 and Compound 1-70 were simultaneously evaporated as a hole injection layer (HIL, weight ratio 97:3, ), the evaporation compound H-176 was used as a hole transport layer (HTL, ); 2) In the second light-emitting unit, the following hole injection layer was used to replace the hole injection layer of the second light-emitting unit in Example 1-1, and the following hole transport layer was used to replace the hole injection layer of Example 1-1. Hole transport layer of two light-emitting units: Compound H-17...

Embodiment 3-1

[0228] Example 3-1: Preparation of another red light stacked organic electroluminescent device. The preparation method is the same as that of Example 1-1, except: 1) In the first light-emitting unit, the following hole injection layer is used instead of the hole injection layer of the first light-emitting unit in Example 1-1, and the following holes are used A transport layer to replace the hole transport layer of the first light-emitting unit in Example 1-1: Compound H-176 and Compound 1-70 were simultaneously evaporated as a hole injection layer (HIL, weight ratio 97:3, ), the evaporation compound H-176 was used as a hole transport layer (HTL, ); 2) In the second light-emitting unit, the following hole injection layer was used to replace the hole injection layer of the second light-emitting unit in Example 1-1, and the following hole transport layer was used to replace the hole injection layer of Example 1-1. Hole transport layer of two light-emitting units: Compound H-17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com