Surface-modified zinc oxide film, organic solar cell and preparation method thereof

A zinc oxide thin film and solar cell technology, applied in zinc oxide/zinc hydroxide, circuits, photovoltaic power generation, etc., can solve the problems of poor battery stability, complex methods and processes, and low battery performance, and achieve low cost, simple process, The effect of reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] One aspect of the embodiments of the present invention provides a method for preparing a surface-modified zinc oxide film, which includes:

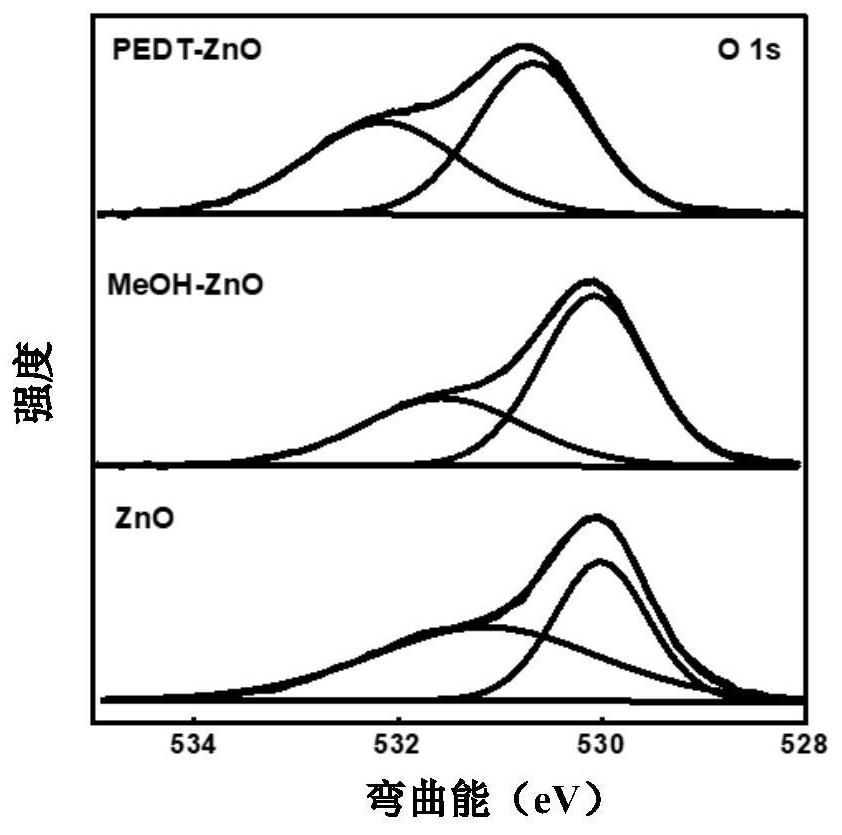

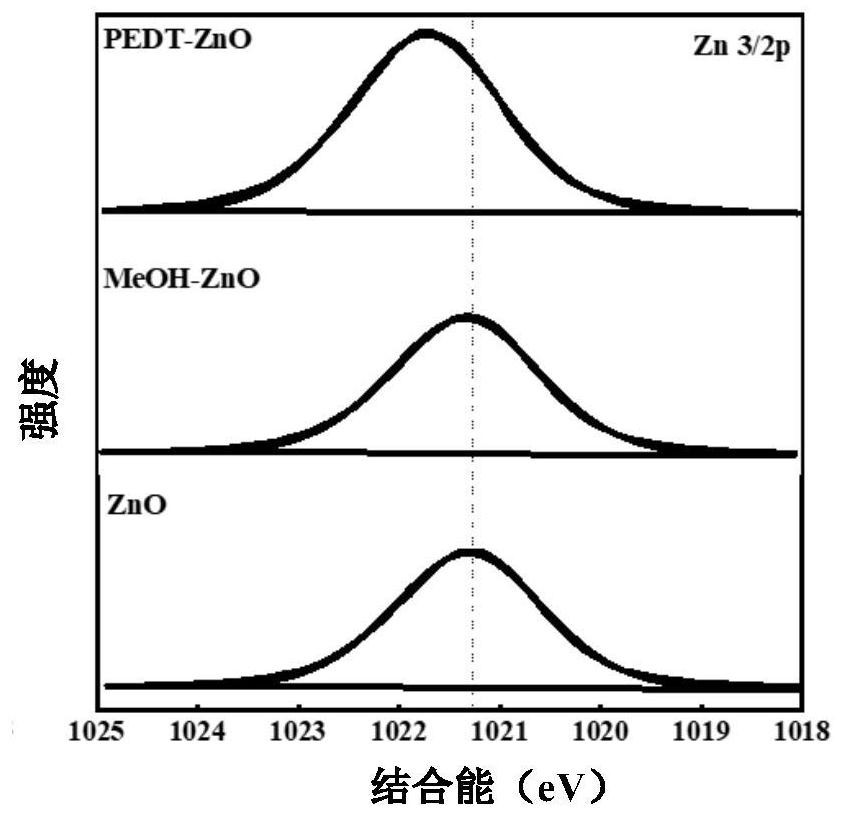

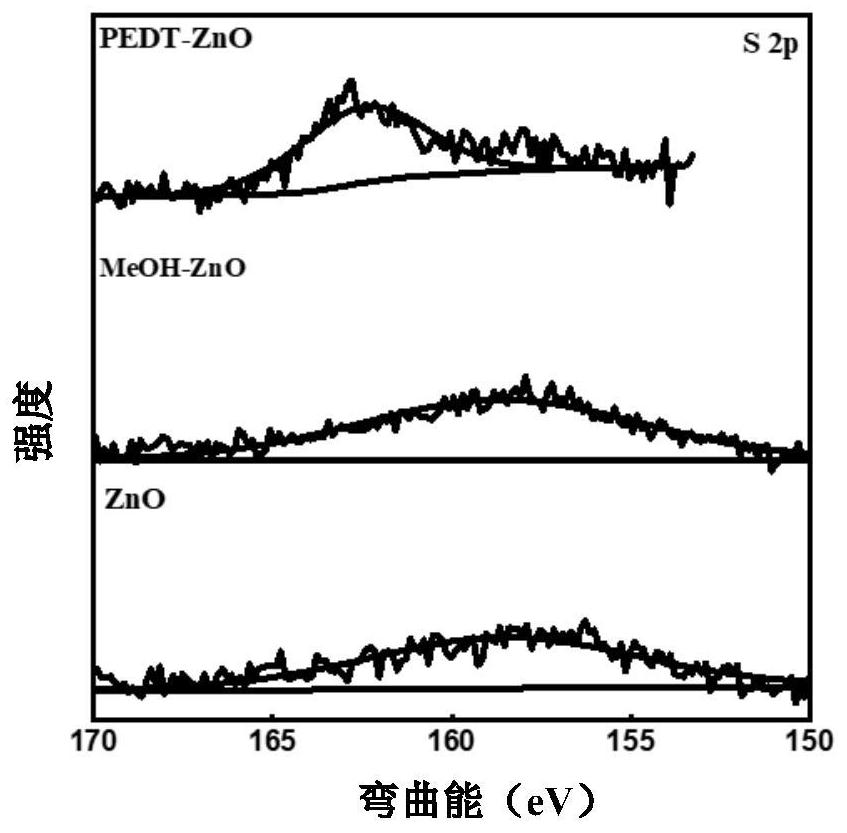

[0029] Modifying the zinc oxide nanoparticle film with a weakly acidic solution, the acidic substances contained in the weakly acidic solution include any one or a combination of two or more of phenylthiol, acetate and biomass acidic compounds .

[0030] In some more specific embodiments, the acetate includes any one or a combination of two or more of zinc acetate, zirconium acetate, copper acetate, and sodium acetate, but is not limited thereto.

[0031] Further, the phenylthiol includes one or a combination of phenylethanethiol and 1,2-benzenedithiol, but is not limited thereto.

[0032] Further, the biomass acidic compound includes any one or a combination of two or more of vitamin C, lactic acid, tartaric acid, and amino acids, but is not limited thereto.

[0033] In some more specific embodiments, the performance and stabili...

Embodiment 1

[0068] Embodiment 1: the preparation of phenylethyl thiol (PEDT) methanol solution treatment zinc oxide thin film 10s and PM7:IT-4F organic solar cell

[0069] (1) Preparation of surface-modified zinc oxide film

[0070] Preparation of ZnO nanoparticles: Weigh 0.66g of zinc acetate dihydrate in a 250mL three-neck flask, add 30mL of dimethylsulfoxide (DMSO) and stir to dissolve; weigh 0.9g of tetramethylammonium hydroxide (TMAH) and Mix 10mL of ethanol, ultrasonicate for 5min until it is completely dissolved, add the ethanol solution of TMAH dropwise with a constant pressure funnel, the dropping time is about 5min, continue to stir for 1h after the dropwise addition is completed, after the reaction, add 125mL of acetone, and continue stirring until The precipitation is complete, and the precipitation obtained by filtration is zinc oxide nanoparticles;

[0071] Preparation of ZnO dispersion: Dissolve the above-mentioned ZnO nanoparticles in 125 mL of acetone and let stand overn...

Embodiment 2

[0103] Embodiment 2: the preparation of phenylethyl thiol (PEDT) methanol solution treatment zinc oxide thin film 10s and PM6:IT-4F organic solar cell

[0104] (1) The preparation of the surface-modified zinc oxide film is the same as in Example 1;

[0105] (2) Preparation of PM6:IT-4F organic solar cells (non-fullerene acceptor group)

[0106] Firstly, use detergent, deionized water, acetone and isopropanol to ultrasonically clean the substrate composed of transparent substrate and indium tin oxide (ITO) transparent conductive bottom electrode, each cleaning time is 30min, and then use nitrogen gas After the substrate is dried, the substrate is treated with a UVO ozone cleaner for 30 minutes;

[0107] Preparation of the electron transport layer on the bottom electrode: the ethanol dispersion of zinc oxide nanoparticles is spin-coated on the bottom electrode with a zinc oxide film with a thickness of 30nm, the spin-coating speed is 3000rpm, and the temperature is dried at 130...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com