Preparation method of Pickering high internal phase emulsion capable of loading astaxanthin for 3D printing

A high internal phase emulsion and dispersion technology, applied in the direction of additive processing, food science, etc., can solve the problems of no portability, low food safety, lack of biocompatibility and biodegradability, etc., and achieve strong stability , the protection of biologically active substances, the effect of excellent rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

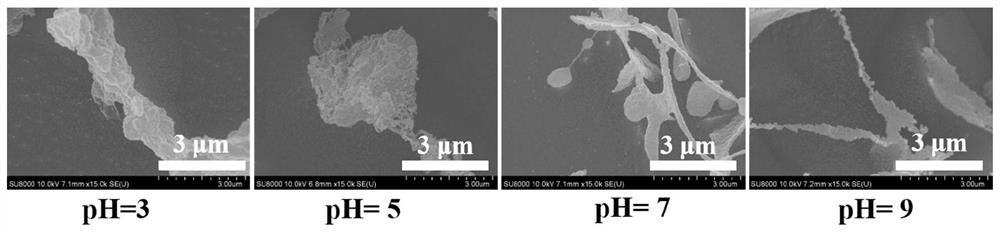

[0057] Embodiment 1: the preparation method of sea bass protein microgel particles

[0058] (1) Mix 500g sea bass meat with 5L of deionized water, and homogenize at 10000rpm for 2min; adjust the pH of the obtained sea bass meat homogenate to 10.5, stir at a rotating speed of 200rpm for 2.5h; centrifuge at 10000rpm for 30min to get the supernatant, The obtained supernatant was adjusted to pH 4.5; at 4° C. for 30 min, centrifuged at 8000 rpm for 15 min to leave a precipitate; after freeze-drying, sea bass protein powder was obtained;

[0059] (2) Prepare a 10wt% sea bass protein solution, stir and dissolve, hydrate at 4°C for 12 hours; adjust pH to 7, and place in a water bath at 80°C for 20 minutes; after cooling to room temperature, add gluten with 20U / g sea bass protein. After aminoamido transaminase, the cross-linking reaction was carried out at 45 °C for 4 hours, and a gel block was obtained after the reaction; 1 time of deionized water was added to the gel block, and a hig...

Embodiment 2

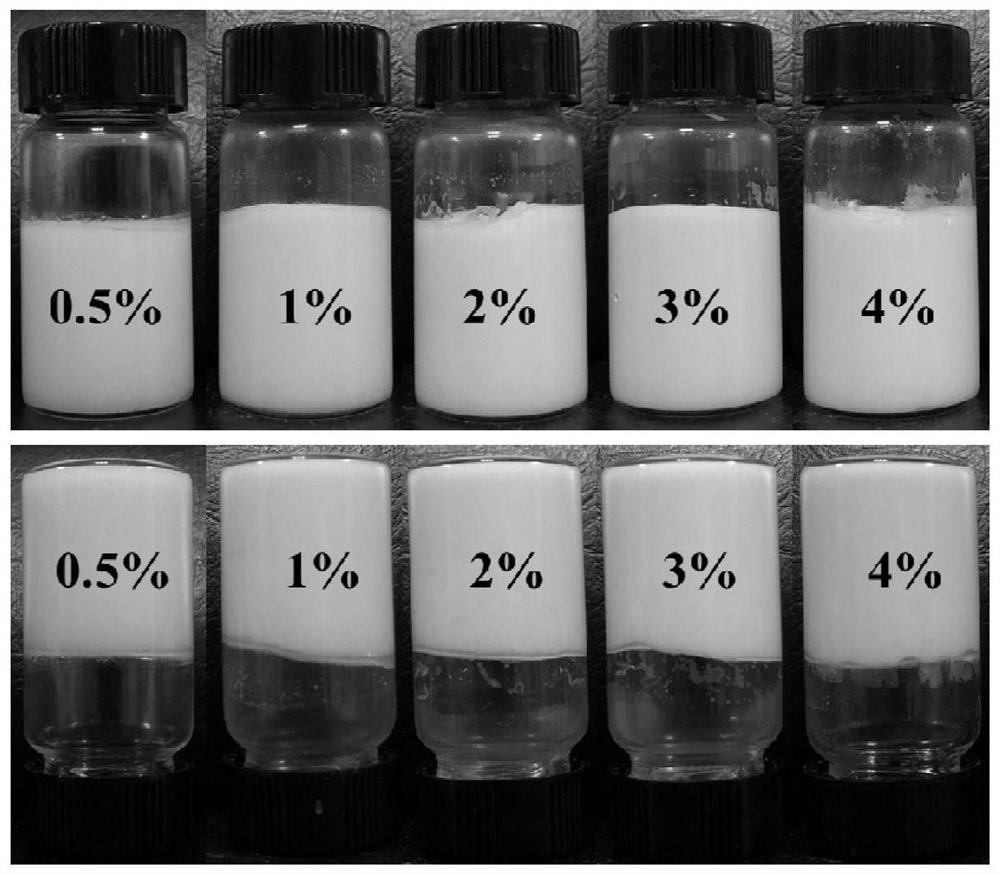

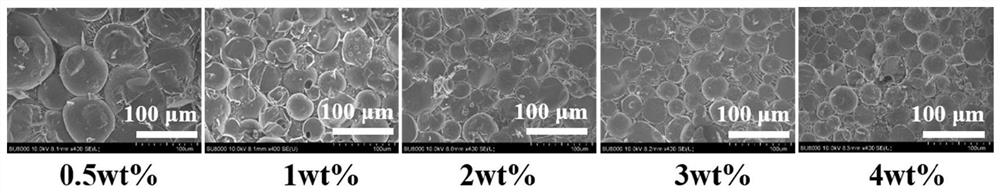

[0062] Example 2: Preparation method of Pickering high internal phase emulsion stabilized by sea bass protein microgel particles

[0063] Get the sea perch protein microgel particle dispersion liquid obtained in step (2) in Example 1, in terms of the sea perch protein concentration, add water and dilute to make the concentration of the microgel particles be 0.5wt%, 1wt%, 2wt%, 3wt%, respectively % and 4wt%, adjust the pH to 7; select corn oil as the oil phase; mix the diluted sea bass protein microgel particle dispersion with corn oil in a volume ratio of 2:8; the mixture is subjected to high-speed shearing, high-speed The rotating speed of shearing is 10000 rpm, and the shearing time is 2 min to obtain Pickering high internal phase emulsion with stable sea bass protein microgel particles.

[0064] Performance Testing:

[0065]In this example, the appearance diagram of the fresh Pickering high internal phase emulsion prepared by sea bass protein microgel particles with differ...

Embodiment 3

[0073] Example 3: A preparation method for 3D printing astaxanthin-loaded Pickering high internal phase emulsion

[0074] Get the sea bass protein microgel particle dispersion liquid obtained in step (2) in Example 1, in terms of sea bass protein concentration, add water and dilute to make the concentration of the microgel particles be 0.5wt%, 1wt%, 2wt%, 3wt% respectively % and 4 wt %, adjust pH to 7; select corn oil as the oil phase, dissolve 0.1 wt % of astaxanthin in corn oil; mix the diluted microgel particle dispersion with astaxanthin-containing corn oil according to the Mixing in a volume ratio of 2:8; and then performing high-speed shearing at a speed of 10,000 rpm and a shearing time of 2 min to obtain astaxanthin-loaded sea bass protein microgel particles stable Pickering high internal phase emulsion.

[0075] Performance Testing:

[0076] like Figure 10 Shown is the effect of sea bass protein microgel particles on the ability of Pickering high internal phase emu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com