Catalyst based on three-way catalyst ceramic carrier and preparation method thereof

A three-way catalytic converter and ceramic carrier technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor adhesion and durability of catalytic active components, and affect the catalytic effect, etc., to achieve Shorten the grinding time, improve the effective utilization rate, and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

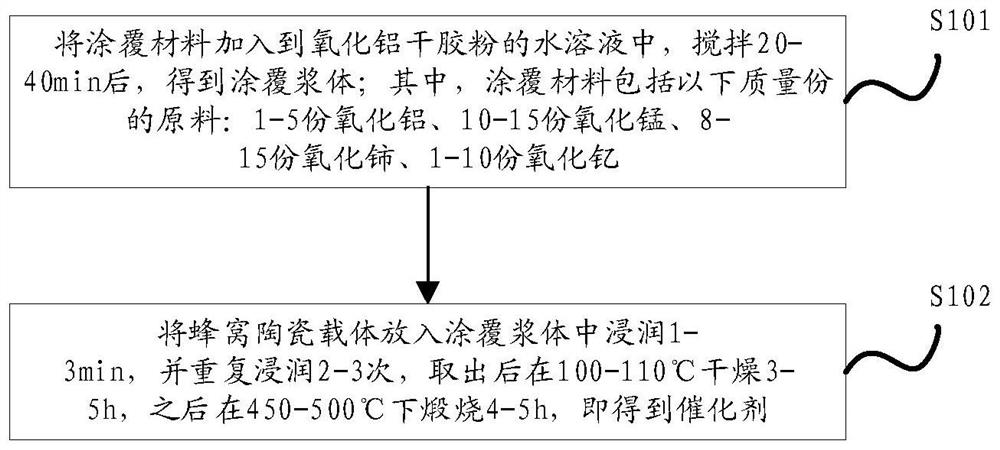

[0032] figure 1 It is a schematic flow diagram of a preparation method of a catalyst based on a three-way catalyst ceramic carrier of the present application, refer to figure 1 , the preparation method of the catalyst provided by the application comprises the following steps:

[0033] In step S101, the coating material is added to the aqueous solution of the alumina dry rubber powder, and after stirring for 20-40 min, a coating slurry is obtained; wherein, in parts by mass, the coating material includes: 1-5 parts of alumina, 10 -15 parts of manganese oxide, 8-15 parts of cerium oxide, 1-10 parts of yttrium oxide; the pore volume of the alumina dry rubber powder is not less than 1 mL / g, and the weight ratio of the coating material to the aqueous solution of the alumina dry rubber powder is 1 : (2.5-3.2), the mass fraction of the aqueous solution of the alumina dry rubber powder is 15wt%-20wt%;

[0034]Step S102, using 10wt% nitric acid to have a density of 2.1-2.2g / cm 3 The...

Embodiment 1

[0042] Embodiment 1 of the present application provides a preparation method of a catalyst based on a three-way catalyst ceramic carrier, comprising the following steps:

[0043] Preparation of coating material: Add citric acid to a mixed solution of aluminum nitrate, manganese nitrate, cerium nitrate, yttrium nitrate and water at 70 °C, stir and place at 105 °C for 8 hours, fully grind and then calcine at 450 °C for 4 hours, that is, The coating material is obtained; the mass parts of each substance in the coating material are: 1 part of aluminum oxide, 10 parts of manganese oxide, 8 parts of cerium oxide, and 1 part of yttrium oxide; the weight ratio of citric acid, water and aluminum nitrate is 1:3 :1;

[0044] The coating material was added to the aqueous solution of 15 wt % alumina dry rubber powder, and after stirring for 20 minutes, a coating slurry was obtained; the weight ratio of the coating material and the aqueous solution of the alumina dry rubber powder was 1:2.5...

Embodiment 2

[0047] Embodiment 2 of the present application provides a method for preparing a catalyst based on a three-way catalyst ceramic carrier, comprising the following steps:

[0048] Preparation of coating material: Add citric acid to a mixed solution of aluminum nitrate, manganese nitrate, cerium nitrate, yttrium nitrate and water at 80°C, stir and place at 110°C for 5h, fully grind and then calcine at 550°C for 3h, that is, The coating material is obtained; the mass parts of each substance in the coating material are: 5 parts of aluminum oxide, 15 parts of manganese oxide, 15 parts of cerium oxide, 10 parts of yttrium oxide; the weight ratio of citric acid, water and aluminum nitrate is 3:4 :1;

[0049] The coating material was added to the aqueous solution of 20wt% alumina dry rubber powder, and after stirring for 40 minutes, a coating slurry was obtained; the weight ratio of the coating material and the aqueous solution of the alumina dry rubber powder was 1:3.2;

[0050] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com